Chemical Manufacturing

New solutions for greater efficiency, greater sustainability, and a greater future.

Overview

Process optimisation in the chemical industry: Making the most of your changing options.

Chemistry is life, and life is becoming increasingly digital. Transforming the industry into Chemical Industry 4.0 is a challenge. And a tremendous opportunity. The amount of data in the Industrial Internet of Things (IIoT) allows us to use limited resources more efficiently than ever and to proactively optimise plant operation. To enable you to harness the potential of digitalisation in the chemical industry, we provide solutions with a clear perspective, so that you can be certain that your plants and your business continue operating, including in the world of tomorrow, thanks to digitalisation expertise and a lively partnership, proven technology for chemical production, and sustainable solutions that can be seamlessly integrated – real, digital, everywhere.

Solution

Chemical Industry 4.0 provides new solutions for greater efficiency, greater sustainability, and a greater future.

Digital Twin - driver of the digital revolution

In the Digital Twin, performance data acquired in the physical world enables a continuous and open optimisation cycle for the product and production. The comprehensive digital twin integrates all the necessary components, which in turn allows it to simulate and optimise all processes digitally along the entire line – for quickly adapting production or for predictive maintenance.

Digital Worker – empowered to perform

Global demand for electric vehicles is growing. However, customers still demand conventional drivetrains and increasingly more custom design options. To meet these challenges, digital twins can help to improve efficiency and flexibility.

Integrated maintenance – solve problems before they occur

Creating autonomous vehicles demands agile, model-based development with integrated data flows and a heavy reliance on software-based simulation capabilities. Siemens PLM Software offers a full set of autonomous vehicle solutions for all key technical domains – from chip design to full vehicle validation.

Integrated engineering and operation – a data view of everything

Working in an integrated fashion means that data is entered only once, that different applications communicate with one another, and that the data collected is fully exploited, for greater efficiency and safety, and for more flexibility. The goal is a convergence of the real and digital worlds, the optimisation of processes in the chemical industry, and the seamless integration of the entire value chain, from design to implementation.

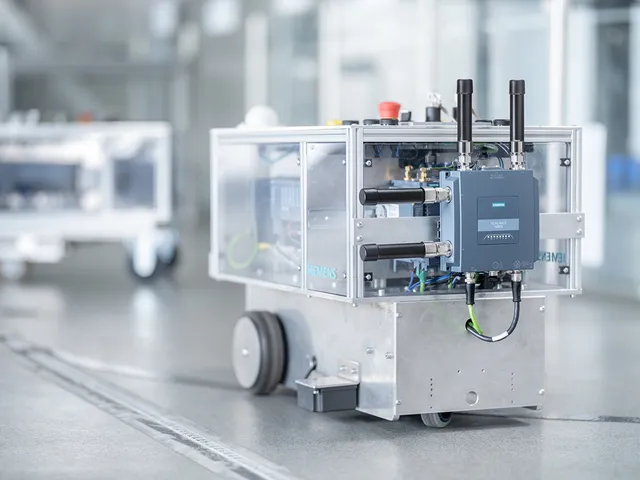

Logistics – digitalise the supply chain

Process optimisation in the chemical industry starts with the supply chain and logistics. For example, it’s important to ensure a reliable supply of raw materials throughout the entire manufacturing process. Digitalisation offers new opportunities for connectivity, data exchange, and interoperability among partners. We want to work with you to develop new, digital solutions that drive your plant operation forward.

For your specific requirements, talk to us.

To see how we can help with your systems or if you have any enquiry, please get in touch – we’ll be pleased to help. Send us an email at support@parmley-graham.co.uk or fill the form below.

Key advantages

Taking advantage of opportunities for process optimisation in the chemical industry

Digitalisation provides the chemical industry with innovative ways to approach process optimisation and modularisation, engineering and plant operation, and product development and maintenance that are integrated throughout the entire plant lifecycle.

Maintain plants proactively

Intelligent digital technologies and the continuous analysis of operational data minimise costly downtimes while at the same time enabling more effective and targeted maintenance. Digitalised plants are more stable in operation, extending the service life of components enabling digitalisation make the chemical industry safer.

Respond flexibly to market requirements

Through innovative networking of in-house and external data, you can predict demand, improve processes, and optimise plants throughout their entire lifecycle. Digitalisation enables the production of smaller and smaller batches in order to meet very specific requirements – making the chemical industry more flexible.

Think ahead and optimise processes

With digital transformation driving automation and modular production, processes can be pre-conceptualised in a digital twin and optimised in near real-time. Digitalisation of workflows, 3D virtualisations of products or of the entire factory, or upstream and downstream processes like logistics makes the chemical industry smarter.

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham is a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.