Siemens Process Controlling and Protection

Siemens devices for process protection form a reliable early warning system. Their robust construction means they are insensitive to dust, dirt, deposits and humidity. Our non-contacting acoustic sensors measure inaudible high-frequency noise emissions, while our non-contacting speed sensors record changes in drive and speed in your piston, turning and conveyor systems.

Intelligent process protection

Process protection devices act as early warning systems to avoid costly process interruptions and breakdowns of equipment. Noncontacting motion sensors detect changes in motion and speed of conveying, reciprocating and rotating machinery.

Non-invasive acoustic sensors detect inaudible, high frequency acoustic emissions generated by friction and impact, caused by materials in motion. They can detect conditions of flow/no flow or high/low flow, to warn of blockages, product absence or equipment failure. They are located outside of the process, accurately detecting conditions without wear on the sensor.

Motion sensors can warn in case of equipment malfunction and shut down machinery in case of a slowdown or failure. They are rugged and perform even in harsh industrial conditions. Most of the MFA 4p motion sensing probes, as well as the SITRANS WM100, can be mounted up to 100 mm (4 inch) from the ferrous target, reducing the chance of damage to the probe and the equipment. The probes are not affected by moisture or dust build-up.

Early detection protects your process.

In order to avoid costly process interruptions and system downtimes, process control devices serve as early warning systems. They detect flow problems, blockages, screening disturbances, speed changes and filter cracks. Due to their robust construction, these devices are insensitive to dust, dirt, deposits and moisture.

Intelligent process monitoring

Process monitoring is a prerequisite for safe, high-availability processes. Siemens offers the necessary equipment for highly reliable process control. Process monitoring enables early recognition of flow problems, blockages, screen and filter faults, or cavitation in pumps. This avoids unplanned, costly process interruptions and plant downtimes.

Acoustic Sensors

Pump monitoring and material flow monitoring

With SITRANS DA acoustic sensors for pump monitoring, even the smallest leakages on delivery valves of oscillating positive displacement pumps (e.g. piston pumps) can be detected by measuring cavitation. SITRANS AS100 is an acoustic sensor used for solids flow detection. The AS100 can be connected to a SITRANS CU02, which processes signals from the sensor, providing relay and analog outputs for connection into a process, or it can be connected directly to a PLC analog input.

Motion Sensors

All of the MFA 4p motion sensing probes can be mounted up to 100 mm (4”) from the ferrous target, reducing the chance of damage to the probe and the equipment. The probes are not affected by moisture or dust build-up

Process Controllers

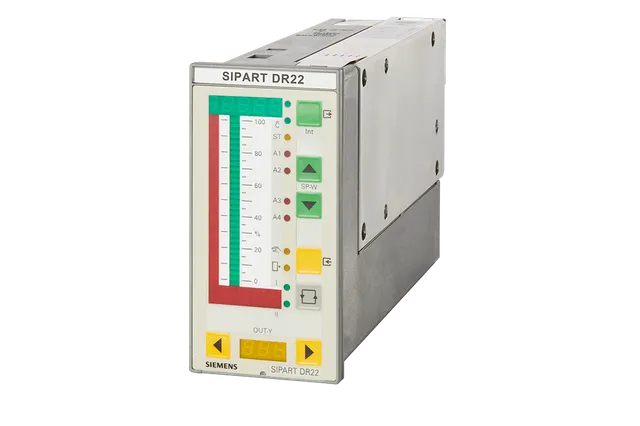

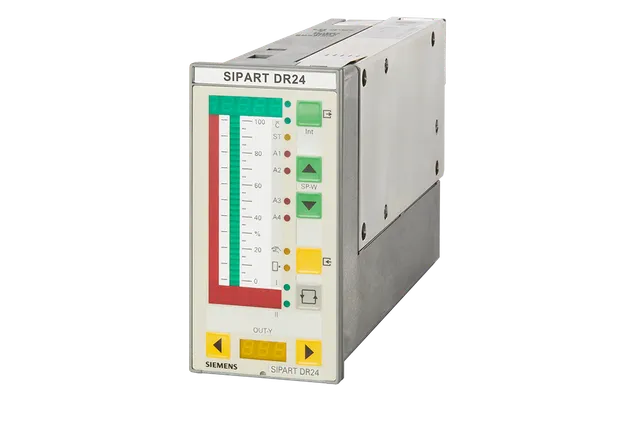

SIPART DR Process Controllers

A suitable controller is available for every area of application – from fixed setpoint control all the way to complex control tasks.

The SIPART DR controllers are characterised by high reliability in addition to simple operation. Functional extensions can be realised quickly and easily with plug-in option modules.

Compact controllers are ready-to-use control devices for many applications which can do more than just control thanks to comprehensive functions. Despite all this flexibility, they also impress with their simple handling.

Process Recorders

Display recorders of the SIREC D series are used for continuous monitoring of process variables in plant maintenance and process optimization or in troubleshooting.

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham is a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.

Build innovative machines faster without costly prototyping with Efficient Motion Control.

With Effective Motion Control, machine builders can easily overcome major challenges and enable faster time-to-market, increased functionality, resolve complex system requirements, and demands for safety and sustainability.