Robotics Industrial Automation

Unlocking the full potential of robotics and automation - driving sustainable growth and competitiveness in industries.

The slowly declining cost of robotics over the years led to physical robotics technology becoming more accessible to many businesses. However, the complexity of systems design, programming and integration amongst other problems remain a challenge to many developers.

With automation being the norm in todays’ industrial landscape, it is a huge advantage for any business to implement the right systems and applications.

Discover our solutions and various area of focus within industrial automation and Industry 4.0 below. For your specific enquiries, please speak with our team.

Get 30%+ discount and dedicated support from Parmley Graham

Automation Starter Bundles

Don’t miss it. | Find out more

Understanding and addressing various implementation challenges within industrial robotics and automation.

The industry’s quest to develop automated systems to handle industrial processes and machineries is fast progressing. Despite the significant advancement and availability of robotics and industrial automation technologies, industry system developers still face relevant issues that seriously affect their development speed, quality of output and project cost.

In order to successfully substitute manual labour with machines and robots for improved efficiency, speed, quality, performance and safety in their production, it is important that these challenges are addressed when developing sustainable solutions.

These challenges are the following;

The upfront investment in robotics technology, including hardware, software, and training, can be substantial.

Integration with existing systems and ensuring that new robotic systems can seamlessly integrate with current machinery can be complex and costly.

The complex process of designing and programming robots to handle specific tasks requires advanced expertise and can be time-consuming.

Robotic systems require regular maintenance, and any downtime can be costly and disruptive to production.

As robots become more connected, they are increasingly vulnerable to cyberattacks, necessitating robust security measures.

Developing and deploying robotic systems must consider ethical implications and comply with regulatory standards, which can vary by region.

The production and disposal of robotic systems can have significant environmental impacts, requiring sustainable practices and materials.

Scaling robotic systems to different sizes of operations or adapting them to varied tasks can be challenging.

Achieving consistent reliability and precision in robot performance, especially in complex or variable environments, remains a significant challenge.

The need for an integrated solution that addresses all these issues!

Addressing the challenges is crucial to the success of robotics industrial automation systems, that’s why at Parmley Graham, we developed a range of solutions that will cater to your individual needs.

- Our range of robotics units and solution provided by world’s top manufacturers offers a great-value investment that can accelerate delivery of your return on investments (ROI).

- Siemens’ technology enables simple and easy robot integration solution enabling seamless integration with existing systems, minimising disruption and accelerating time-to-market

- Being a market leader in industrial automation supply, we leverage our expertise and industry know-how to curate and develop advanced solutions that covers different aspects such as cyber security, regulatory and ethical compliance, training – whilst providing cutting-edge products and technology in the fields of automation, process and motion control, and many other applications for the industrial and manufacturing sector.

Robot Integrator

Simplifying the complex process of robotics system integration

Robot integration made easy - ensuring compatibility, interoperability and fast deployment.

- Use robots from different vendors

- Reduce complexity of introducing robots

- Reduce project and manufacturing costs

- Achieve data transparency

- Implement and deploy easily

Speak with our experts to discuss your requirements or find out more about our solutions below.

Siemens Robot Integrator

Integrated solution for robots from different manufacturers with one application.

Achieve more while reducing the amount of engineering and operational complexity with Siemens’ SIMATIC Robot Integrator which makes the benefits of robotics readily available to all users. The SIMATIC Robot Integrator is a ready-to-use solution that enables the integration of robots from a wide range of manufacturers without external assistance.

Integrating robots has never been easier and faster with Siemens’ TIA Portal which now has the capability of speaking robotic language through the SIMATIC Robot Library – this enable machine builders and end-users new opportunities for greater flexibility and efficiency while helping save on engineering costs and users benefit from a single engineering environment for machines and robots.

Robotics

High performance, safe and efficient robots for different applications.

Easy to program and easy to operate.

Investing in industrial robots deliver substantial value with significant return on investment through;

- Increased productivity

- Reduced labour costs

- Enhanced precision

- Improved operational efficiency

- Excellent for highly-repetitive tasks

Talk to us about your requirements, or find out more details below.

Industrial, collaborative, mobile platforms and mobile robots

A range of industrial and collaborative robots to suit any process requirement.

Parmley Graham launched its robotics portfolio earlier in 2024, showcasing KUKA’s collaborative robots and Stäubli’s industrial robots range. This means, these sought-after and cutting-edge robotics technology will be available through Parmley Graham’s distribution channels which was aimed to further elevate the landscape of industrial automation across the UK.

By capitalising on the strengths of both companies, KUKA and Stäubli who are renowned experts in robotics and automation – Parmley Graham’s deep understanding of the UK market and its unique requirements can now offer customers a comprehensive suite of industrial and collaborative robotic solutions tailored to enhance productivity, efficiency, safety and business value in the UK manufacturing industry.

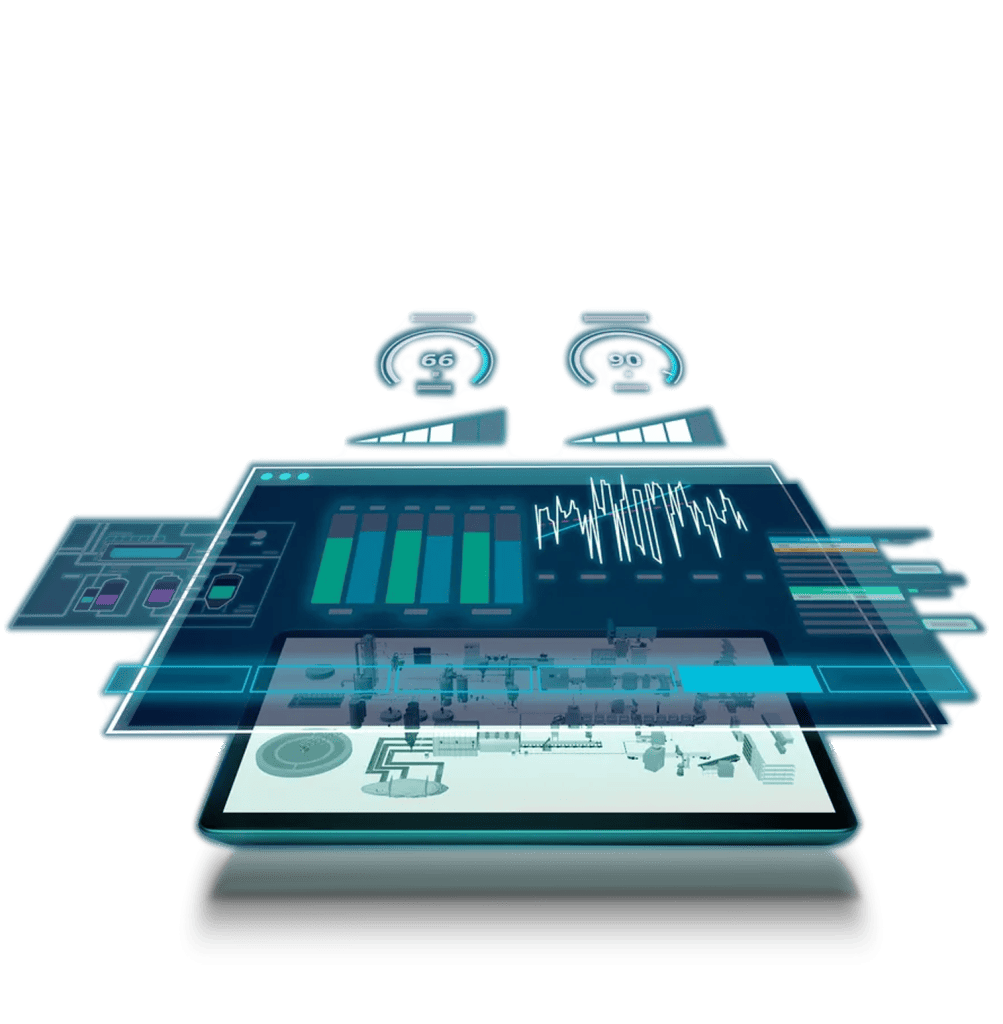

Industrial Automation

Hardware and software integration for systems efficiency and reliability.

Discover our Automation Solution.

Speak with our experts to discuss your requirements.

Get 30%+ discount on Automation Starter Bundles.

Our industrial automation technology supplies encompass advanced technologies such as controllers, sensors, drives and other elements - essential for optimising manufacturing process, enhancing efficiency and ensuring seamless integration across diverse industrial applications.

Controllers

Drives

Our selection of drives with integrated safety can be centrally installed in control cabinets, mounted on walls or decentrally. They operate with energy-saving performance, for every function whether for pumping, ventilating, moving, positioning, processing or machining.

HMIs

Software

Ensuring a high level of functionality and efficiency in all phases of a plant’s or machine’s life cycle, from the field to the corporate management level. The SIMATIC software range from Siemens helps you to shorten your time-to-market through simplified engineering and simulation tools, as well as to increase performance via diagnostics and energy management.

Visit our Industry 4.0 Centre and see our robotics and automation setup in action.

The Parmley Graham Industry 4.0 Centre is a mirror of the Siemens Digital Experience Centre based in Manchester and is filled with technology from micro automation, servo drives, redundant PLC’s, automation safety solutions and networks.

With the addition of robotics into our automation range, you will also be able to see KUKA’s LBR iisy collaborative robot in action as part of our demonstration. Experience the wonder of robotics and automation integrated using Siemens Robot Integrator.

Book a tour to our Industry 4.0 Centre

Find out more about our Industry 4.0 Centre

Cybersecurity

Optimise the benefits of industrial automation without the risks of cyber attacks.

Overcome the industries' greatest challenges on digitalisation through optimally and securely handling data at all times.

IEC 62443 and NIS2 Regulation Compliance

The solution to protect automation systems and OT against cyber threats

Defence-in-Depth is a multi layered cybersecurity concept which provides an effective protection to automation plants to enable operators, integrators and component manufacturers to cover all security-related aspects of an industrial entity – based on the IEC 62443 requirements.

At the same time, the EU cybersecurity legislation called the Network and Information Security 2 (NIS2) requires a mandatory implementation of measures which the Defence-in-Depth is specifically designed and developed for, to combat cyber crimes and improve the security management for European and national companies.

Understand the importance of addressing the issues of cybersecurity and how we can help you accelerate your compliance with the legal requirements.

Motion Control

Precision and reliability for automation and robotics systems.

Enabling accuracy and reliability of kinematic components of automation systems for enhanced level of precision, productivity and safety in operations.

Simplify your application. Siemens' integrated motion control system solution with one easy and intuitive engineering tool accelerates development time.

We help you efficiently configure and program complex motion control applications with system-integrated editors for configuring individual dependencies between coordinated axes. All this can be done in a single familiar programming environment.

Implement and operate easy and fast robots and custom kinematics for repetitive handling tasks in a production machine or line. Control and use robots, machine automation and safety solutions that monitor kinematic movements in the 3D Cartesian space in one controller.

Using a standardised engineering language for your robot application to simplify and standardise robot engineering and operation, our solutions provide a unified interface between robots from any vendor and the machine PLC, handling robots and automation in a single engineering framework.

Efficient Motion Control

Simplifying the complex engineering of motion and kinematics within industrial applications.

Developing single and coordinated axes is complex. Multiple different motion control system components and solutions make optimisation challenging, and implementing these solutions can be risky and costly. As a result, building and automating a production line efficiently where different systems work together can be extremely difficult.

Machine builders are commonly faced with a challenge to modernise machine concepts and realise new production approaches to meet the demand of industry, with batch sizes of one and consumer demand for individualisation and a faster delivery time.

The difficulty to program complex movement, and the need for specialist technology and specialist knowledge to develop sophisticated motion can be addressed through a seamless integrated motion control solution that can simplify build, engineering, and execution – together with our partners, we made this easy for you by providing a solution that will exactly let you do that.

Explore our Efficient Motion Control solution and understand how automation can deliver your business advantage to a new height.

For your specific requirements, talk to us.

To see how we can help with your systems or if you have any enquiry, please get in touch – we’ll be pleased to help. Send us an email at support@parmley-graham.co.uk or fill the form below.

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham is a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.