Monitor Systems

Delivering Integrated Control, Safety & Communication Systems for the OBANA Heavy Lift Jack-Up Vessel

Monitor Systems specialises in the design, construction, and installation of advanced electrical and electronic control and monitoring instrumentation systems for vessels in the energy sector. These include jack-ups, semi-submersibles, platforms, drillships, support vessels, and FPSOs, all delivered to industry-compliant standards.

Project Background

Why the need?

The OBANA heavy lift jack-up vessel is a specialised offshore asset, purpose-built for decommissioning operations. What began as a minor support task – assisting the owner in restoring a legacy RPD system originally supplied to Transocean rigs in the early 2010s – quickly evolved into a comprehensive programme of work.

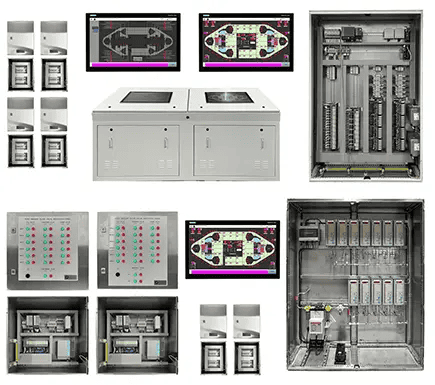

Monitor Systems was commissioned to deliver a full suite of modernised systems covering vessel control, safety, and communications. The expanded scope included tank gauging, preload control, watertight door monitoring, bilge monitoring, Emergency Shutdown (ESD) and alarm systems, as well as a vessel-wide fibre optic backbone.

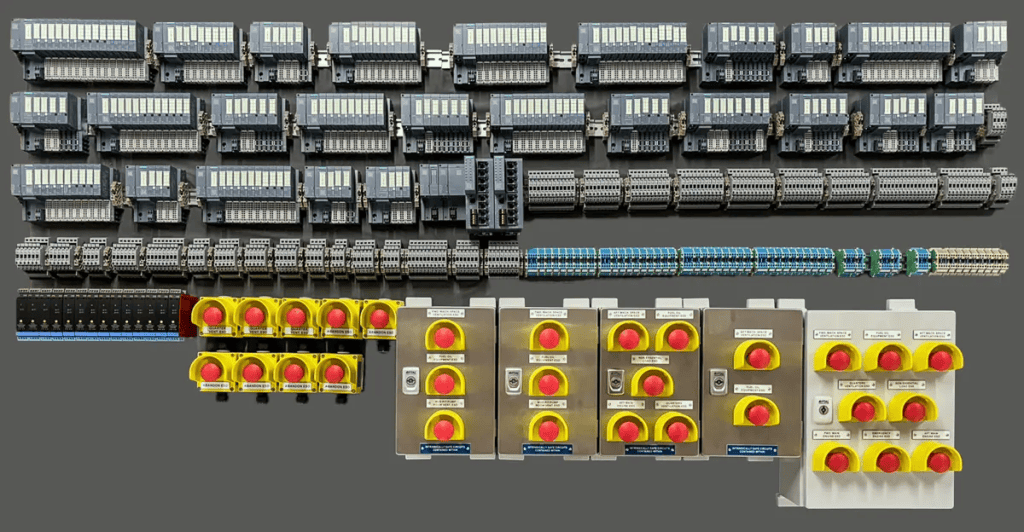

As Monitor Systems’ long-standing automation partner, Parmley Graham (PG) supplied the Siemens-based hardware and industrial networking components that formed the foundation of this extensive modernisation effort. This included:

- Siemens S7-1500 PLCs (both standard and redundant) with ET 200SP I/O,

- Redundant SCADA servers with multiple clients, MTP HMIs, Unified PC Runtime licences, and

- SCALANCE industrial networking components, including fibre SFPs.

While Monitor Systems led the design, engineering, and integration, PG played a crucial supporting role by offering expert guidance on product availability, responding swiftly to replacement part requests, and ensuring dependable delivery to meet the project’s evolving demands.

Project Challenges:

The OBANA upgrade posed a complex set of technical and logistical challenges. Monitor Systems was tasked with:

- Integrating legacy systems with new distributed control hardware.

- Expanding and adapting preload, tank gauging, watertight door, bilge monitoring and ESD/alarm systems.

- Delivering system redundancy and high availability to ensure offshore operational safety.

- Managing evolving scope while maintaining procurement and delivery timelines.

These demands highlighted the critical importance of a resilient supply chain and a reliable hardware platform.

Collaboration in Action:

Collaboration between Monitor Systems and PG was instrumental throughout the project. During the procurement phase, PG ensured clear and responsive communication, delivering rapid turnaround on enquiries, transparent lead times, and adaptable module exchanges as the scope evolved.

This dependable support empowered Monitor Systems to confidently expand the project mid-delivery, assured of hardware availability and supply chain resilience. The result was a streamlined procurement process that mitigated risks and kept the project firmly on track.

Solution Impact

The OBANA project successfully delivered a fully integrated, future-ready control and safety infrastructure, with tangible results including:

- Integration of over 3,000 I/O points across vessel systems.

- More than 400 offshore support days and 3,500+ engineering hours

- Seamless interfacing between legacy systems and new distributed architectures.

- High operational reliability enabled by redundant PLCs and SCADA servers.

- Certified vessel-wide fibre optic backbone, ensuring scalability and ease of future upgrades.

PG’s dependable supply of Siemens automation technology was pivotal in meeting project timelines, achieving performance targets, and securing long-term operability.

“The OBANA project demanded seamless integration of legacy and modern systems, all while maintaining high availability and redundancy. Having Parmley Graham as a trusted partner assured us that critical hardware would arrive on time, enabling us to focus on engineering and integration. Their dependable support played a key role in the overall success of the vessel upgrade.”

Darren Milne, Commercial Manager, Monitor Systems.

“Supporting Monitor Systems on the OBANA project was about more than hardware supply - it was about being a responsive and reliable partner. By providing fast turnaround on enquiries, clear visibility on lead times, and flexibility as the scope evolved, we ensured that Monitor Systems had the confidence to deliver such a complex and high-profile offshore upgrade.”

Doug Benton, UK Sales Manager, Parmley Graham.

Lessons Learned

This project reinforced the value of standardising on proven, well-supported hardware platforms. The original Siemens-based RPD system – still operational more than a decade after installation – demonstrated the enduring reliability of Siemens automation technology, validating the decision to continue building on this foundation.

Future

The OBANA upgrade exemplifies how complex offshore modernisation can be achieved through strong supplier collaboration, reliable delivery, and robust technology choices. Monitor Systems showcased its capability to deliver integrated, high-performance solutions in demanding environments, while PG’s Siemens supply chain provided the flexibility and confidence needed to adapt to evolving scope and deliver offshore success.

Get in Touch

To discuss how the PG team can help, either email us at support@parmley-graham.co.uk or call 0191 478 0404.

Alternatively, click the button and complete your details: