KUKA KMP 600-S diffDrive

KUKA KMP 600-S diffDrive is an AMR platform with differential drive that provides quick and untiring support in logistics, with a payload of up to 600kg and the highest safety standards.

To purchase the KMP 600-S diffDrive or to discuss your specific requirements, please speak with our team.

Overview

Mobile freedom with AGVs: Material transport in dynamic environments

The KUKA Mobile Platform KMP 600-S diffDrive opens up new avenues and provides greater flexibility for production intralogistics. As an automated guided vehicle (AGV) with a payload of up to 600 kilograms, the KMP 600-S diffDrive needs no safety fencing, so it enables maximum freedom of movement for employees. Laser scanners mounted at the front and rear provide maximum safety and allow for high speeds in all directions of travel when cycle times require it.

At up to two meters per second, the KUKA KMP 600-S diffDrive mobile platform offers speedy performance – and uses laser scanners and 3D object detection to meet the highest safety requirements. This automated guided vehicle system takes industrial intralogistics to a new level.

Purchase the KMP 600-S diffDrive now. Please speak with our team.

Benefits

AGV advantages for in-house logistics.

AGVs automatically bring required goods and raw materials to the right place at the right time. They take on physically demanding transportation tasks, and use comprehensive safety technology so they can share passageways with human operators and conventional industrial trucks. With camera-based 3D object detection, they integrate seamlessly into existing production environments.

The KMP 600-S diffDrive also can expand with 3D object detection for autonomous detection of obstacles from 50 mm to 2.1 m above the ground. At the same time, the KMP 600-S diffDrive is ideally equipped for the tough everyday environment of industrial production. Its IP 54 design always enables it to work reliably even under adverse conditions – including water spray and dust.

High safety standard

- Front and rear-mounted laser scanners

- 3D obstacle detection optionally available

- Four emergency stops

- Eight safety zones at both the front and rear of the vehicle

Extremely fast

- The AGV travels up to 2 meters per second

- Full speed in all directions of travel

- Integrated lifting device for lifting up to 60 mm in less than 3 seconds

IP54 protection rating

- Optimally equipped for the daily work of industrial production

- Protected against foreign matter such as (metal) dust

- Protected against water spray from any direction

Intelligent navigation

- Fleet manager software for the entire KUKA AGV portfolio

- Navigation via laser scanner and a map of the surroundings created in advance

- Identifies the fastest route – even in complex environments

Features

Durable multi-purpose performer with extensive accessories

Interfaces for any requirement

The KMP 600-S diffDrive can link a wide variety of workstations, thus providing precisely the load handling options the customer requires. For example, it acts as a top-load AGV (automated guided vehicle), as a carriage or by means of the integrated lifting device.

High positioning accuracy

Thanks to KUKA.NavigationSolution, KMP 600-S diffDrive can achieve a positioning accuracy of ±10 mm, without the assistance of orientation markings or reflectors. It can thus be used in many logistical production areas and impresses with its precise delivery of materials, automatic docking and autonomous operation.

Integrated lifting device

The lifting device is already integrated on the KMP 600-S diffDrive. This allows the AGV to lift pallets or cartons, for example, up to 60 millimeters – in less than three seconds.

Lithium ion battery

Each KMP 600-S diffDrive has an operating time of around eight hours and can be recharged in two hours. The AGV battery is characterised by its long service life.

Outstanding dynamic performance

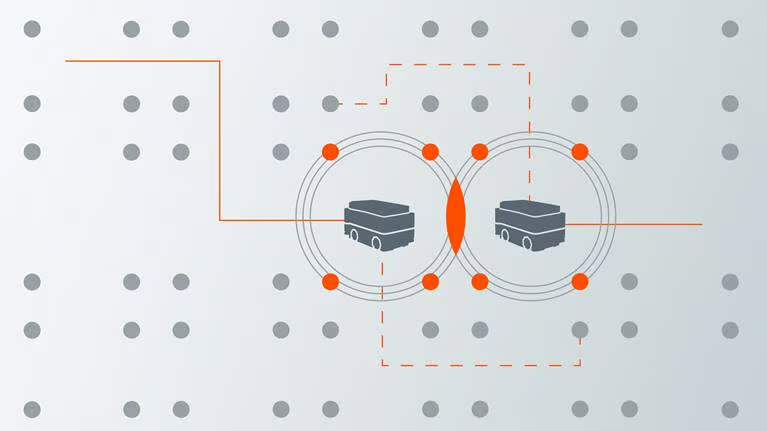

Eight safety zones

There are eight safety zones at both the front and rear of the KMP 600-S diffDrive that customers can customise to tailor them to the application situation. The protective field size is changed dynamically depending on the speed and direction of travel.

Purchase the KMP 600-S diffDrive now. Please speak with our team.

Software

KUKA.NavigationSolution:

The flexible solution for your automated guided vehicle systems (AGVS)

The KMP 600-S diffDrive comes with an ideal partner: KUKA.NavigationSolution. This software solution’s smart Simultaneous Localisation and Mapping (SLAM) algorithm maps the surroundings and takes over localisation in space (on the vehicle itself) as well as coordination of all the automated guided vehicles (on a central computer).

The fleet manager uses parameters such as distance and speed to determine the best route on the network of paths – avoiding all collisions. This software handles all mobility requirements.

Find out more about the KUKA.NavigationSolution. Please speak with our team.

For your specific requirements, talk to us.

To see how we can help with your systems or if you have any enquiry, please get in touch – we’ll be pleased to help. Send us an email at support@parmley-graham.co.uk or fill the form below.

Build innovative machines faster without costly prototyping with Efficient Motion Control.

With Effective Motion Control, machine builders can easily overcome major challenges and enable faster time-to-market, increased functionality, resolve complex system requirements, and demands for safety and sustainability.

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham is a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.