E-STOP relay for maximum functionality in minimum width

The safety relays PNOZsigma combine many years of experience with today’s very latest safety technology. With the E-STOP relay you can achieve maximum safety and cost-effectiveness with little effort.

With particularly narrow housing widths and diverse functionality packed into each device, the E-STOP relay provides maximum functionality in minimum width. Implement safety technology faster, with greater flexibility and more efficiently, while saving space.

Applications and features of the emergency stop relay

As well as the safe monitoring of E-STOP, safety gates, light barriers, two-hand control devices and time, a range of special applications are also available, such as speed monitoring or safe brake control. Numerous devices are suitable for use in heights of up to 5000 metres. Use PNOZsigma for your application, too!

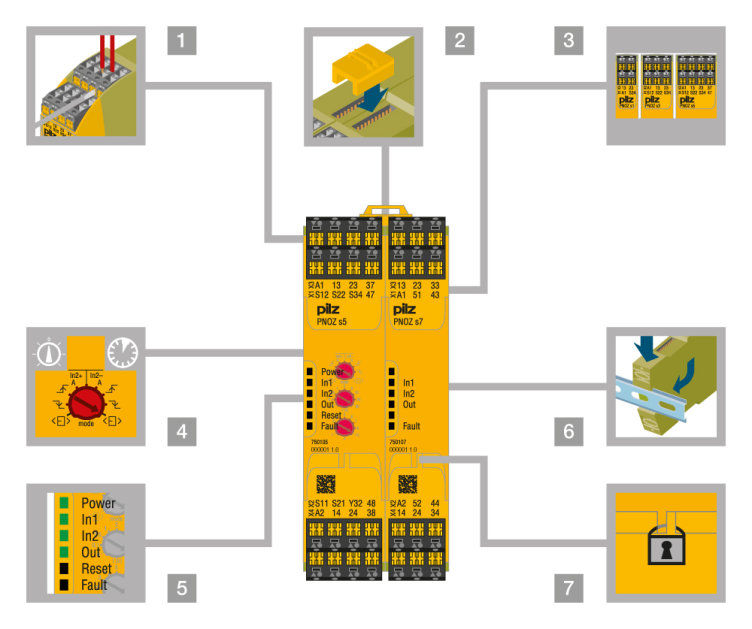

- Rapid installation: with push-in spring terminals

- Wiring work reduced by 20 %: connectors used to expand contacts

- Simple configuration: designation and position of the terminals is the same on all device versions: so connections and devices can always be assigned quickly during configuration, installation and diagnostics

- Maximum flexibility: selectable operating modes and timer functions

- Diagnostics in seconds: via 6 LEDs – no external measuring devices required

- Rapid assembly via spring clips: no need for tools

- Tamper-proof: setting elements have a lockable cover

Applications and features of the emergency stop relay

PNOZsigma safety relays for E-STOP, safety gates, light barriers

| TYPE | PNOZ S1 | PNOZ S2 | PNOZ S3 | PNOZ S4 | PNOZ S4.1 |

|---|---|---|---|---|---|

| E-STOP | |||||

| Safety gate | |||||

| Light curtain | |||||

| Performance level (PL) | c | e | e | e | e |

| Safety integrity level (SIL) CL | 2 | 3 | 3 | 3 | 3 |

| Output contacts (safe) | 2 | 3 | 2 | 3 | 3 |

| Width in mm | 12.5 | 17.5 | 17.5 | 22.5 | 22.5 |

| Special approvals | – | – | – | – | Burner control/ burner management EN 50156-1 |

Build innovative machines faster without costly prototyping with Efficient Motion Control.

With Effective Motion Control, machine builders can easily overcome major challenges and enable faster time-to-market, increased functionality, resolve complex system requirements, and demands for safety and sustainability.