Optimised Motion Series: low-cost with optimised performance

A package that makes moving and positioning easier than ever before while being significantly cheaper than conventional electrical solutions.

In the package: motor controller (drive system) with servolite technology including suitable cabling

Everything has a unique type code, making it easy to configure and order the right size and combination. This reduces the workload in your purchasing department and saves time, because the individual parts no longer have to be assembled.

Plus: quick parameterisation and commissioning thanks to web server/browser concept

Product in OMS at a glance

Electric cylinder EPCO

-

Making positioning easy and dynamic with the electric cylinder EPCO. It has a ball screw drive and non-rotating, plain-bearing piston, and always has a permanently mounted, perfectly tuned motor. The optional guide unit makes it even more powerful.

- Available in 3 sizes with strokes of up to 400 mm

- Optional guide unit with recirculating ball bearing guide with high load bearing capacity for absorbing lateral forces and protection against torsion at high torques

- Always with permanently fitted, optimally tuned motor and flexible, freely selectable 4 x 90 motor connection

- Cost-optimised controlled operation without encoder or controlled servo operation with encoder

- Optional proximity sensor for homing or position sensing

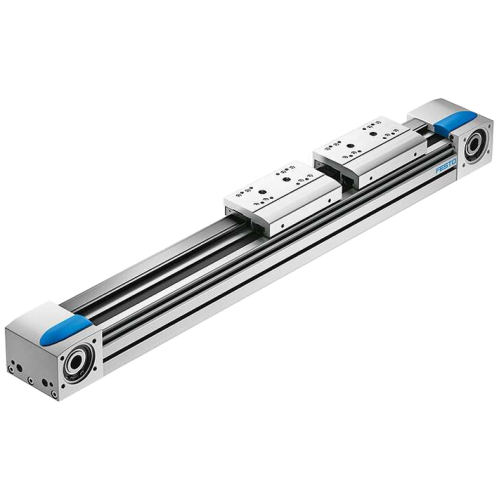

Toothed belt axis ELGR

The application-optimised toothed belt axis ELGR in cost-optimised design is ideal for applications with comparatively low requirements in terms of mechanical load, dynamic response and precision. The flexibility of the ELGR, as well as its diverse range of uses make it ideal for simple applications requiring cost-effective solutions.

- Available in 3 sizes for payloads of up to 6.8 kg

- Long service life at an operating performance of 5,000 km

- The motor position is freely selectable at both ends of the axis and can be retrofitted at any time

- Optional end-position sensing by inductive proximity sensors with a repetition accuracy of ±50 μm (radial)

Rotary drive ERMO

The application-optimised toothed belt axis ELGR in cost-optimised design is ideal for applications with comparatively low requirements in terms of mechanical load, dynamic response and precision. The flexibility of the ELGR, as well as its diverse range of uses make it ideal for simple applications requiring cost-effective solutions.

- Available in 3 sizes for payloads of up to 6.8 kg

- Long service life at an operating performance of 5,000 km

- The motor position is freely selectable at both ends of the axis and can be retrofitted at any time

- Optional end-position sensing by inductive proximity sensors with a repetition accuracy of ±50 μm (radial)

Configuration for OMS

Configuration with WebConfig

Quick and easy configuration and parameterisation: optimised commissioning with WebConfig. Quick and easy via the web server: download the parameter set from the parameter cloud and parameterise up to seven freely definable positions directly on the PC. The complete system is quickly and easily ready for operation.

Configuration with the Festo Configuration Tool FCT

Use the Festo Configuration Tool if you have special requirements for the Optimised Motion Series. With the software platform from Festo for electric drive solutions, you can configure up to 31 motion steps in the electric cylinder EPCO directly from the PC. You can enter acceleration values, speed, force or jerk limitation directly and use the advanced diagnostic functions. Flexible online or offline configuration and parameterisation without PLC.

Cost-effective multi-axis solutions with OMS

Multi-axis solutions in the Optimised Motion Series OMS system are easy to commission and operate – and can be mounted without the use of adapters. These attractively priced solutions for free motion in two dimensions are ideal for applications where small parts or workpieces need to be gripped, positioned, stacked, turned, assembled or packaged.

Create multi-axis solutions quickly and easily

Linear gantry for high dynamic response

- Combination of toothed belt axis ELGR and electric cylinder EPCO-KF as a dynamic two-axis handling system

- Toothed belt axis ELGR with strokes of up to 1.5 m and speeds of up to 1.1 m/s

- Electric cylinder EPCO-KF with external guide unit and maximum stroke of up to 400 mm

Compact pick & place solution

- Combination of two electric cylinders EPCO-KF

- External cylinder guide positioned vertically for a narrow installation profile

- Electric cylinder EPCO-KF with external guide unit and maximum stroke of up to 400 mm

Pick & place solution for precise positioning

- Combination of two electric cylinders EPCO-KF

- Electric cylinder with recirculating ball bearing guide for high repetition accuracy in motion and positioning

- Electric cylinder EPCO-KF with external guide unit and maximum stroke of up to 400 mm

Low-cost, mixed-technology pick & place

- Combination of electric cylinder EPCO-KF and pneumatic slide DGSL

- Electric cylinder with recirculating ball bearing guide for free positioning and motion

- Low-cost pneumatic slide DGSL for maximum accuracy and guide precision

Precise and resilient rotary lifting solution

- Combination of electric cylinder EPCO-KF and electric rotary drive ERMO

- Electric cylinder with recirculating ball bearing guide for flexible linear positioning

- Electric rotary drive with sturdy, backlash-free bearing for absorbing high forces and torques

Build innovative machines faster without costly prototyping with Efficient Motion Control.

With Effective Motion Control, machine builders can easily overcome major challenges and enable faster time-to-market, increased functionality, resolve complex system requirements, and demands for safety and sustainability.

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham is a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.