Overview

The servo press kit and its associated application software can be used to respond quickly and flexibly to a range of press processes. It is a great alternative to complex and often oversized presses. The software can be used for continuously monitoring parameters such as moments of force and displacement during joining and press-fitting processes.

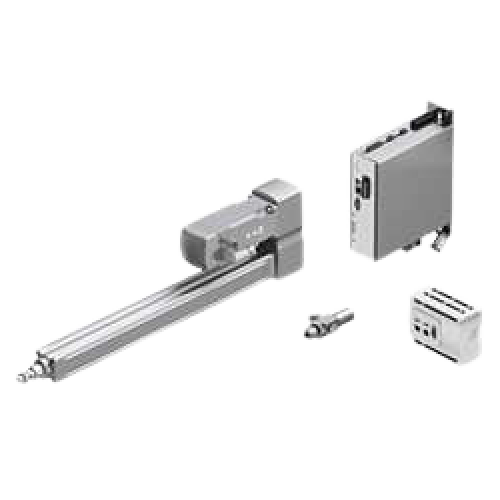

The electric cylinder, axial and parallel kit and servo motor are assembled in one application-specific module. This reduces the number of individual components to be managed. This module can be directly integrated in the system thanks to defined mechanical and electrical interfaces. After completion, a full performance test is performed. There is thus no need for you to carry out any assembly process.

Watch the video to see the basic setup of the Servo press kit in just five minutes, and learn of potential application uses.

Watch the video to see the basic setup of the Servo press kit in just five minutes, and learn of potential application uses.

Advantages

- Pressing forces up to 17 kN (higher force ranges on request)

- Very high positioning and repetition accuracy

- Ideal price/performance ratio

- Easy integration into any application

Individual Components

- Servo motor

- Electric cylinder

- Force sensor (inc. inspection record)

- Software package

- Motor controller

- Controller (inc. microSD memory card)

Areas of Application

- Press-fitting and pressing

- Machining

- Bending

- Riveting

- Testing springs

- Bevelling

- Punching

- Stamping

- Deep drawing

- Straightening

Frequently Asked Questions (FAQs)

Build innovative machines faster without costly prototyping with Efficient Motion Control.

With Effective Motion Control, machine builders can easily overcome major challenges and enable faster time-to-market, increased functionality, resolve complex system requirements, and demands for safety and sustainability.