A heavy-duty zero-speed, non-conducting alarm switch - providing cost-effective equipment protection even in the harshest conditions.

SITRANS WM100 motion sensor operates where other systems are prone to failure. The non-contacting design eliminates the need for lubricating, cleaning and part replacement. Downtime and clean-up expenses associated with conveying equipment failure are reduced by the SITRANS WM100. Failure alarms minimize spillage and prevent extensive damage. The SITRANS WM100 can prevent fires caused by belt slippage at the head pulley and warn against conveyor malfunction.

The SITRANS WM100 has built-in selectable start delays and 1 Form C relay contact. With an aluminum body, it operates from -40 to +60 °C (-40 to +140 °F).

Key Applications: tail pulleys, driven pulleys, motor shaft sensing, screw conveyor flights, bucket elevators

Technical Specifications

SITRANS WM100 | Power Supply

| 115 V AC/50 to 60 Hz, 7 VA 230 V AC/50 to 60 Hz, 7 VA ± 10 % of rated voltage |

|---|---|

Inputs

| – |

Outputs

| 1 SPDT Form C relay |

Operating Temperature

| -40 to 60 °C (-40 to 140 °F) |

Enclosure

| Aluminum 2″NPSL process mounting |

Design

Mounting

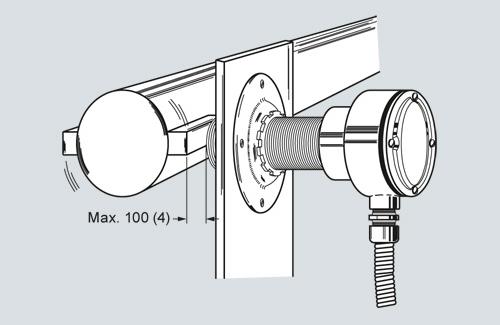

The WM100 probe should be mounted, using the supplied mounting flange, onto a vibration-free structure. The gap between the probe and the target should be sufficient such that there is no danger of the target damaging the probe. The maximum allowable gap is 100 mm (4 inch) from the face of the target to the face of the probe for 4.5 x 4.5 mm (3/16 x 3/16 inch) keyway. The WM100 is sensitive to lateral disturbances to its magnetic field. If the WM100 is responding to motion from an interfering target, move the WM100 or install a ferrous plate (steel) as a shield between the WM100 and the interfering target. Where possible, the probe should be mounted such that the cable inlet is pointing downward to avoid accumulation of condensation in the casing. Connection of the probe should be made via flexible conduit for easier removal or adjustment of the probe.

Application

This rugged unit is impervious to dust, dirt, build-up and moisture and is ideal for such primary industries as mining, aggregate, and cement. Operating where other systems are prone to failure, the non-contacting design eliminates the need for lubricating, cleaning and part replacement. Downtime and clean-up expenses associated with conveying equipment failure are reduced by the SITRANS WM100. It alarms to minimize spillage, prevent extensive damage or even fire caused by belt slippage at the head pulley, and warns against conveyor malfunction.

The SITRANS WM100 has built-in selectable start delays and 1 Form C relay contact. With an aluminum body, it operates from ‑40 to +60 °C (‑40 to +140 °F).

- Key Applications: tail pulleys, driven pulleys, motor shaft sensing, screw conveyor flights, bucket elevators

The SITRANS WM100 Advantage

- Up to 100 mm (4 inch) gap between SITRANS WM100 and targets

- Rugged, low maintenance suitable for tough environments

- 1 SPDT Form C relay contact

- Provides cost-effective protection

- Visual indication of target triggered pulse

Build innovative machines faster without costly prototyping with Efficient Motion Control.

With Effective Motion Control, machine builders can easily overcome major challenges and enable faster time-to-market, increased functionality, resolve complex system requirements, and demands for safety and sustainability.

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham is a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.