A new chapter in the world of Coriolis flow measurement.

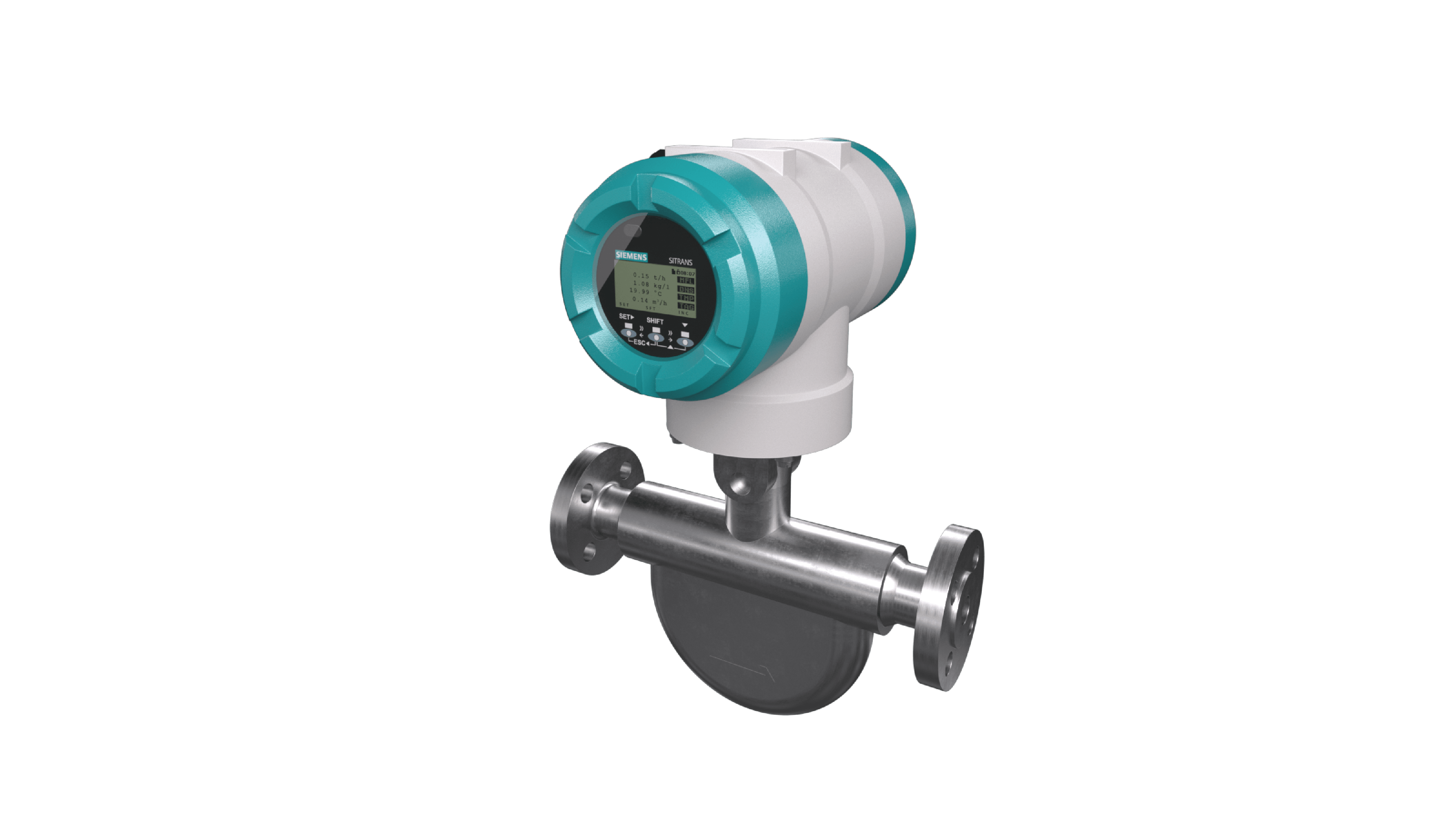

SITRANS FC Coriolis Flowmeters

Designed for high-accuracy mass flow measurement with a low cost of ownership, SITRANS FC Coriolis flowmeters are ideal for demanding liquid and gas processes in every industry – from the smallest dose of chemicals to the massive quanities of bunker fuel pumped into a cargo ship.

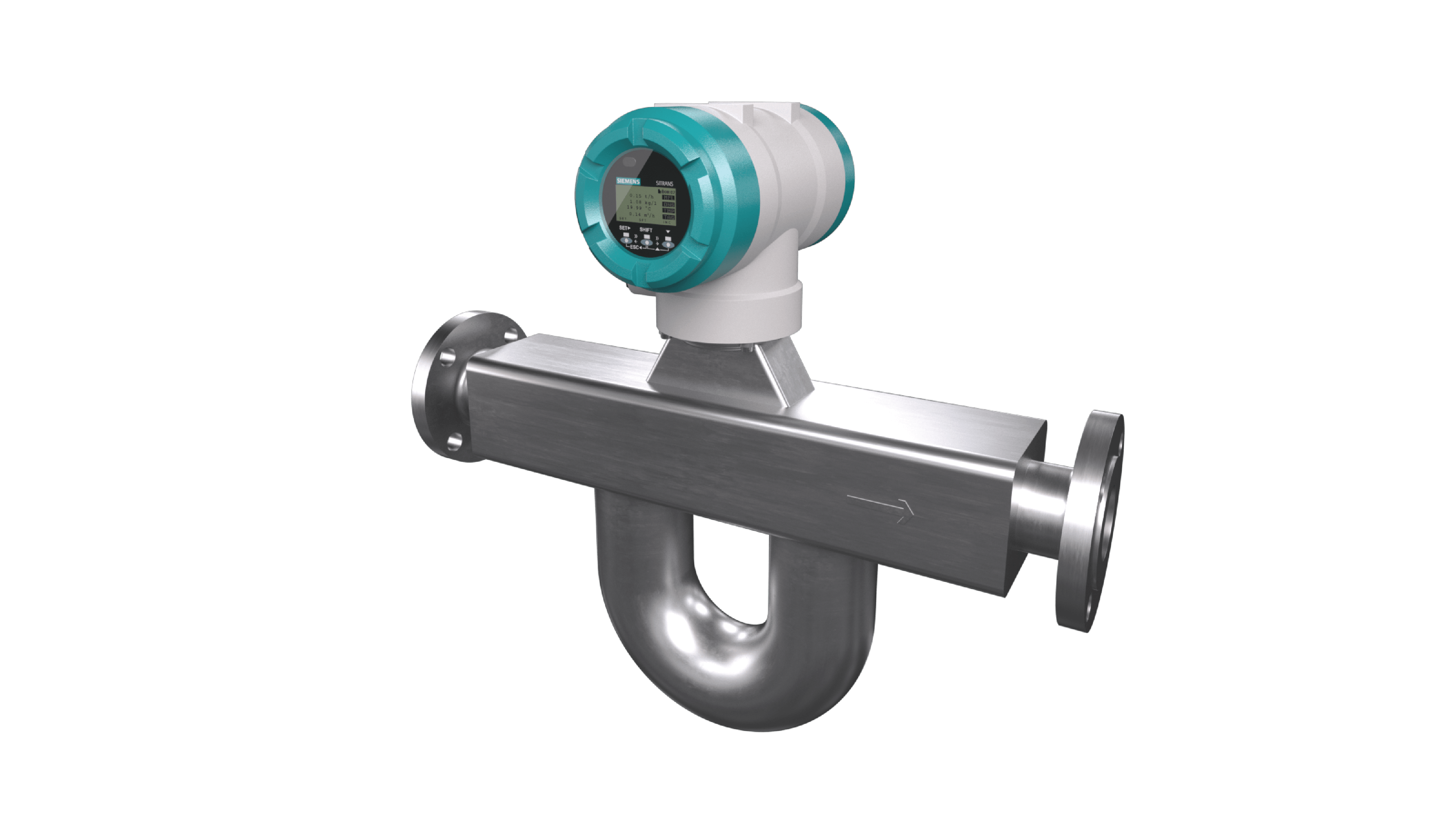

How does a Coriolis flowmeter work?

The Coriolis effect is a driving force behind the exceptional performance of SITRANS FC flowmeters.

Two symmetrical metal tubes are set vibrating. This is ensured by a driver coil in the central section. The oscillation is measured precisely by two pickups – at the inlet and outlet sections. If liquids or gases now flow through the tubes, a phase shift occurs – as with a water hose. The pickups measure the spatial and temporal displacement. This determines the amount of liquid or gas flowing through the tubes.

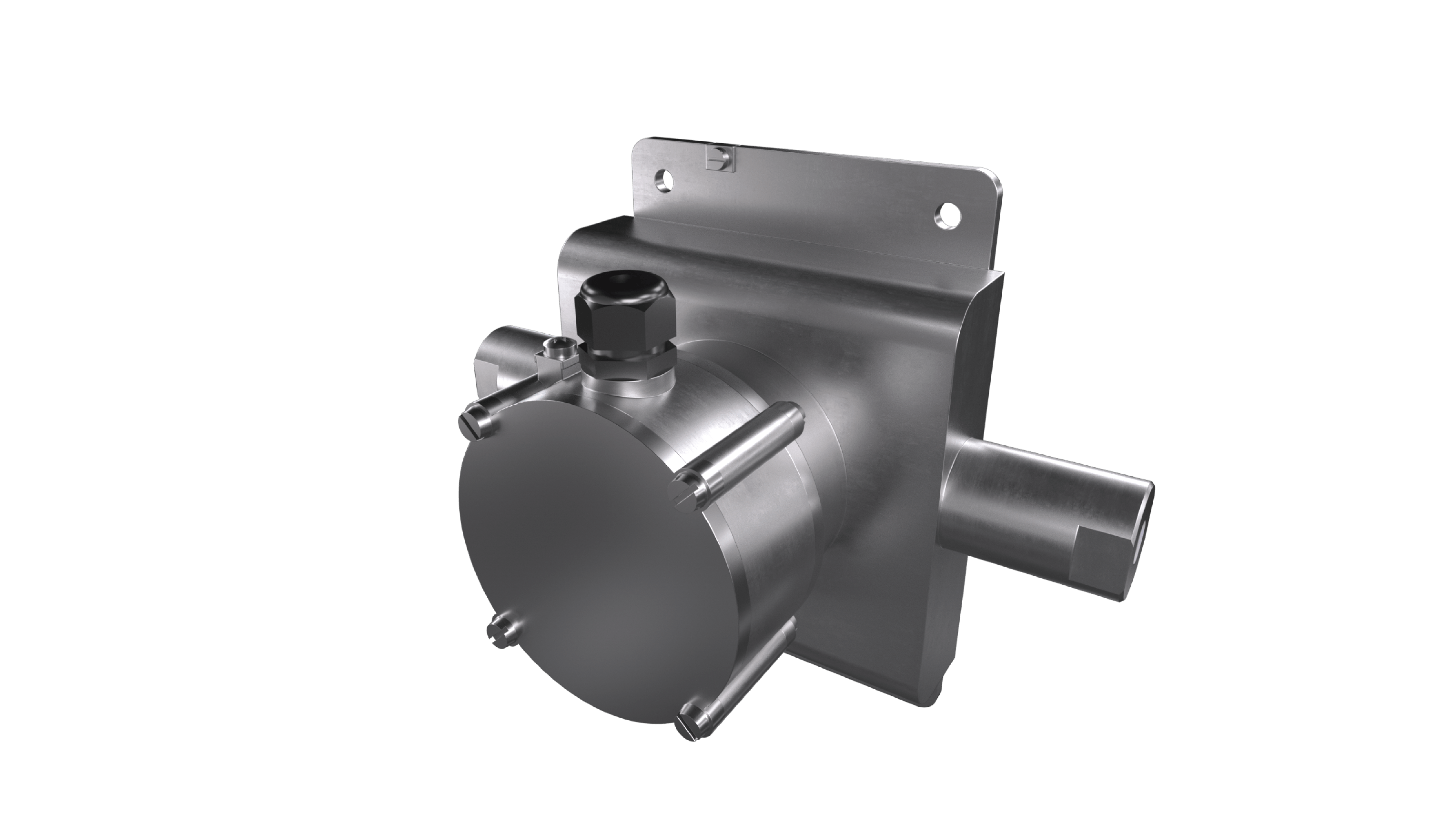

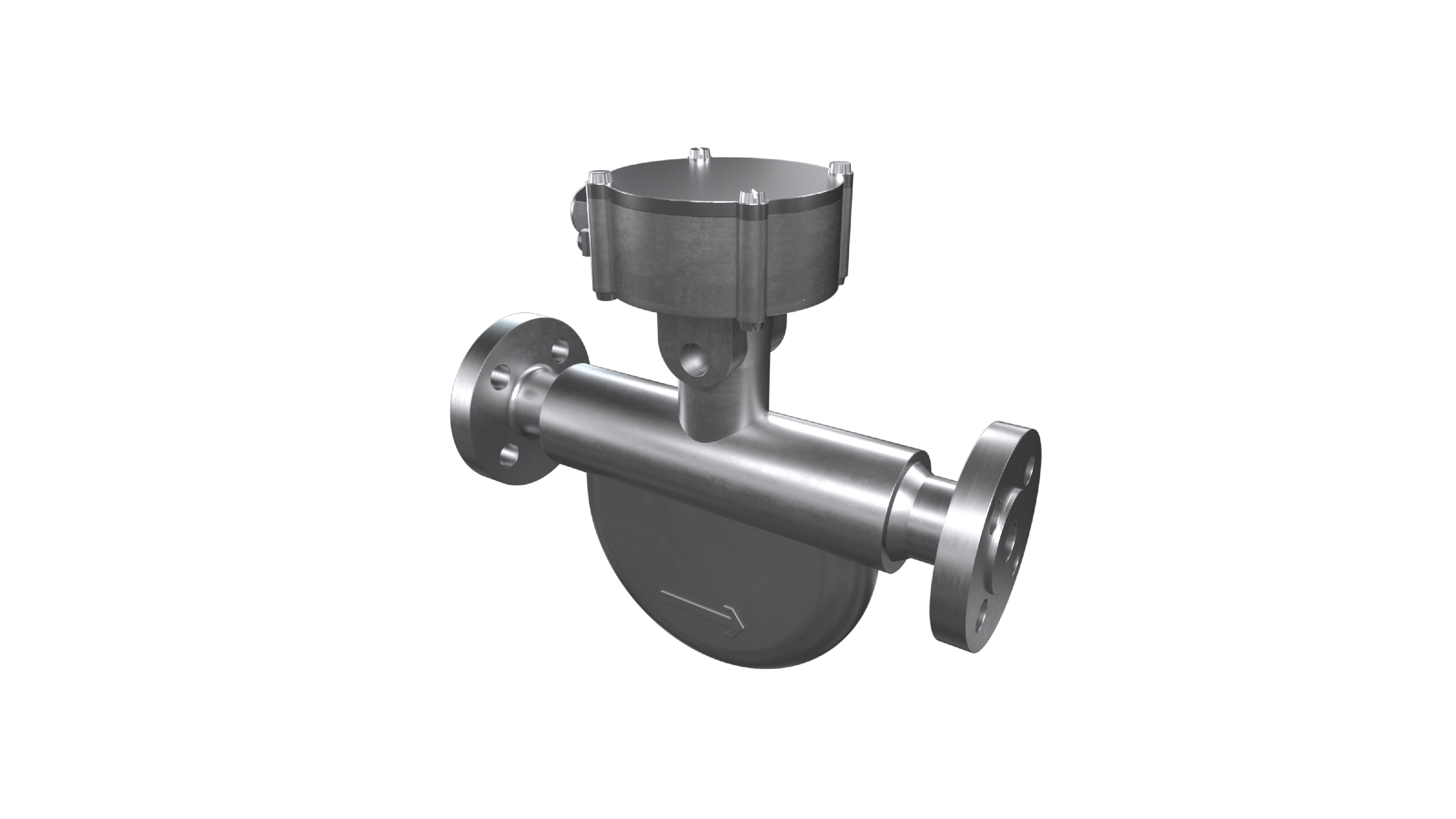

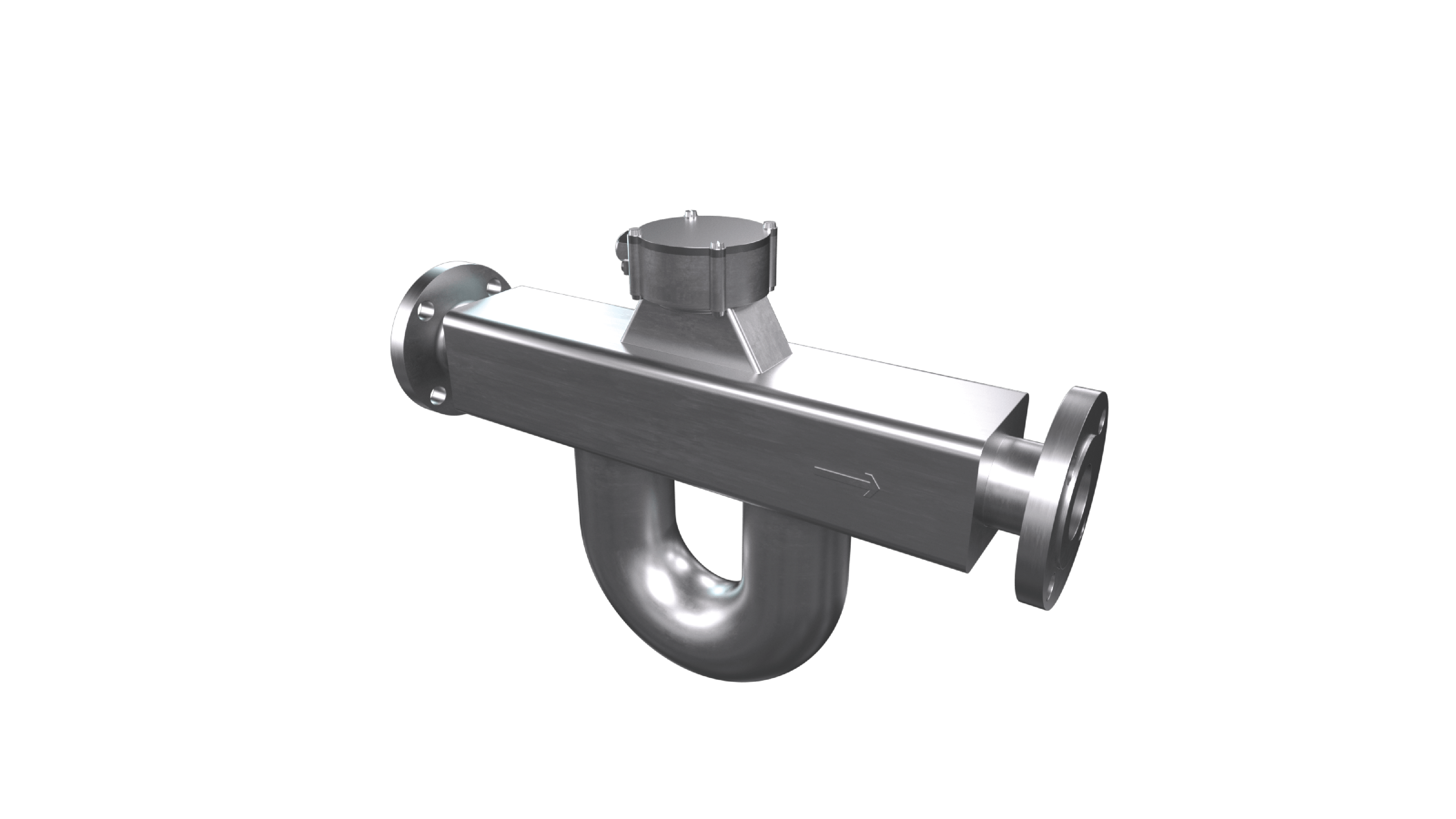

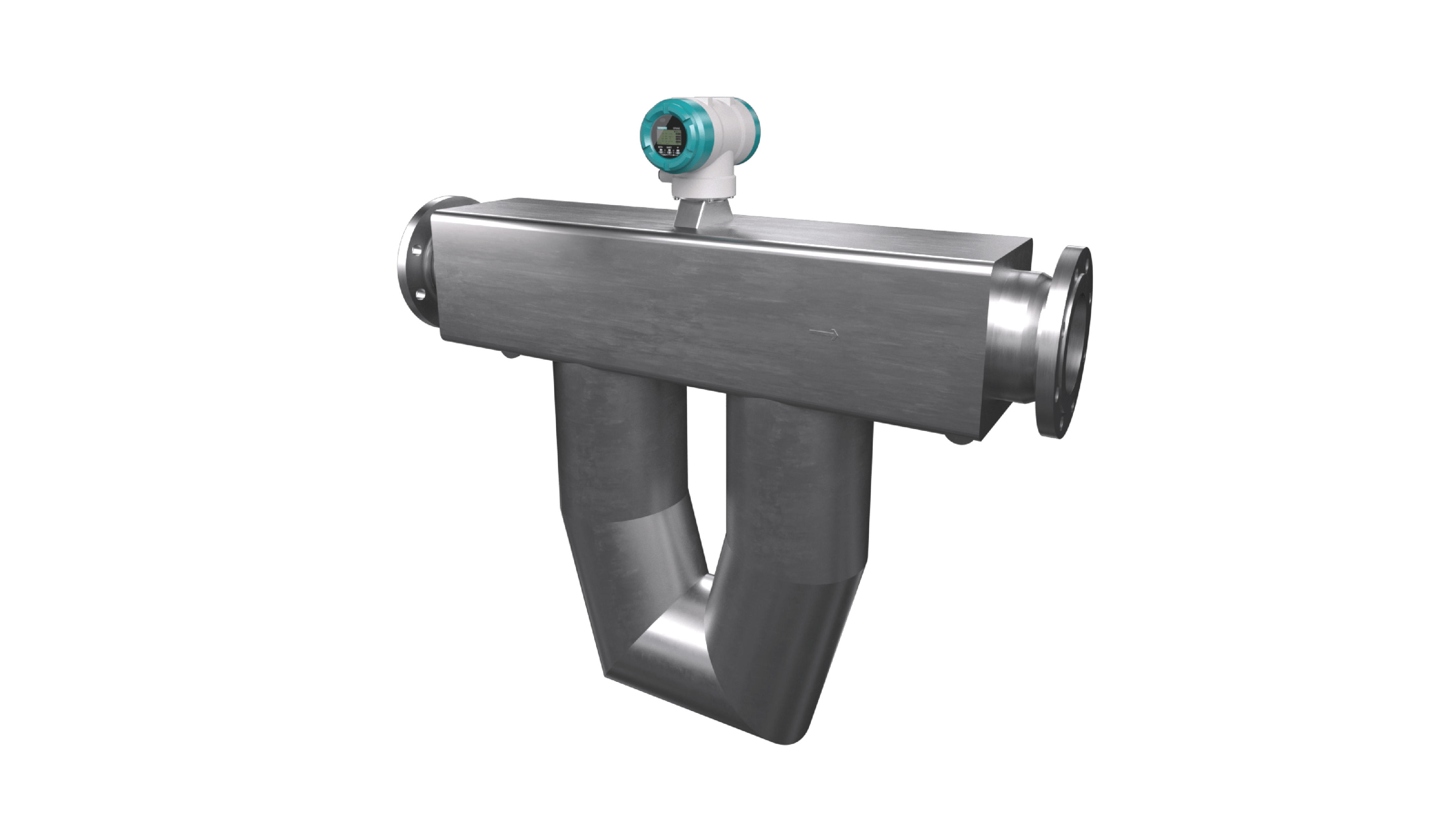

Sensors

Transmitters

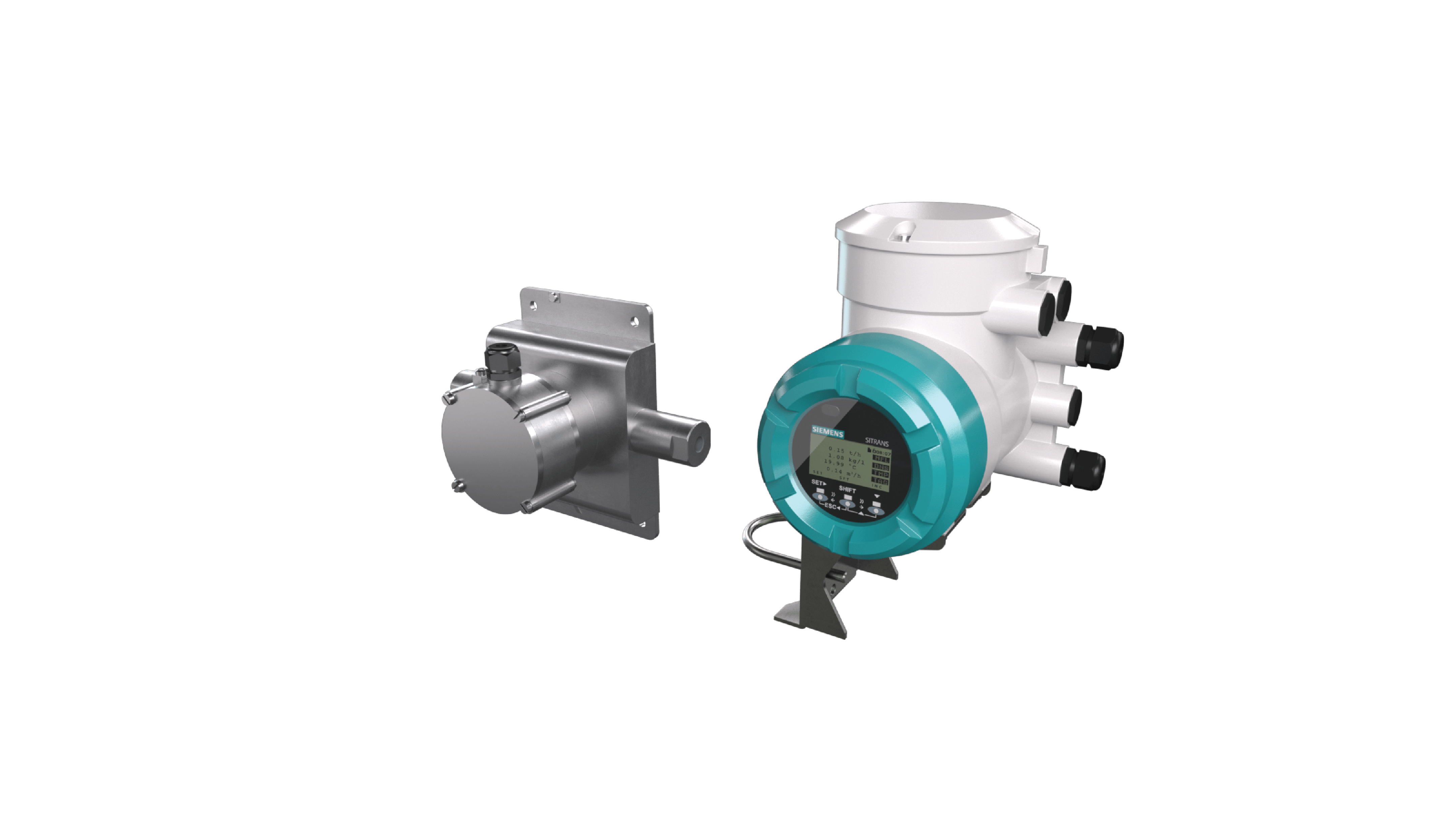

Flowmeter Systems

The SITRANS FC Coriolis Advantage

- Choose your sensor based on your applications need and afterwards select the transmitter model based on the communication and performance requested.

- The modular concept allows to find the right fit for your need.

- Maximum accuracy due to calibration facility accredited according to ISO/IEC 17025

- Tube health check (diagnostic verification) alerts of potential performance issues doe to process events, e.g. unwanted gas or vapor breakout & solid deposits building up in the tubes.

- High measurement sensitivity & intelligent dynamic range keeps the measurement active even in demanding high damping cases.

- Precise flow rate measurement of fluids and gases, multi-phase fluids and fluids with specific gas content using the Coriolis principle.

SITRANS FC Coriolis Comparison

FC120/140 | FC520/540 | FC620/640 | FC720/740 | |

|---|---|---|---|---|

Measuring range | 0.01 – 1500 kg/h | 0.8 – 255000 kg/h | 1.5 – 170000 kg/h | 125 – 1100000 kg/h

|

Maximum process temp. | -50 to +260 °C -58 to +500 °F | -70 to +200 °C -94 to +392 °F | -196 to +350 °C -321 to +662 °F | -70 to +350 °C -94 to +662 °F |

Wetted materials | Alloy 22/2.4602 and

316L/1.4404

| 316L SS/1.4404 | 316L SS/1.4404 or

Alloy 22/2.4602 | 316L SS/1.4404 or

Alloy 22/2.4602 |

Sensor size | DN1 – DN8 | DN10 – DN80 | DN15 – DN65 | DN100 – DN200 |

Maximum pressure | Up to 285 bar Up to 4183 psi | Up to 100 bar Up to 1450 psi | Up to 700 bar Up to 10000 psi | Up to 100 bar Up to 1450 psi |

Approvals | ||||

– Ex-approvals | ATEX IECEx FM Korea Ex | ATEX IECEx FM Korea Ex | ATEX IECEx FM Korea Ex | ATEX IECEx FM Korea Ex |

– Hygienic | 3A EHEDG | 3A EHEDG | ||

– Marine (class 2 and 3) | Det Norske Veritas Lloyds Register Bureaux Veritas American Bureaux of Shipping Korean Register | Det Norske Veritas Lloyds Register Bureaux Veritas American Bureaux of Shipping Korean Register | Det Norske Veritas Lloyds Register Bureaux Veritas American Bureaux of Shipping Korean Register | Det Norske Veritas Lloyds Register Bureaux Veritas American Bureaux of Shipping Korean Register |

Features | Functional Safety SIL2/3 Custody Transfer (NTEP) Namur NE 21, NE 95 Tube Health Check | Functional Safety SIL2/3 Custody Transfer (NTEP) Namur NE 21, NE 95 Tube Health Check | Functional Safety SIL2/3 Custody Transfer (NTEP) Namur NE 21, NE 95 Tube Health Check | Functional Safety SIL2/3 Custody Transfer (NTEP) Namur NE 21, NE 95 Tube Health Check |

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham is a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.