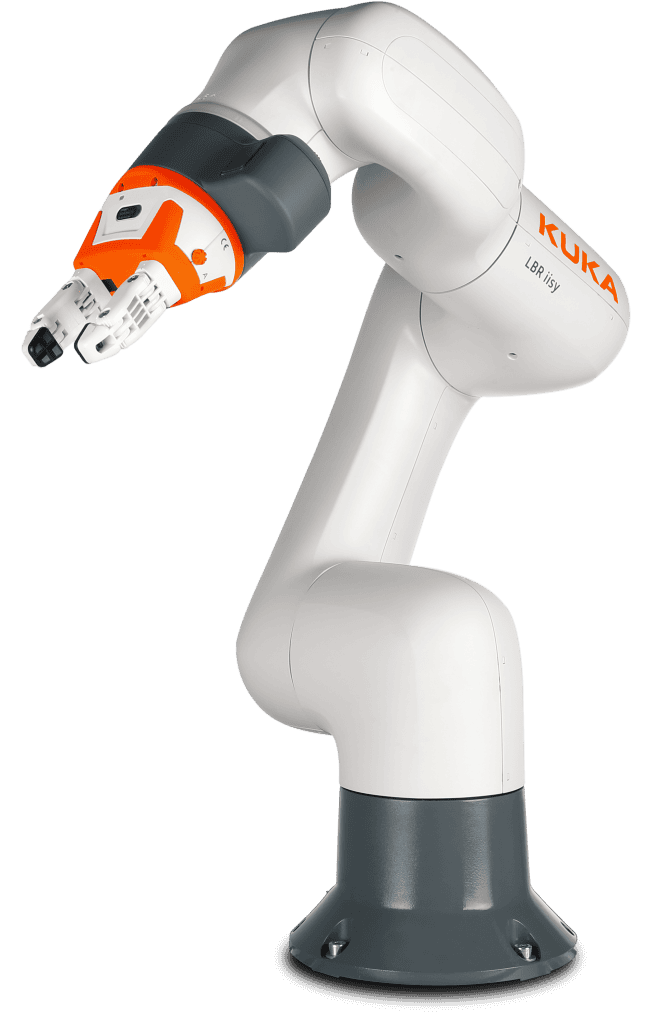

KUKA Robotics

Parmley Graham in partnership with KUKA Robotics offers a comprehensive suite of collaborative robotics solutions tailored to enhance productivity, efficiency and safety in industrial and manufacturing environments.

Browse our KUKA Robotics products below. For purchases and consultation, please speak to our team.

Dedicated Technical Support

Fast Delivery

Global Shipping

Certified Distributor

What is a Collaborative Robot (COBOT)?

By definition, a cobot is a collaborative or collaborating robot that works in close proximity to human employees. The alternative designations of corobots, collaborative robotics or cobotics are also used.

COBOT vs. Robot: How does it differ from a Industrial Robot?

Unlike traditional industrial robots, the collaborative robot may work with human workers in a shared workspace without a safety fence. Sensors ensure that the robot never injures its co-workers. Conventional industrial robots, on the other hand, require a physical safeguard for the safety of human workers, which prevents them from working together.

What can a collaborative robot do?

Watch the effective collaboration of cobots side-by-side with humans in both industry and medicine:

Human operators and machines work hand in hand in the assembly shop. Sensitive functions enable the joining of bevel gears and safe operation.

KUKA mobile cleanroom robot: Increased productivity for semiconductor manufacturing

Sensitive joining of bevel gears in human-robot-collaboration (HRC) Operation

What are the advantages of collaborative robots?

Collaborative industrial robots work safely and interactively. The robot systems can be moved easily from one station to another. They perform work steps that are laborious, monotonous or dangerous for humans, e.g. strenuous overhead tasks and meticulously detailed work. In this way, the machines optimize the processes and increase productivity for your production system by automating repetitive tasks. KUKA cobot systems at the plants of numerous users have already demonstrated that they can be put into operation very easily and that they pay for themselves quickly. Collaborative robots are also perfect for craftsmen and SMEs.

Flexibility & ease of use:

- Programming by Drag & Drop

- Manual guidance for easy robot motion

- Rapid startup in minutes

- Flexible conversion & programming for new work orders

- Easy reprogramming for frequent workpiece changes

Optimal cost-benefit ratio:

- Automated manufacturing is cost-effective even for small batches

- High technical availability ensures maximum utilization

- Low operating costs (TCO) over the service life

- Short delivery times

- Free delivery

How much does a collaborative robot cost?

Opting for and investing in automation is generally less expensive now than it was in the early days. The procurement costs usually pay for themselves after a short time due to the efficient application possibilities making the cobot a very cost effective option for the automation of your production. KUKA robot systems are characterised by low maintenance costs, and they run smoothly and can be checked regularly by experts.

Build innovative machines faster without costly prototyping with Efficient Motion Control.

With Effective Motion Control, machine builders can easily overcome major challenges and enable faster time-to-market, increased functionality, resolve complex system requirements, and demands for safety and sustainability.