Simulation

Simulation and Digital Twin - Integrate real-world objects into the digital world.

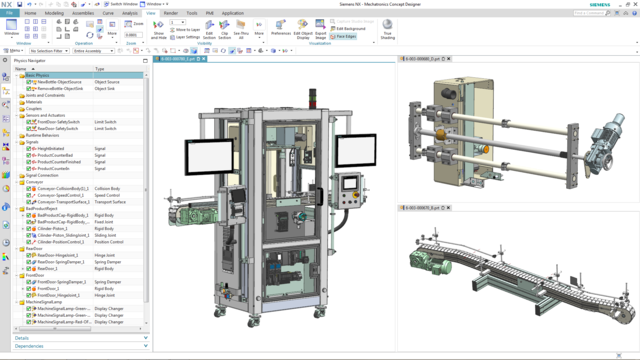

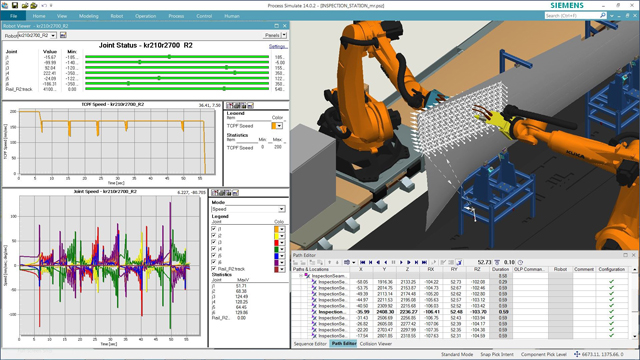

Virtual commissioning enables you to optimally prepare your system operators for the start of production, even before actual commissioning begins. The result? Fast, high-quality and safe commissioning.

Dedicated Technical Support

Fast Delivery

Global Shipping

Certified Distributor

Overview

Inside a Digital Twin

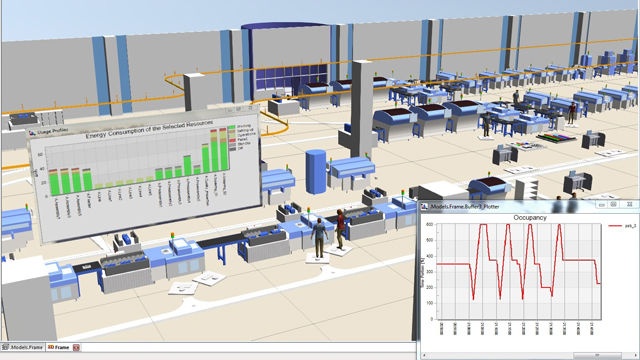

A Digital Twin integrates all data, simulation models, and other information from a physical object generated during engineering, commissioning, operation, and service and are provided to designers, engineers, operators, and service technicians across vertical domains.

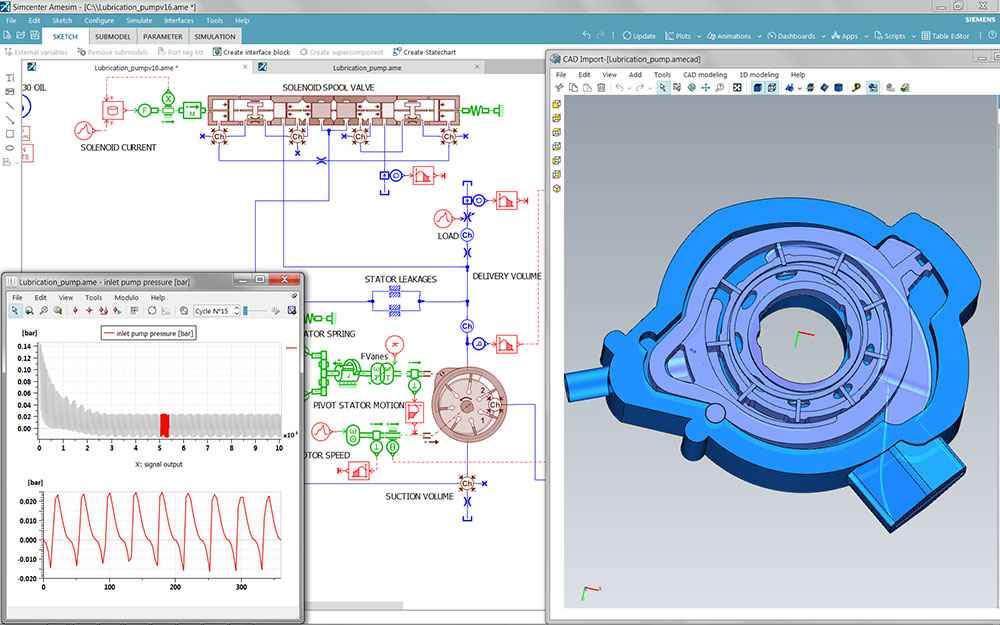

The core component of many Digital Twins is a simulation model that implements the behaviour of the simulated object. While simulation technology and mathematical modelling has been used for several decades, the options for creating digital twins have improved significantly in recent years due to breakthroughs in solver technology and semantic methods and the vast availability of fast computing hardware and virtual reality technology.

Siemens Core Technologies

As a Siemens Approved Partner, we have access to complex technological products. This means we can fully enable digital twins solutions, help our customers design them faster, make them more powerful, and enable to operate them more effectively.

The Siemens software solutions also provide our customers with tools to create and use digital twins for their own products.

While those products and solutions cover a broad range of applications, there are significant universal challenges across the domains that we address in the CCT Simulation and Digital Twin. These include the following;

- Simulation of complex multi-physical and multidisciplinary systems

- Semantics and knowledge graph technologies to create a digital twin fabric

- Combining machine learning and simulation; our executable digital twin that can be leveraged in real time during the operation of an actual asset

- Generative engineering methods for automated support of design engineers; and virtual and augmented reality technologies.

Virtual commissioning and operator training with SIMIT

SIMIT: Enabling increased lifecycle efficiency by simulating reality

Direct integration of engineering data

Increased quality

Faster time to market

High plant availability

Increased operator know-how

Reduced costly production or plant downtimes

Real-time simulation for more safety and reliability

With SIMIT, you can comprehensively test automation projects and commission systems, machines, and processes on a platform at a virtual level. The simulation platform can also be used to create realistic training environments for operating personnel.

Real-time simulation

A foundation for your digitalisation strategy

With SIMIT, you can perform simulations on a single platform that enable both comprehensive tests of automation projects and the virtual commissioning of systems, machines, and processes. Simulation means more efficiency throughout all stages in the lifecycle of manufacturing and process plants. At the same time, simulation opens up an easy opportunity for process optimisation and know-how retention.

Unlike the real world, real-time simulation provides you with a protected space for new test scenarios that can be reset or saved whenever or as often as you want. SIMIT impresses with its flexible and scalable simulation structure and an intuitive user interface. A wide range of communication opportunities between SIMIT and external simulators lets you use existing knowledge for even more realistic simulations.

Virtual commissioning

Commissioning made faster

Operator training

Reduce risk with operator training

More efficiency throughout the system lifecycle

From development of a new product to optimisation of the system during live operation: Simulation with SIMIT lets you test and optimise in a virtual environment with no risk before you implement everything for real – and it will all work right away.

To find out more about Siemens SIMIT, please speak with our experts.

For your specific requirements, talk to us.

To see how we can help with your systems or if you have any enquiry, please get in touch – we’ll be pleased to help. Send us an email at support@parmley-graham.co.uk or fill the form below.

The SINAMICS DriveSim Family

The ultimate solution for designing, commissioning and optimising your drive train system – with two powerful options available: the Basic and Advanced.

Thanks to its intuitive interface, you can quickly set up and configure your digital twin and start simulating different operating conditions and scenarios. By adding the digital twin to your machine simulation, you can speed up your design and engineering phase while improving machine quality and robustness.

Don’t miss out on this incredible opportunity to take your drive train system to the next level with SINAMICS DriveSim Family.

Key advantages of SINAMICS DriveSim Family

Compatible with many simulation programs

As a standardised FMU model, the virtual drive of DriveSim Designer is compatible with many market-standard simulation programs such as: SIMIT, Simcenter Amesim, NX Motion, Matlab Simulink, Ansys TwinBuilder, ISG Virtuos.

SINAMICS DriveSim Advanced on the other hand is directly integrated in TIA Portal, so you do not need different software tools to use it.

Verified and validated in the test lab

Easy to apply and operate

Time-saving, fast simulation

To find out more about Siemens SINAMICS, please speak with our experts.

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham is a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.