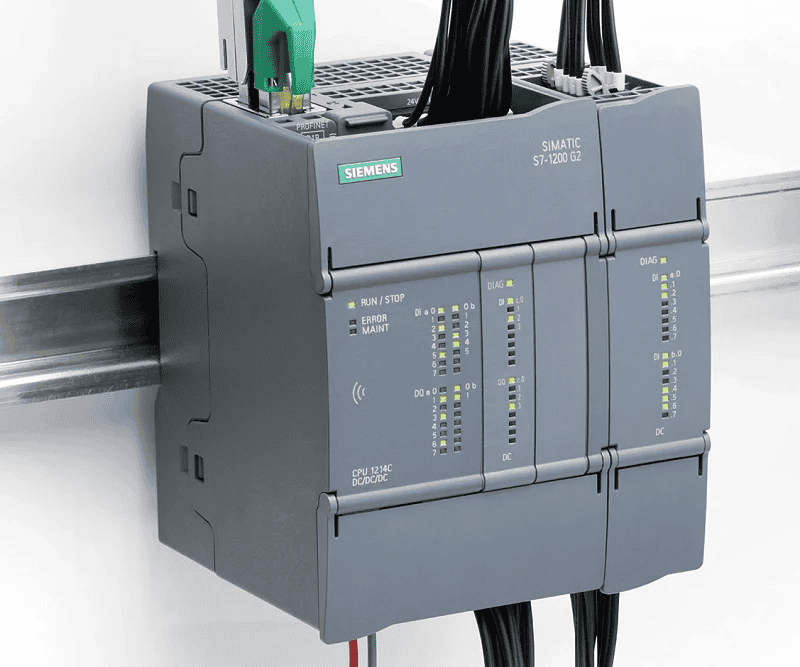

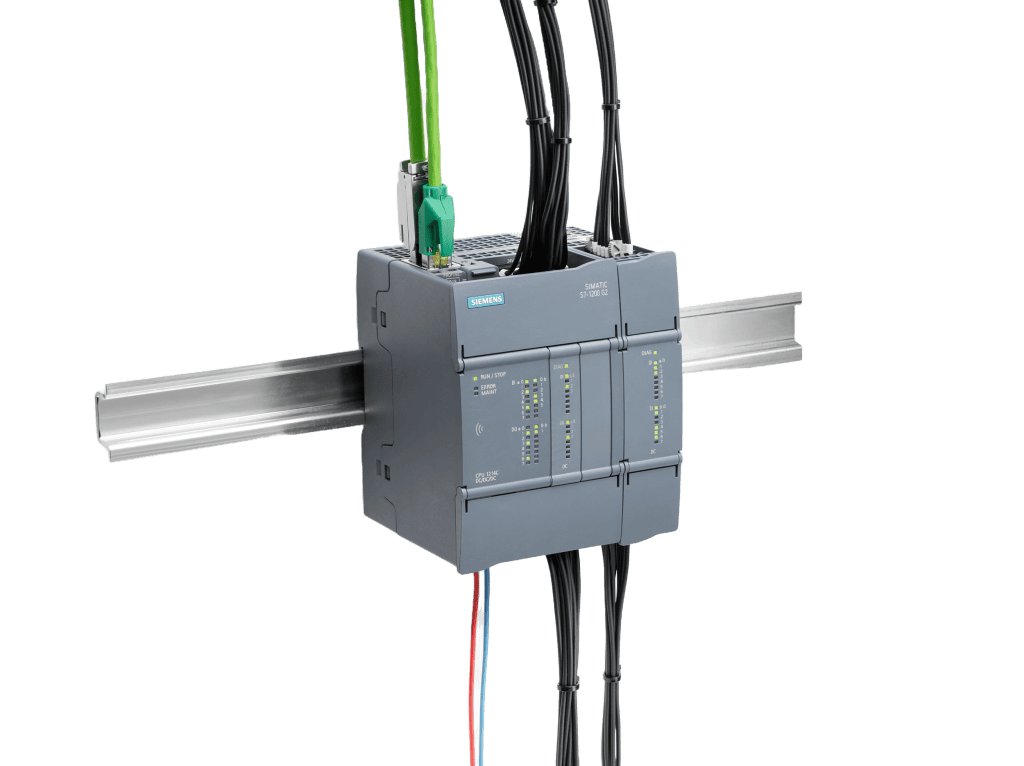

SIMATIC S7-1200 G2

Bringing new standards in the field of basic automation controllers.

SIMATIC S7-1200 G2 sets new standards for simple but high-precision automation controllers. The new controller family enables the combination of integrated motion control functionalities with space-saving and flexible machine safety solutions. In addition, SIMATIC S7-1200 G2 offers entry into seamlessly scalable customer applications while meeting modern performance requirements for cost-effective basic automation solutions.

The SIMATIC S7-1200 G2 is available to order now!

AVAILABLE FOR PURCHASE!

Overview

SIMATIC S7-1200 G2 configured in the TIA Portal fits perfectly

Modular space-saving controller for automation systems requiring simple or extended functionality in the area of logic, HMI and networking.

- Perfect for stand-alone and interconnected machines as well as cost-effective automation solutions.

- Enabling more flexible, scalable, and higher-performance motion control demands.

- Increasing operational performance and reliability with smart automation solutions and fail-safe integration.

- Simple integration into interconnected systems and into systems that require one or more HMI devices.

- Extended functionality for small motion control systems and small process applications.

- Two communication ports on each CPU.

Controller, HMI and Networking

Everything developed in one software architecture

Industry challenges

The solution to increasing demand for smart automation solutions.

The advancement of technology is placing greater pressure on industry and machine building. Not only are high-end applications impacted, but there is also a growing demand for cutting-edge technology to enhance productivity in simpler automation solutions. This requires a well-coordinated automation system that minimises complexity and is optimised for cost efficiency over the entire life cycle.

Challenges and opportunities

Technological advancements require constant improvements and state-of-the-art technology.

Legal regulations (such as machine safety) must be met without driving up costs or compromising productivity.

Versatile customer requirements demand scalable and flexible automation solutions.

Globalisation

- Global service network

- Worldwide availability of products

Digitalisation

- Extensive standardisation opportunities

- Cloud connectivity

- Optimisation, transparency through data analyses

Protection of human and machines

- Integrated safety and leading-the-way security functions

Smart handling

- Easy installation, wiring, and fast, efficient commissioning

- Efficient engineering

Increased production output

- High communication performance, fast system response and efficient data processing

Factory availability

- Fast error localisation and elimination to reduce downtime

- High spare part compatibility and availability

Key Features

New standards in the field of basic automation controllers.

The SIMATIC S7-1200 G2 sets new standards for simple but high-precision automation controllers. The new controller family enables the combination of integrated motion control functionalities with space-saving and flexible machine safety solutions. In addition, the SIMATIC S7-1200 G2 offers the entry into seamless scalable customer applications while meeting modern performance requirements for cost-effective basic automation solutions.

High productivity

Delivering beneficial outcomes with efficient motion control and flexible machine safety solution.

Seamless scalability

Offering scalable, flexible and state-of-the-art technology with increased performance across all innovated SIMATIC controllers.

Cost optimisation

Offering scalable, flexible and state-of-the-art technology with increased performance across all innovated SIMATIC controllers.

Easier fail-safe accessibility

Flexible expansion of fail-safe I/Os according to the required number of safety functions and safety modes with an optimised fail-safe hardware portfolio (e.g., fail-safe signal boards).

- Integrated in the complete range

- Improved F-IO Portfolio

- Integrated in STEP 7 Basic

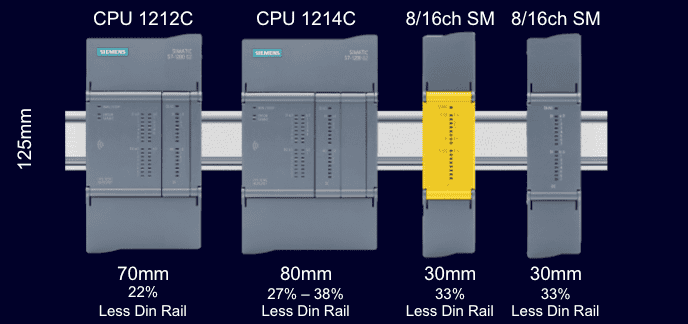

More competitive solutions with increased flexibility and scalability, and new design

Flexible adaptation to a wide range of customer requirements thanks to an optimised hardware portfolio and seamless scalability across the SIMATIC controller portfolio.

New Design

- HW: ~25% space reduction

- Fail-safe integrated

- Memory expansion

Integrated motion control

SIMATIC S7-1200 G2 controllers enable the control of single axes, coordinated axes and simple kinematics. The configuration of motion control functions is very simple on the basis of integrated technology objects.

Perfect Integration with

- Kinematics,

- Multi Axis Control

- Single Axis Control

Higher performance and enhanced connectivity

A new level of productivity with improved processing power and dedicated communication performance, as well as NFC- functionality with wireless access to diagnostic, operational and device data.

Enhanced connectivity

- PROFINET:31 devices with IRT

- 8 High-Speed-Counter

- Near Field Communication(NFC) and Ap

New HW Design

Enhanced performance and communication

- Enhanced processing power, dedicated communication performance and more memory

- Up to 31 PROFINET devices and deterministic program execution with PROFINET IRT

- Near Field Communication (NFC)for commissioning and diagnostics support

Easier onboarding entry for fail-safe products

- Fail-safe integrated in the complete range (PROFIsafe communication, I/Os)

- Improved F-I/O portfolio(fail-safe signal boards, fail-safe signal modules with mixed I/Os)

- Fail-safe & Motion Engineering integrated in TIA Portal Basic

For your specific requirements, talk to us.

To see how we can help with your systems or if you have any enquiry, please get in touch – we’ll be pleased to help. Send us an email at support@parmley-graham.co.uk or fill the form below.

Key advantages

Operational performance and reliability

New standards for entry into scalable automation

Addressing the challenges the industry face such as...

- Increasing demand for enhanced performance and functions in basic automation

machines:- Integrated motion control functionality

- More flexible machine safety solutions

- Higher data communication performance and faster cycle time

- High machine life cycle costs, ranging from initial investments to operational and

maintenance expenses - Limitations of a non-scalable system lead to restricted flexibility for individual

customer requirements

Driving a powerful solution to address industry challenges...

- Integrated motion control for basic automation machines to implement a wide

range of automation task - Flexible machine safety implementation with a cost optimised safety portfolio

and multiple operating modes to ensure maximum productivity - Enhanced processing power, dedicated communication performance and more

memory in SIMATIC S7-1200 G2 controllers - Seamless scalability across the entire innovated SIMATIC controller portfolio to

offer the right controller for every automation task

Delivering beneficial outcomes and competitive advantages to the industry

- High performance and productivity: Perfect coordination between standard,

safety and motion control in a single PLC - Cost-optimised across the machine lifecycle: Integrated technology functions,

optimised hardware portfolio and smart engineering solutions - Seamless scalability and state-of-the-art technology across all innovated SIMATIC

controllers, offering flexibility for every automation requirement

The right basic controller for all market challenges...

..and a powerful component for integrated automation solutions.

The SIMATIC S7-1200 G2 is perfectly suitable to integrate in applications and solutions that address challenges in different fields.

Efficient Motion Control

Challenge

Ensuring maximum productivity requires safe, highly automated and coordinated machine operating modes

- High-precision movement of machine components demand synchronised processing of signals

- High complexity in the system architecture and selection of components, as many devices are required to implement IO-connection, drive technology and machine safety

- High level of expertise required in the engineering of motion control solutions

Solution

Simple single axes control up to coordinated axes control and easy kinematics

- Integrated motion control technology objects simplifying system configuration

- PROFINET IRT for fast program execution at synchronised intervals

- Coordinated machine safety and motion control in one single PLC reducing system complexity supported by one common engineering platform (TIA Portal)

- Ready-to-use applications and comprehensive motion control trainings

Business value

- High level of productivity: optimum integration of high-precision motion control and flexible machine safety operations

- Faster time-to-market: fast generation of user programs with less development effort and easily configurable motion profiles using Technology Objects

- Seamless scalability: from compact basic automation machines to high-end applications with many more axes, as the motion control functions are realised identically across all SIMATIC controllers

Flexible Machine Safety

Challenge

- Consideration of different operating modes in terms of operability and thus safety

- Machines of various sizes and complexity with different number of safety functions required

- Need to change safety concept if a certain level of complexity is reached

- Many hardware devices necessary in order to realise safety functions, leading to high wiring effort and complex system architectures

Solution

- Flexible expansion of fail-safe I/Os according to the number of safety functions with up to two fail-safe signal boards or fail-safe signal modules with mixed I/Os

- Fail-safe engineering integrated in STEP 7 Basic (no safety license necessary)

- Flexible machine safety implementation with multiple operating modes (e. g. Safely-Limited-Speed) to ensure maximum productivity

- Safety integrated in SIMATIC S7-1200 G2, together with motion control and standard machine control with the associated communication (PROFIsafe)

Business value

- Highest flexibility: Use of exactly the required hardware and I/Os with the improved signal board and signal module concept

- Cost-efficiency:

- Space savings, cost savings and reduced complexity by expanding the CPU with matching fail-safe I/Os for your safety application

- Safety, Motion and Standard control in a single device enables seamless configuration (engineering), communication and thus highest productivity

- Scalability and standardisation: Easy adaptation to different machine configurations across the whole SIMATIC Controller Portfolio

Machine Performance and Reliability

Challenge

- On-site programming required for adaptation of customer-specific network

settings in the PLC - Additional hardware devices with direct access necessary to extract diagnostic data

- Long machine downtimes in the event of machine failure if efficient diagnostics are not provided

- Availability of diagnostic information usually requires high programming effort

Solution

- Near Field Communication (NFC) functionality of all SIMATIC S7-1200 G2 controllers1

- Access to diagnostic data and previously configured process data for quick and efficient machine service

- Setting IP-addresses and other network settings without programming device during commissioning

Business value

- Shorter downtimes thanks to plain-text diagnostic information about the entire PLC station and quick data access

- NFC functionality eliminates the need for direct access with additional

programming device to the PLC - Significant time savings thanks so simplified handling and configuration

- Increased machine transparency across the machine life cycle

Order the S7-1200 G2:

Don't be the next casualty of industrial cyber attack.

Protect your company and assets, and comply with IEC 62443 and NIS 2 regulations.

The importance of Industrial Cybersecurity is growing as threats increase. Legislators are requiring more and more industries and companies to improve the protection of their businesses and customers – now is the best time to act.

Find out how we can help.

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham is a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.