Siemens Pressure Measurement

Parmley Graham offers Siemens’ range of pressure measurement solutions designed for accurate and reliable measurement in industrial and commercial applications. Tailored to the specific requirements of your applications, Siemens pressure measurement devices provide the confidence you need in your instrumentation control.

Siemens’ primary pressure measurement line is branded under the SITRANS P series. The SITRANS P series includes various models, providing different types of pressure measurements such as absolute, gauge, and differential pressure.

Reliable. Accurate. Versatile. Low-maintenance.

Pressure Measurement under control with SITRANS P

Every process in your plant brings with it specific requirements. That’s why SITRANS P pressure transmitters are your complete range of measuring products with different levels of performance, varying load capacities and types of materials.

Uncompromising precision

SITRANS P pressure transmitters are a complete family of measuring instruments. They measure gauge, differential, and absolute pressure, including performance values, load capacities, and materials.

In addition to high measuring accuracy and ruggedness, the modular system features superb operating convenience and functionality. Whether it’s international approvals or industry standards, these transmitters meet the challenges of increasingly complex tasks in the process industries.

Safety included

You can select device versions that also offer comprehensive safety features. Warnings and alarms signal critical measured values for plant monitoring, while service or calibration intervals can be displayed predictively through self-diagnostics based on a maintenance scheduler.

Safety is integrated

Stringent safety requirements must be met in all areas and sectors of the process industries. One example is chemicals, and Siemens’ portfolio for pressure measurement unequivocally satisfies the high demands of the chemical industry (SIL 3). Thanks to comprehensive diagnostic functions, you always know whether your process is running according to plan and can intervene and correct it, if necessary, for example in reactors. They are part of the overall plant and must be seamlessly integrated into the process for maximum safety, efficiency, and availability. Interventions such as filling, heating, cooling, mixing, and the monitoring of all process conditions are performed on an ongoing basis. In addition, parameters such as pump performance, temperature, energy consumption, and emissions must be measured, analysed, and monitored.

SITRANS P Pressure Transmitters - Your complete range of measuring devices.

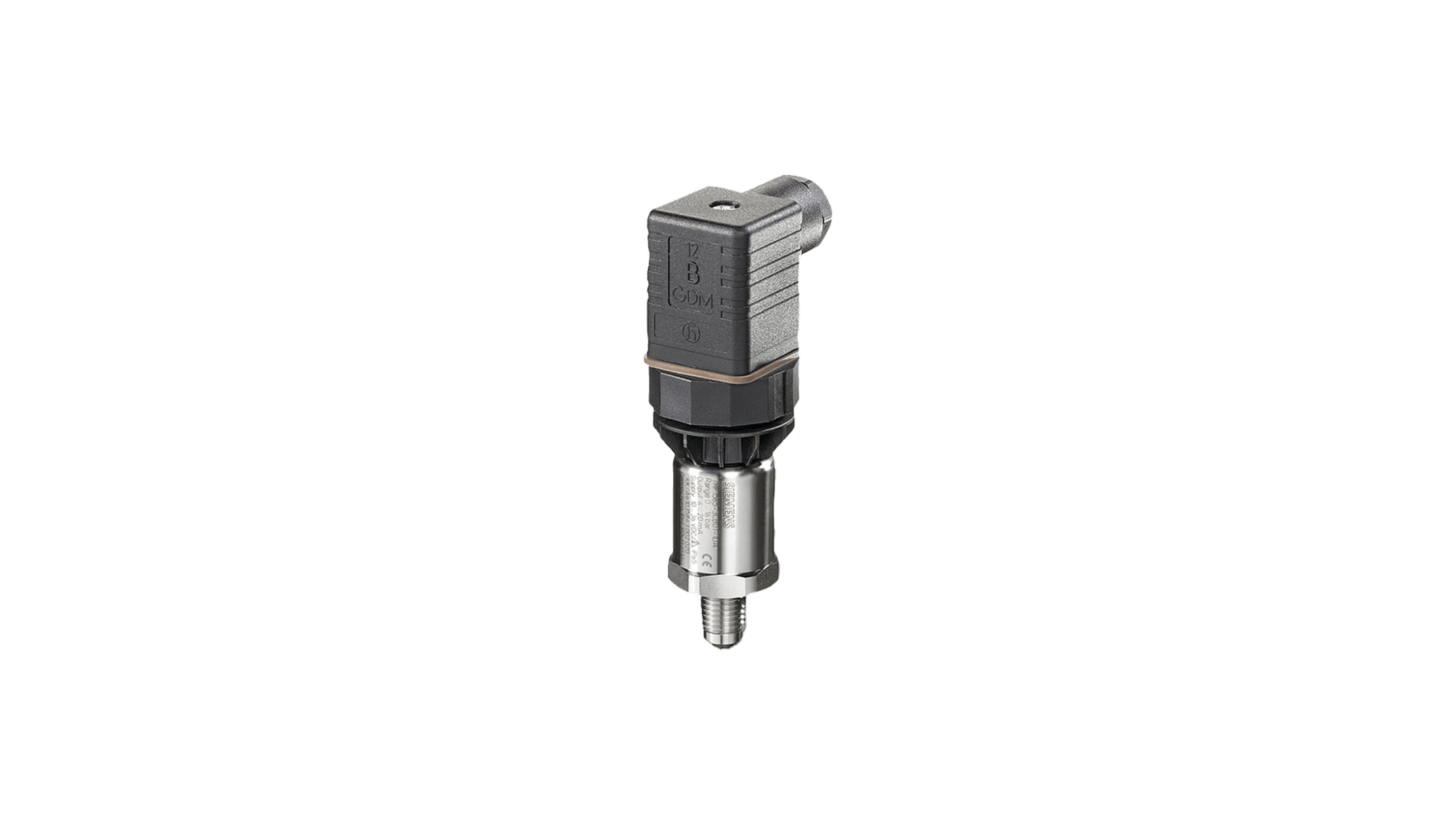

“High performance” version of the P320 for gauge and differential pressure measurements.

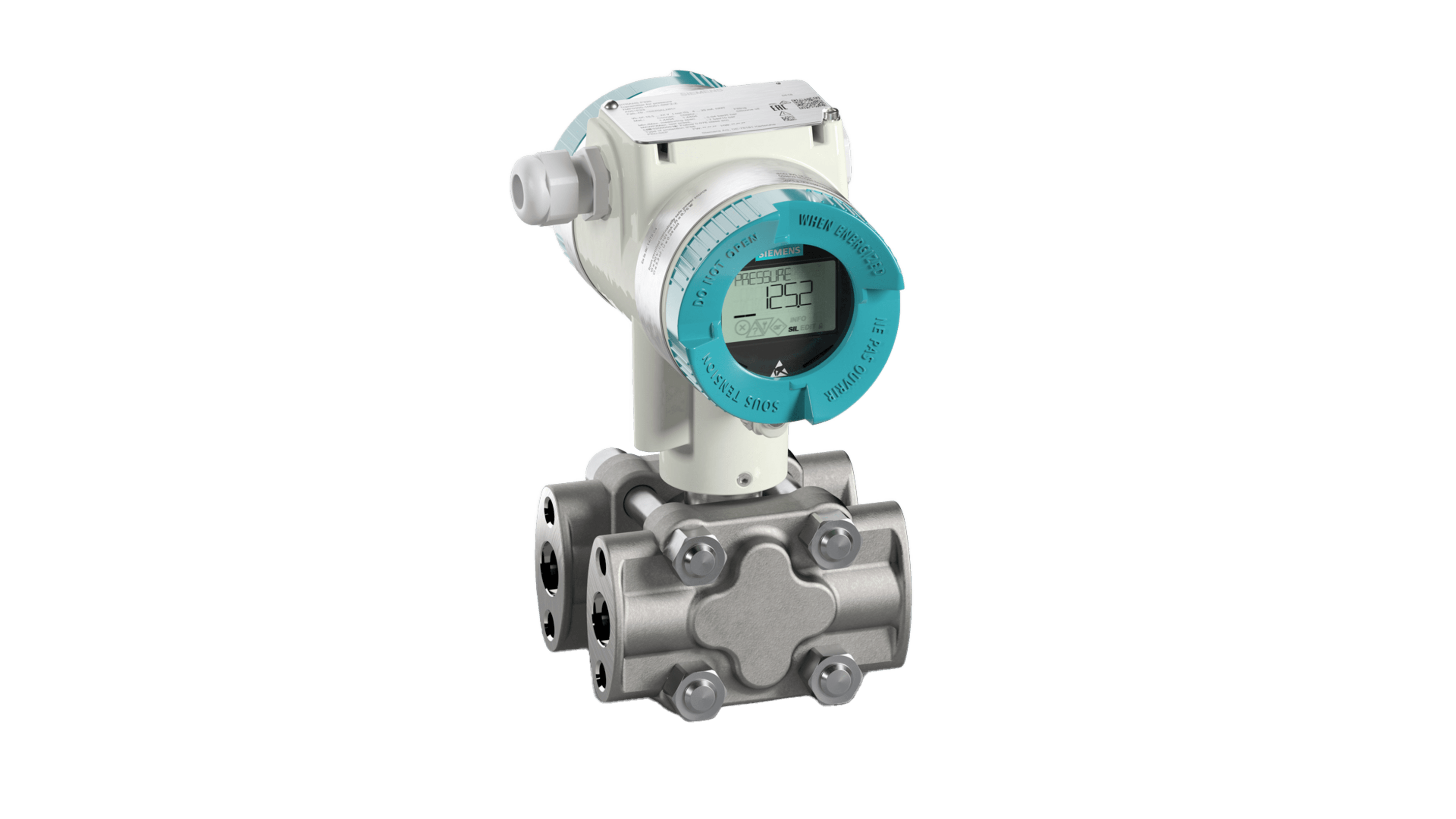

For measurement of gauge pressure, absolute pressure, differential pressure, flow, and level.

Converting the level-proportional hydrostatic pressure into standardised signal 4 to 20 mA.

Submersible sensor for hydrostatic level measurement with protective caps made of PPE, stainless steel and ETFE.

Accessories

Seals, Valves and Valve Blocks

We offer a range of fittings accessories for your pressure applications. These include:

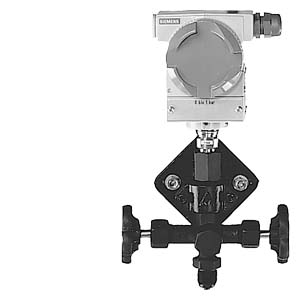

- Shut-off Valves for gauge and absolute pressure transmitters

Used for shutting off and venting the measured medium line and for checking the connected pressure measuring device, gauge pressure transmitter or absolute pressure transmitter. - Shut-off valves for differential pressure

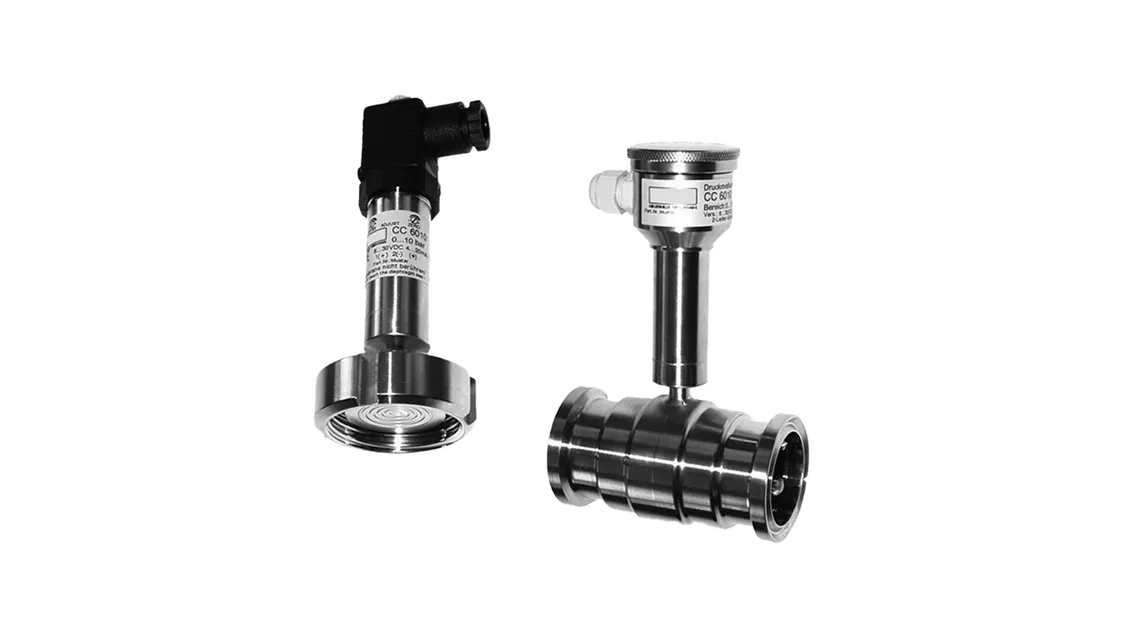

The shut-off valves for differential pressure transmitters are used for shutting off and venting the measured medium lines and for checking the connected differential pressure transmitter. - Remote Seals

For measuring viscous, corrosive or fibrous media (plus media at extreme temperatures). The remote seals can be used with the following pressure transmitters:- SITRANS P320/420

- SITRANS P300

Please contact us to speak to one of our Process Instrumentation specialists for advice on meeting your requirements or complete the form below.

SITRANS P Remote Seals

“High performance” version of the P320 for gauge and differential pressure measurements.

For measurement of gauge pressure, absolute pressure, differential pressure, flow, and level.

SITRANS P Valves / Fittings

Shut-off valves acc. to DIN 16270, DIN 16271 and DIN 16272

“High performance” version of the P320 for gauge and differential pressure measurements.

For measurement of gauge pressure, absolute pressure, differential pressure, flow, and level.

The SITRANS P Advantage

For gases, liquids, and paste-like media, the gauge pressure, absolute pressure, and differential pressure must be measured constantly to detect values that are too low or a potential overload. Whether for pipelines, valves, or reactors, the SITRANS P transmitter family offers the right solution for every application.

The most important factor in selecting the right pressure transmitter is the required accuracy of the measuring range. SITRANS P transmitters offer a variety of choices from 0.04% to 0.3%. They are suitable for safety-related applications, with certifications according to SIL2 and SIL2/3. Numerous bus systems for communication are also supported, including HART®, PROFIBUS PA, and FOUNDATION Fieldbus. In addition, the transmitters have all the most current approvals and certificates. Our pressure measuring devices give you the instrumentation reliability you need to meet your own specific requirements.

- High process quality thanks to reliable measured values, even after years of operation

- Superior communication capabilities based on industry standards such as 4…20mA, HART®, PROFIBUS PA, and FOUNDATION Fieldbus

- Seamless integration in SIMATIC PCS 7 thanks to specific faceplates and special support from the SIMATIC PDM

(Process Device Manager) central maintenance station - Support for parameterisation, commissioning, diagnostics, and maintenance for all current process control systems thanks to EDD, DTM, and FDI packages

- Devices for SIL applications up to Level 2/3 can be used

- Rugged enough for use in difficult environmental conditions

Key benefits

- All applications supported thanks to a highly diverse portfolio

- Meet all current explosion protection requirements

- High product variance thanks to standard options and customisations

- A variety of materials and process connection options available, including stainless-steel enclosure versions

- Expanded diagnostics

- Maintenance benefits

The SITRANS P range comparison

SITRANS | P420 | P320 | P300 | P Compact | P200/210/220 | LH100 | LH300 |

|---|---|---|---|---|---|---|---|

Pressure Types | Gauge pressure, absolute pressure, differential pressure |

Gauge pressure, absolute pressure, differential pressure |

Gauge pressure, absolute pressure | Gauge pressure, absolute pressure | Compact single-range transmitter for measuring absolute and gauge pressure | Pressure transmitter for measuring hydrostatic levels | Submersible sensor for hydrostatic level measurement |

Measuring span | 1 mbar to 700 bar

| 1 mbar to 700 bar | 10 mbar to 400 bar | 0 mbar to 40 bar | 100 mbar to 1000 bar | 0–3 mH2 O to 0–20 mH2 O | 0–1 mH2 O to 0–40 mH2 O |

Communication | 4…20 mA/HART®, PROFIBUS PA, FOUNDATION Fieldbus (in preparation)

| 4…20 mA/HART®, PROFIBUS PA, FOUNDATION Fieldbus (in preparation) | 4…20 mA/HART®, PROFIBUS PA, FOUNDATION Fieldbus | 4…20 mA; 0…20 mA | 4…20 mA | 4…20 mA | 4…20 mA |

Accuracy1) | 0.04% | 0.065% | 0.075% | 0.2% | 0.25% | 0.25% | 0.15% |

Max. turndown | 100:1 | 100:1 | 100:1 | – | – | – | – |

Long-term stability | 0.125% / 5 years 2) | 0.125% / 5 years 2) | 0.25% / 5 years 2) | 0.2% year | 0.25% year | 0.25% year | 0.15% year |

Measured medium temperature | -40 °C to +100 °C | -40 °C to +100 °C | -40 °C to +200 °C | -10 °C to +200 °C | -30 °C to +120 °C | -10 °C to +80 °C | -10 °C to +80 °C |

Certificates / approvals | ATEX, Exia/ib, Exd, FM is/xp, CSA is/xp, NEPSI, SIL, … | ATEX, Exia/ib, Exd, FM is/xp, CSA is/xp, NEPSI, SIL, … | ATEX, Exia/ib, FM is/xp, CSA is/xp, NEPSI, … | ATEX, Exib | ATEX, Exia, EAC, GL, BV, ABS, UL | ATEX, Exia, IEC Ex, EAC, UL, WRAS | ATEX, Exia, IEC Ex, EAC, UL, WRAS |

Diaphragm materials | Stainless steel, hastelloy, tantalum, monel, gold | Stainless steel, hastelloy, tantalum, monel, gold | Stainless steel, hastelloy | Stainless steel | Ceramic, stainless steel | Ceramic | Ceramic |

Special features | Remote safety handling, ready for digitalization | Remote safety handling | – | – | – | – | – |

For more information, contact us via email at support@parmley-graham.co.uk, or call us directly on 01914780404. Alternatively, you can send us your enquiry by filling the form below:

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham is a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.