Process Device Manager

Plant Device Management (PDM): Easy maintenance and servicing

Seamless condition monitoring of plant components is an important factor for optimized operation of process plants. With SIMATIC Plant Device Management (PDM), you can seamlessly integrate diagnosis information from intelligent field devices into the control or maintenance system. Benefit from smart management and improve the availability of your plant through preventive maintenance.

Intelligent management of process components

SIMATIC PDM simplifies the parameterization, commissioning, diagnosis, and service of intelligent field devices: From engineering to process control and monitoring, to maintenance of field devices – our aligned product portfolio ensures that your plant is operated with maximum availability and efficiency throughout the entire lifecycle. To ensures a more transparent, efficient, and sustainable plant operation, the device-specific information can be made available to asset management systems or cloud-based condition monitoring systems for further analysis.

Plant Device Management - One heart, many faces...

Our process device management can be used in a variety of ways. No matter how you use our system, the core of every application is SIMATIC PDM (Plant Device Management). In a single software environment, a large number of field devices from well over 200 manufacturers can be uniformly parameterized, diagnosed and managed. Further highlights:

- Since the communication architecture in the field is often heterogeneous, SIMATIC PDM supports all common communication types and network transitions between bus systems, e.g. Ethernet, PROFINET, PROFIBUS DP/PA, HART.

- Data is collected and forwarded cyclically and can also be integrated into cloud-based analysis and processing concepts.

- Devices not yet directly supported can be integrated at any time by importing their device descriptions (EDD) or device description packages (FDI).

- Benefit from future-proof products which are continuously further developed on the basis of NAMUR recommendations NE105, 107 and 129.

Engineering and Commissioning

Many integrated functions of SIMATIC PDM help with effective engineering and shorten commissioning times. For example, thanks to device-neutral project engineering or the support of various device management scenarios. Several views of the project and the devices to be processed are available to the user: Network or plant view, the hardware project view and the parameter view. The Lifelist is the ideal working environment for service and commissioning. Another highlight of SIMATIC PDM is the bulk operation function. This can be used to create work lists for many field devices that SIMATIC PDM processes independently and partially in parallel. Uniform tasks or work steps can also be applied to several field devices simultaneously.

Monitoring & Service of Intelligent Field Devices

SIMATIC PDM Maintenance Station is the first choice when it comes to condition monitoring and maintenance of smart field devices. As a service and diagnostic tool in a stand-alone version, it is independent of process control and automation technology. SIMATIC PDM Maintenance Station can be connected directly to the system bus for device data acquisition, parameterization and management.

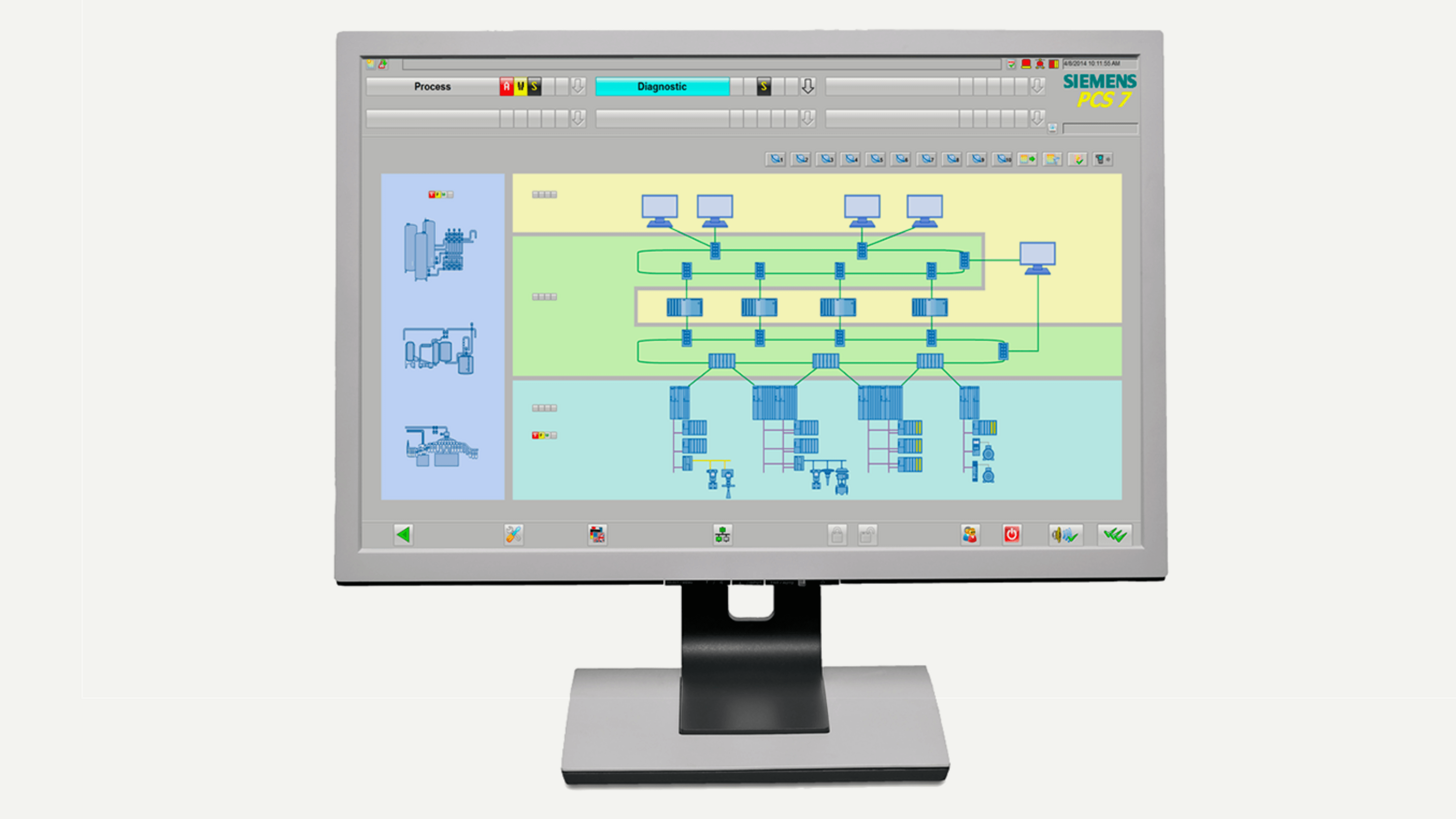

Monitoring & Service Module for SIMATIC PCS 7

The SIMATIC PCS 7 Maintenance Station is responsible for the diagnosis, component management, acquisition and forwarding of parameterization, diagnostic and status data of components within a SIMATIC PCS 7 project. The station creates the basis for effective maintenance and repair strategies. Within the SIMATIC PCS 7 Maintenance Station, SIMATIC PDM is used to record identity data, detailed diagnostic information, parameterization and status data.

Key Benefits

Uniform display of diagnosis and maintenance status throughout the plant - including mechanical assets

Increased plant availability and minimized total cost of ownership by continuously monitoring the parameter and status data of field devices

Minimized training effort thanks to uniform operation and harmonized functions for engineering, operations and service

Support of international standards for the integration of field devices and fully embedded in SIMATIC PCS 7

Build innovative machines faster without costly prototyping with Efficient Motion Control.

With Effective Motion Control, machine builders can easily overcome major challenges and enable faster time-to-market, increased functionality, resolve complex system requirements, and demands for safety and sustainability.

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham is a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.