Intralogistics

Intelligent intralogistics –experience the flow!

Challenges

Overcoming your challenges.

Realise sustainable warehouses and material handling equipment

- The Digital Twin approach, based on improved collective intelligence, looks at the entire product lifecycle and helps to manage carbon footprint across the supply chain.

- The digital twin delivers data, insights, and next best actions to optimise the energy efficiency of material handling equipment or whole warehouse operations

Utilise digitalisation to gain a competitive advantage

- By utilising the digital twin of material handling equipment you can boost productivity in machine and workplace design through collaborative multi-domain engineering processes.

- The digital twin enables optimisation in the virtual world before the findings are implemented in the real world, enabling a new world of intralogistics possibilities.

Secure warehouses from the threat of cyberattacks

- With “defense in depth”, Siemens provides a multilayer security concept that gives warehouses both all-round and in-depth protection as recommended by the international standard IEC 62443.

- The approach covers all levels simultaneously – from the operational to the field level and from access control to copy protection – to comprehensively protect warehouses against internal and external cyberattacks

Realise safe working environments in warehouses

- With Safety Integrated, we’re providing an intelligent answer to the steadily increasing requirements for functional safety in machines and plants.

- With significantly reduced engineering effort, our concept ensures safe, reliable, and economical operation and thus greater availability and system consistency by integrating safety technology into standard automation.

Realise a digital distribution center and warehouse

- We are offering end-to-end solutions to benefit from transparency across all core elements of a digital infrastructure – industrial communication and network, 5G technology, industrial identification and location via power supplies.

- A powerful digital infrastructure ensures secure collection, transmission and storage of all relevant data and information from which real added value can be generated to make distribution and warehouses smarter, more flexible and more profitable.

Solution

Digitalisation for intralogistics – your key competitive edge.

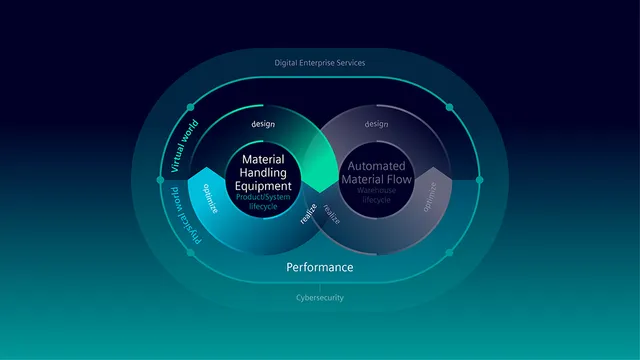

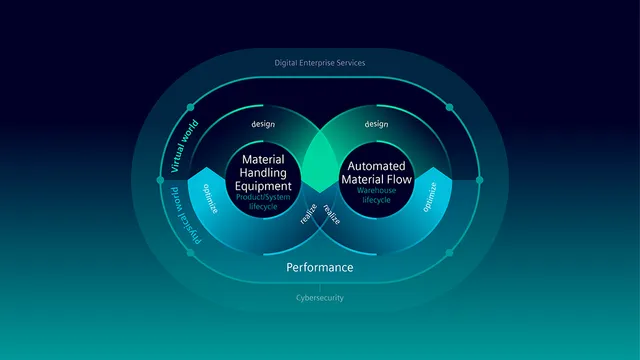

We help machine manufacturers and end customers to access the advantages of digitalisation with our consistent end-to-end portfolio for all key warehouse technologies. Equipping autonomous guided vehicles, conveyors and automated storage systems with seamlessly integrated automation and drive systems is just one part of our offering. The digital twin enables optimisation in the virtual world before the findings are implemented in the real world, enabling a new world of intralogistics possibilities.

The digital twin of material handling equipment: Product and system lifecycle

- Digital twin of mechanical and electrical equipment

- Simulation of material transport systems automation

- Automatic generation of PLC codes, i. e. virtual commissioning

This enables significant time savings and quality improvements in the PLM process.

The digital twin of automated material flow: Warehouse lifecycle

- Machine status in distributed systems Power consumption Maintenance information

- Analysis of operating conditions as a trend analysis

- Comparison of real and planned operating conditions to close the feedback loop with the planning phase

To achieve further optimisation, systems must be made transparent and data analysed in distributed, heterogeneous environments. This involves not just obtaining and analysing data but also linking the data analysis with equipment- and application-specific knowledge. Insights Hub, the cloud-based open IoT operating system from Siemens, provides all options for these operations.

For your specific requirements, talk to us.

To see how we can help with your systems or if you have any enquiry, please get in touch – we’ll be pleased to help. Send us an email at support@parmley-graham.co.uk or fill the form below.

Benefits

Optimise opportunities from infinite data

Seize the benefits of becoming a Digital Enterprise with Siemens Xcelerator.

By transforming into a true Digital Enterprise, warehouse operators can collect, understand and use the infinite amount of data created in the Industrial Internet of Things (IIoT). The result: A continuous loop of optimisation in near real-time, maximum transparency, and reduced resource consumption to make industry more sustainable. With Siemens Xcelerator – the easy, flexible, and open digital business platform – we help our customers to accelerate their digital transformation to become a Digital Enterprise.

Benefits for Material Handling Equipment Manufacturers

- Shorten time-to-market by applying digitalisation from concept to innovation

- Improve efficiency of application development by combining digital twin solutions with comprehensive domain expertise

- Enable new roles and business models with digitalisation

- Maximise productivity and availability

- Minimise systems’ expenditure of time and resources through digital twins

Benefits for Warehouse Operators

- Test the idea in a virtual world and to optimise the outcomes together with associated costs

- Improve the performance of systems’ processes using operating data and the digital twin

- Realise business development with minimum of risks

- Save time and money through complete control of the material handling systems with the digital twin

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham is a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.