LVS and LVL Series

Adaptive, efficient, and essential. Siemens vibrating level switches detect high, low, and demand levels for liquids and solids. They perform in extreme conditions and benefit many industries.

Application highlights

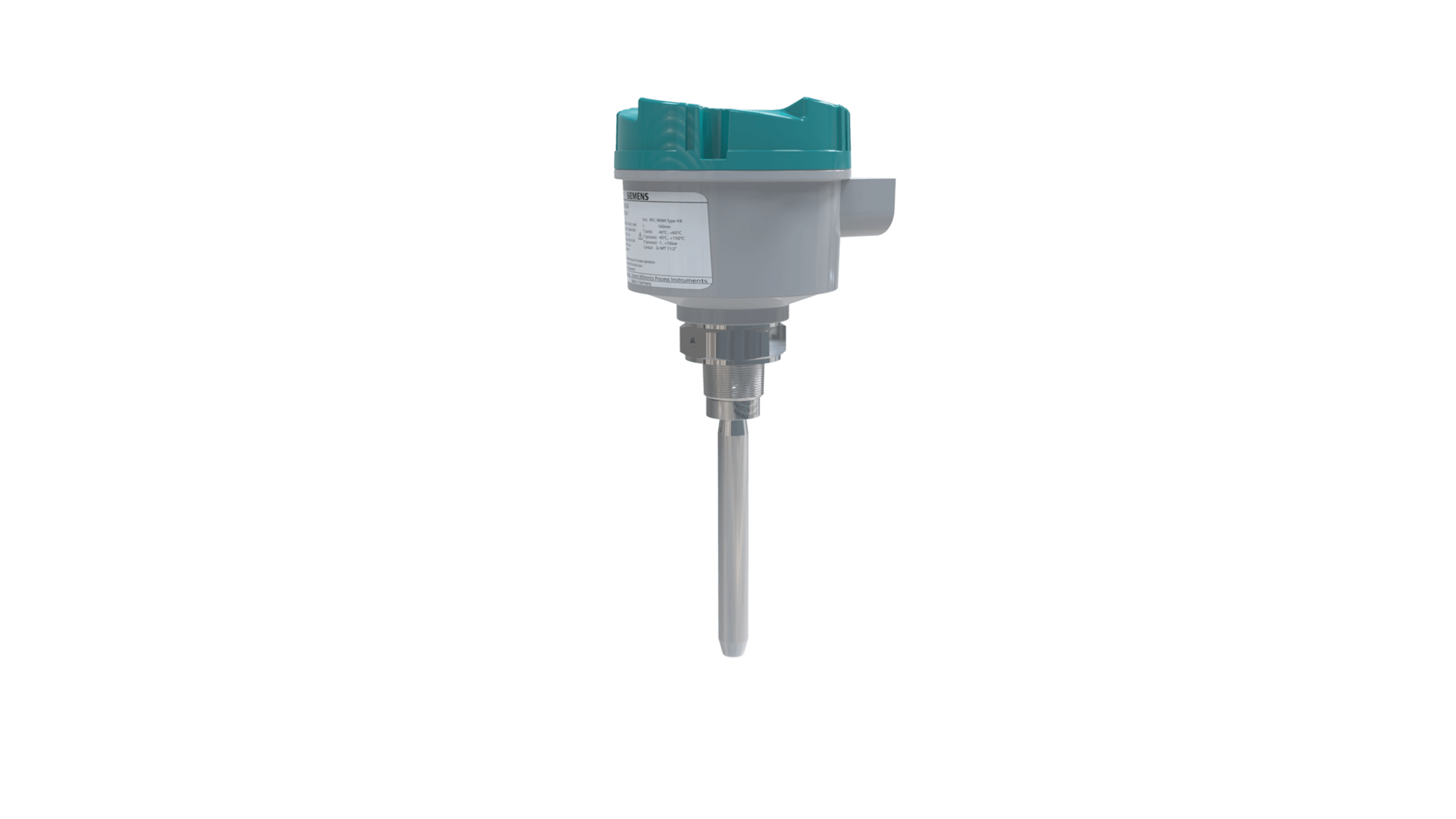

Dry run protection

- SITRANS LVL100

- Very compact for confined space

- Easy installation

- Fault monitoring for corrosion, loss of vibration, and line break to piezo drive

Liquified gas

- SITRANS LVL200

- Low density of 0.5 g/cm3

- Large temperatures variations between -40°C to 30°C (-40 to 86°F)

- Fail safe and SIL2 certified

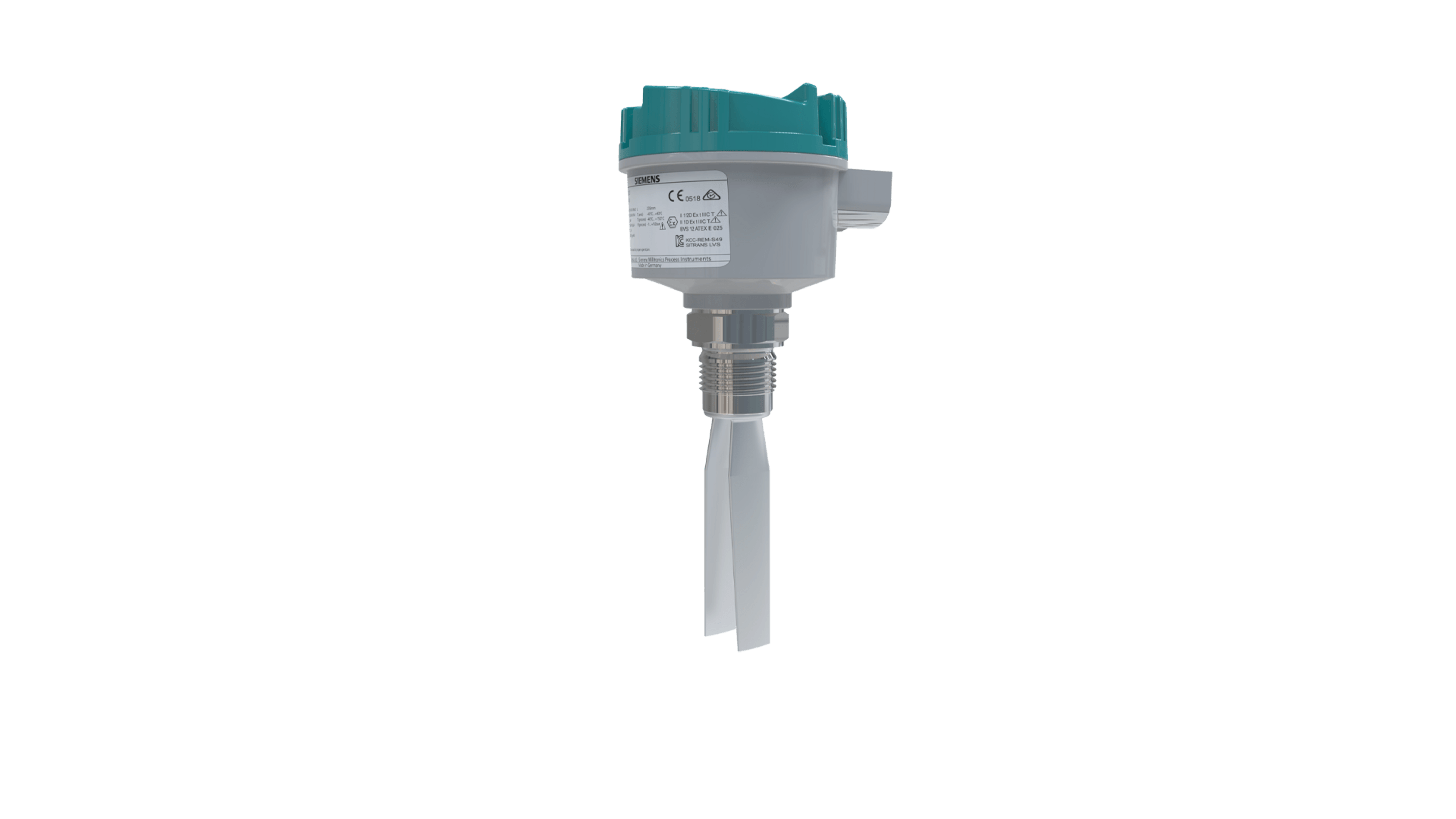

Sludge detection

- SITRANS LVS200 interface version

- Detection of sludge accumulation within water

- Fault monitoring for corrosion, loss of vibration, and line break to piezo drive

- Bulk density of solids > 50 g/l

Mining and aggregate

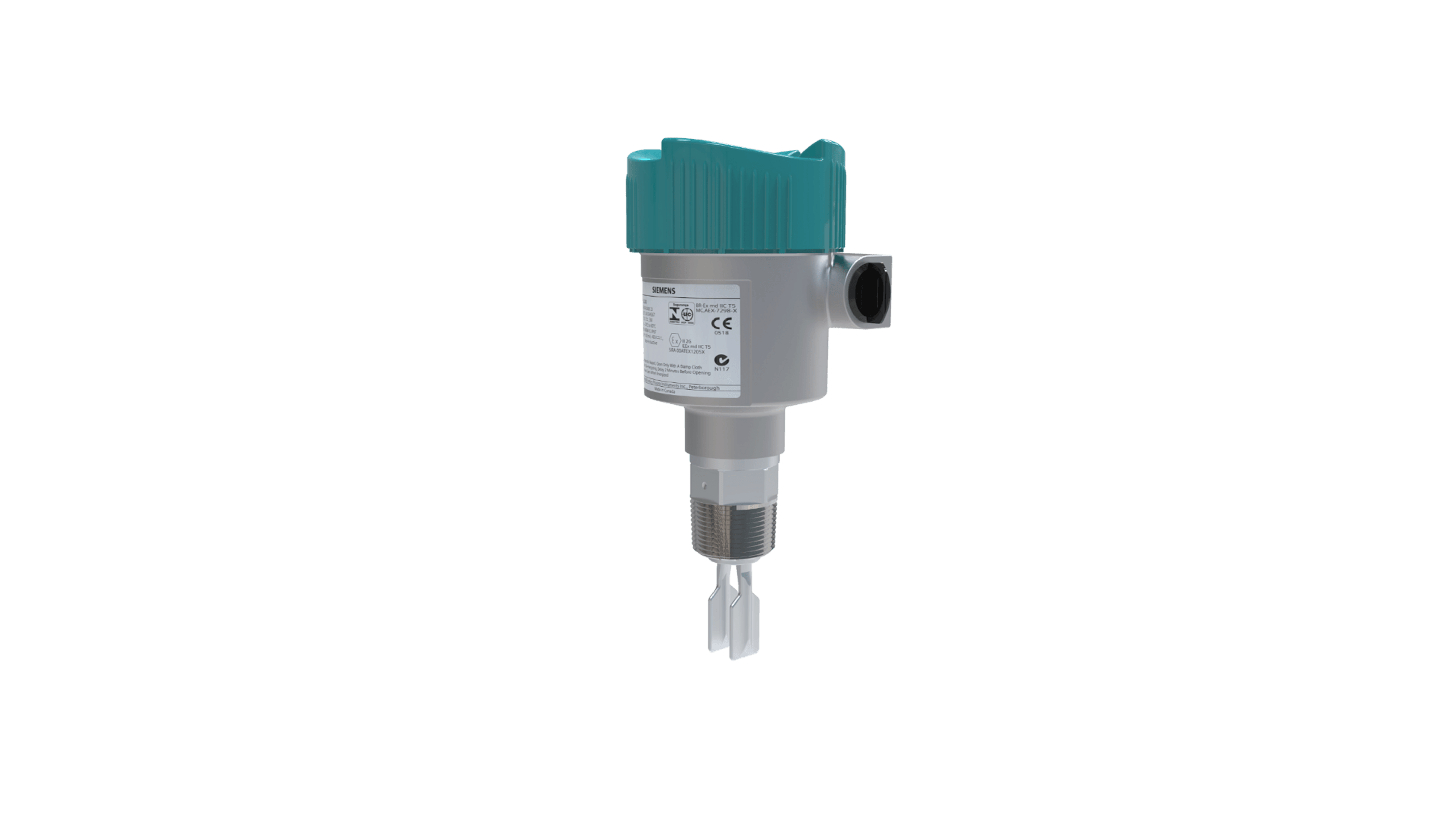

- SITRANS LVS300

- Plug chute detection

- Vibrating rod design prevents false alarms due to bridging materials

- Durable design to with stand harsh environment

The SITRANS LVS and LVL Range

SITRANS LVS and LVL Technical Comparison

SITRANS LVL100 | SITRANS LVL200 | SITRANS LVS100 | SITRANS LVS200 | SITRANS LVS300 | |

|---|---|---|---|---|---|

Range | 40 mm (1.5″) insertion | 40 mm to 4000 mm (1.57″ to 13 ft) | 170 mm to 4 m (6.7″ to 13 ft) | Rigid extension: 165 mm to 4 m (6.5″ to 13 ft) Cable extension: 700 mm to 20 m (27.5″ to 65 ft) | Extensions 160 mm to 4 m (6.3” to 13 ft) |

Process Temperature | -40 to 150 °C (-40 to 302 °F) | -196 to 450 °C (-321 to 842 °F) | -40 to 150 °C (-40 to 302 °F) | -40 to 150 °C (-40 to 302 °F) | -40 to 150 °C (-40 to 302 °F) |

Process Pressure | -1 to 64 bar g (-14.5 to 928 psi g | -1 to 160 bar (-14.5 to 2320 psig) | Up to 10 bar g (145 psi g) | Up to 10 bar g (145 psi g) | Pressure vessel: Maximum 16 bar g (232 psi g) |

Versions Available | Compact | Compact, rod, and high temperature | Compact, rod | Compact, liquids/solids interface, rod and cable | Compact, and rod |

Outputs | Transistor, contactless | Relay, NAMUR, transistor, 8/16 mA, contactless | DPDT relay | Relay or DC PNP, 8/16 mA or 4-20 mA, and NAMUR | Relay DPDT or DC PNP |

Options | Hygienic and marine approvals | SIL 2, hygienic, and marine approvals Extreme pressures and temperatures options Remote testing | – | Detection of solids within liquid

30 bar pressure Stainless steel 316L Universal power supply | Stainless steel 316L Universal power supply |

Key Applications | For use in liquids and slurries, for point level measurement, overfill, and dry run protection in chemical, oil and gas, pharmaceutical, food and beverage, and general industries | For use in liquids and slurries, for point level measurement, overfill, and dry run protection in chemical, oil and gas, pharmaceutical, food and beverage, and general industries | Dry bulk solids in bins, silos, hoppers or settled solids in the mining, cement, food, power, plastics, or general industries | Dry bulk solids in bins, silos, hoppers or settled solids within liquids (interface version) in the mining, cement, food, power, plastics, or general industries | Point level, plugged chute detection, or backup in vessels or hoppers in the mining, cement, food, power, plastics, or general industries |

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham is a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.