RTLS

SIMATIC RTLS allows the realization of locating tasks that demand a high level of precision over large areas, both indoors and outdoors. The system is suitable for locating and detecting large populations of relevant objects. Each object receives a unique ID by means of a transponder, which is attached to manufactured items, containers, transport units or people. It is also possible to display freely definable information on the transponder.

Overview

As a leading global supplier of real-time wireless location systems, Siemens offers a uniquely integrated and scalable portfolio with SIMATIC RTLS. SIMATIC RTLS is the locating system for flexible and cost-effective locating solutions.

Using SIMATIC RTLS, material flows can be navigated, mobile robots controlled, the use of components monitored and the assembly of the end product documented in full. This makes SIMATIC RTLS an essential component of the digital infrastructure of the factory of tomorrow.

SIMATIC RTLS allows the realization of locating tasks that demand a high level of precision over large areas, both indoors and outdoors. The system is suitable for locating and detecting large populations of relevant objects. Each object receives a unique ID by means of a transponder, which is attached to manufactured items, containers, transport units or people. It is also possible to display freely definable information on the transponder.

Various active transponders are available for industrial applications. They are designed to have a long service life and are operated via exchangeable batteries, rechargeable batteries or an external power supply.

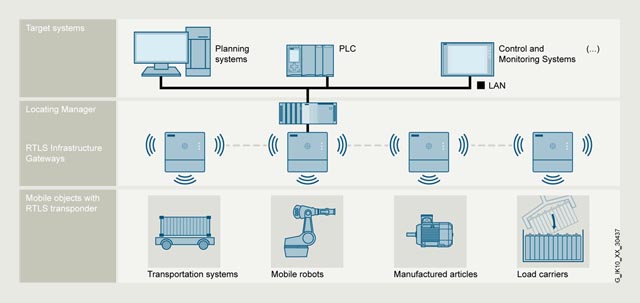

SIMATIC RTLS locating platform complete solutions comprise three elements:

- Active transponders which are attached to the objects to be located

- Locating infrastructure consisting of gateways which record transponder signals and forward them to the locating server

- The SIMATIC Locating Manager locating server, which calculates the real-time positions of the individual transponders and forwards them to higher-level systems

This kind of system solution can be scaled in size at any time. Easy-to-install devices in combination with a license-based locating server enable the expansion of existing locating infrastructure with additional applications, or extension of the area to be localized. An ISO standard interface is available for integration in the IT system landscape, for example.

Within SIMATIC RTLS, there are product families that are optimized to different applications. The main difference lies in the wireless technologies used for communication and locating processes, which are tailored to the specific application. The products within a specific product group are compatible with one another, while products from different product groups cannot be combined with one another.

Benefits

Flexible and Scalable

- Unique hybrid technology enables flexible adaptation to suit customer requirements

- Can be expanded to new applications and operating areas as desired

- Flexible and cost-effective solutions due to scalable complete portfolio in the area of industrial locating

Precise and Reliable

- Real-time locating, accurate down to the centimeter

- Developed for demanding industrial environments

Simple

- High-performance Locating Manager for commissioning and optimizing the locating infrastructure

- Versatile integration in the IT system landscape through ISO standard interfaces

Comprehensive

- Worldwide support for problem-free implementation of solutions

SIMATIC RTLS significantly increases the quality of data acquisition in production control and logistics. As well as the identification of objects and vehicles, position data is also available in real time. The locating platform covers entire buildings, halls and factory sites almost without gaps and ensures a degree of transparency previously unknown with established technology.

This results in competitive advantages for customers, such as increased productivity, reduced costs and shorter process times. The SIMATIC RTLS locating platform offers a broad product portfolio so that the optimum solution for the customer can always be realized. The unique hybrid technology enables perfect adjustment to the application and, at the same time, enables co-existence with other wireless technologies. The powerful SIMATIC Locating Manager can process a very high number of transponders in real time.

There are multiple applications for SIMATIC RTLS in industrial automation. Objects of almost all types, e.g. workpiece holders, tools and forklifts, can be located and tracked in real time for both production and material handling control. Logistical processes in particular benefit from the high quality and availability of location information. The management of vehicle fleets, such as buses and trams in public transport systems, but also trucks and forklifts in production and logistics environments, is made possible by dedicated product groups within SIMATIC RTLS. By making high-quality location information available in real time, the locating platform can support processes from integrity monitoring, through transmission of status data from the vehicles, all the way to automated loading, cleaning and maintenance procedures.

Integration

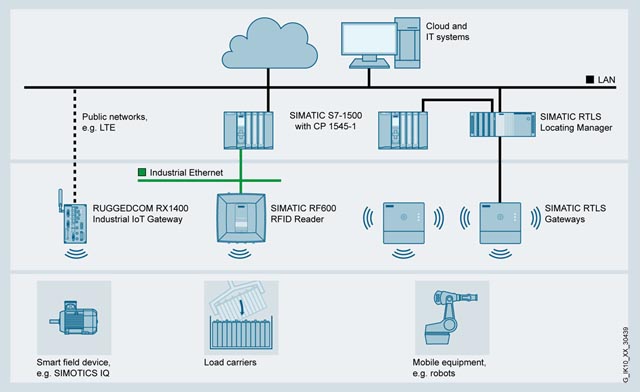

Easy integration in the automation level

With our SIMATIC RTLS portfolio, you can always find the right solution. Simple integration of SIMATIC RTLS in the IT landscape is achieved with the SIMATIC Locating Manager software. This ensures that you have an integrated software architecture and saves considerable time and costs during engineering, commissioning and maintenance.

A broad range of software functions (e.g. locating service, network management, 2D view) enables fast and safe commissioning, as well as integration in the application.

Production Control

Many innovative companies are thinking about how they can make their traditional workflows in production and logistics more dynamic in order to allow them to respond to market changes faster, perfect utilization or produce smaller batch sizes.

Flexible, self-organizing production and logistics concepts, based on our SIMATIC RTLS locating platform, are key here. After all, versatility in the control of products outside track-bound lines needs first-class locating to work. SIMATIC RTLS masters the requirements posed by increased product diversity in very tight spaces throughout the manufacturing process. This enables reliable, efficient and cost-effective make-to-order production.

Asset Management

Assets such as tools, equipment and containers are crucial for production and logistics. Industrial locating of e-ink transponders ensures they are used efficiently. Inventory can be recorded in real time and the corresponding status determined with precision. In this way, the utilization of assets can be accurately monitored at all times and refined to suit inventory quantities, loads and maintenance in a targeted manner. And best of all: The current status of the asset is permanently shown on the display of the e-paper transponder in readable form. Time-consuming printing of barcode labels for the asset is therefore no longer necessary.

Supply Chain Management

Competitive production on an industrial scale relies on global supply chains of individual parts and components. With industrial locating, these supply chains become transparent and predictable, and can be planned to maximum advantage. This means that supply bottlenecks and downtimes can be avoided, inventory can be optimized and profit margins improved.

Build innovative machines faster without costly prototyping with Efficient Motion Control.

With Effective Motion Control, machine builders can easily overcome major challenges and enable faster time-to-market, increased functionality, resolve complex system requirements, and demands for safety and sustainability.

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham is a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.