Sustainability and Energy Efficiency

Do you know how to make your company more sustainable and energy-efficient?

Industry challenge overview

Sustainability and Energy Efficiency

Did you know that:

Industry is responsible for 24% of Greenhouse Gas emissions?

and that:

Until 2030, GHG emissions are supposed to drop by about 55% by law and there will be a pilot with CO2-tax/penalty.

Imagine…

When energy prices are high, it’s all the more important that your production facilities’ power and resource consumption are as transparent as possible, and that you take control of load peaks that can otherwise result in hefty fines.

Add to this the fact that more and more customers, partners, and legislators are looking for sustainable partners who can demonstrate the carbon footprint – but you lack transparency and don’t know where to start.

Can you do it all? Use the step towards sustainability as an opportunity – get in touch!

For your specific requirements, talk to us.

To see how we can help with your systems or if you have any enquiry, please get in touch – we’ll be pleased to help. Send us an email at support@parmley-graham.co.uk or fill the form below.

Register for Transform 2024 - Siemens must-attend event of the year!

Having flexible solutions for different resources and connecting them is the key to sustainability and efficiency!

Use data for better transparency

- Improves resource transparency and consumption.

- Enables process optimisation during low production times.

- Enhanced data overview along the material flow for the aggregation of CO2 emissions.

Use standardised processes for effective analysis

- Reduces data silos and enables data-driven decisions.

- Better comparison on machine, cell or plant level.

- Integrating sustainable products to get a certificate for standard norms like ISO 5000.

Energy-efficient production

Optimising energy use, and reducing CO₂ emissions:

With energy-efficient production, industry can contribute greatly to a sustainable reduction in CO₂ emissions without limiting productivity – in fact, quite the opposite!

As energy is a decisive competitive factor, regardless of the industry, there is no alternative to increasing energy efficiency.

It is a great challenge – but also a great opportunity because by making plants more energy-efficient, companies can also achieve considerable cost savings!

Energy efficiency in production – in reality

Energy-efficient production means more than simply reducing energy consumption, CO₂ emissions, or costs – it also involves linking energy and production data to analyse and optimise not only energy consumption but also the energy productivity of machines, plants, and processes. These measures provide the opportunity to achieve all-round improvements in process productivity and efficiency.

Energy Transparency

Transparent visualisation of energy data

Question:

Do two similar machines consume different amounts of energy?

Answer:

Measuring devices are installed on both machines to record and evaluate the consumption data. The analysis shows that machine A requires more energy for vacuum operation and the conveyor belt requires more electrical energy.

The solution for greater efficiency:

A leakage in the vacuum system is identified and repaired. A motor with a defective bearing is identified on the conveyor belt and is replaced with a more efficient motor during its next maintenance.

Assessment and Analysis of Machines

Assessing and analysing the energy efficiency of machines

Question:

I want to purchase a new machine. How can I compare the consumption performance of the machines on offer and reduce energy consumption that does not contribute to added value?

Answer:

Using an appropriate solution, energy consumption can be ascribed to the individual energy operating states (off, standby, ready for operation, in operation) and evaluated and compared accordingly.

The solution for greater efficiency:

Machine suppliers can provide their customers with an energy consumption profile (standardised acceptance form) during the purchasing phase. Actual energy consumption on-site can be analysed using a reference measurement. Using key energy performance indicators (EnPI) and benchmarks, all machines can be evaluated continuously and comprehensively and appropriate optimisation measures can be implemented, e.g., adaptation of the standby mode.

Energy Optimisation

Meeting requirements, identifying savings potential, optimising contracts

Question:

How can I identify the savings potential in my operations, optimise my contract with the energy supplier, reduce my tax payments, and benefit from state subsidies?

Answer:

Introduce a certified energy data management system in production that reports and archives energy data following legal requirements (e.g., ISO 50001).

The solution for greater efficiency:

Identifying the major energy consumers allows you to avoid energy peaks. An automated load management system can automatically shut down systems and make them available again. Forecasting the expected load profile enables you to negotiate an optimized contract with the energy supply company. Transparent energy consumption helps make personnel more aware of energy efficiency within the company, and energy efficiency measures and targets such as the annual increase in energy efficiency can be tracked and verified.

Energy-efficient production

High energy consumption places companies under increasing regulatory and cost pressure.

Discover the solutions we are already using today to shape the energy-efficient production processes of tomorrow:

The solution

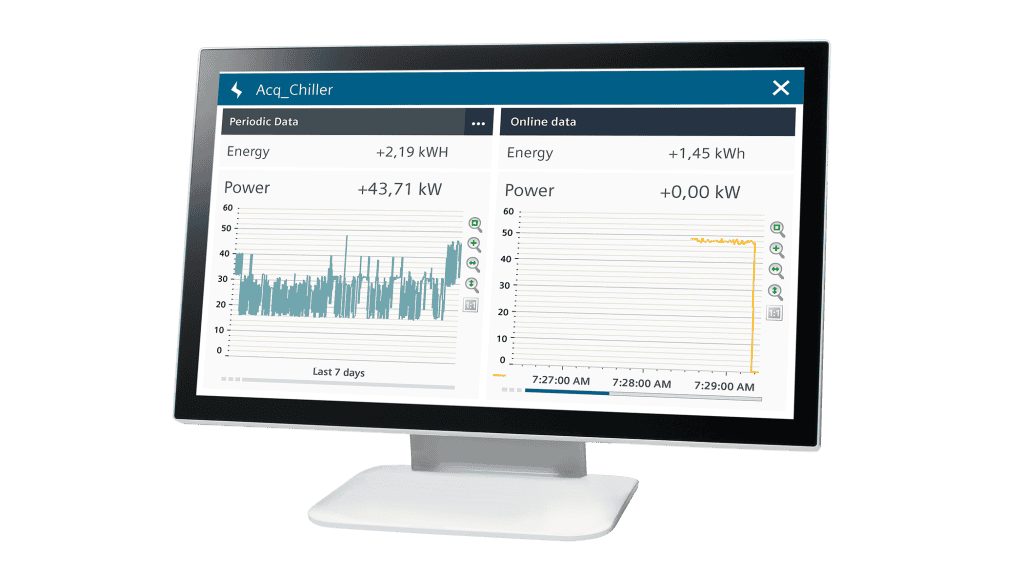

SIMATIC Energy Suite

With the SIMATIC Energy Suite, you can manage the energy consumption of your plants: from data acquisition to proactive load management.

Energy transparency in production – Prove the energy efficiency of your machines and plants in detail. Monitor the agreed capacity limits for electrical energy and avoid fines with load management. Simple and integrated into automation with SIMATIC Energy Suite and S7 Energy Efficiency Monitor.

Simple and integrated energy management

From the measurement of individual loads to detailed evaluation of the efficiency of entire machines, SIMATIC Energy Suite and the S7 Energy Efficiency Monitor bring energy transparency to your automation system. In addition, you can use load Management in Energy Suite to avoid peak loads in industrial applications and distribute loads evenly. The engineering integrated into TIA Portal supports you with the simple implementation of production-level energy monitoring.

Register for Transform 2024

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham is a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.