Automotive Manufacturing

Embracing digitalisation and state-of-the-art hardware to survive the present and win the future.

The dynamic development in the automotive industry is continuously increasing and confronts companies with new challenges. Worldwide demand for electric cars is on the rise, while the driving public – also those of us unwilling to make the move away from conventional drive systems – dreams of ever more individually designed cars.

To stay relevant in this fast-changing market, manufacturers can streamline all aspects of product design, development, and manufacturing through state-of-the-art manufacturing hardware and software that can intelligently turn production lines into autonomous, self-organising operational environments.

Overview

Bringing the future into the factory with efficient production, intelligent automation, and virtual manufacturing development

The automotive industry is reshaping faster than ever before. Technology advancements are redefining transportation from traditional mechanics to complex sustainable, entertaining, and connected mobility enabled by electronics and software. Automotive manufacturers are under intense pressure to innovate and bring electric vehicles and autonomous features to market faster, increasing production complexity and forcing them to shorten timelines. With Siemens as our partner, we provide smart manufacturing solutions that can enable you can modernise manufacturing lines faster, make better decisions based on real-time insight, use virtual commissioning to launch successfully, and ensure the on-time production of innovative, high quality, and compliant products.

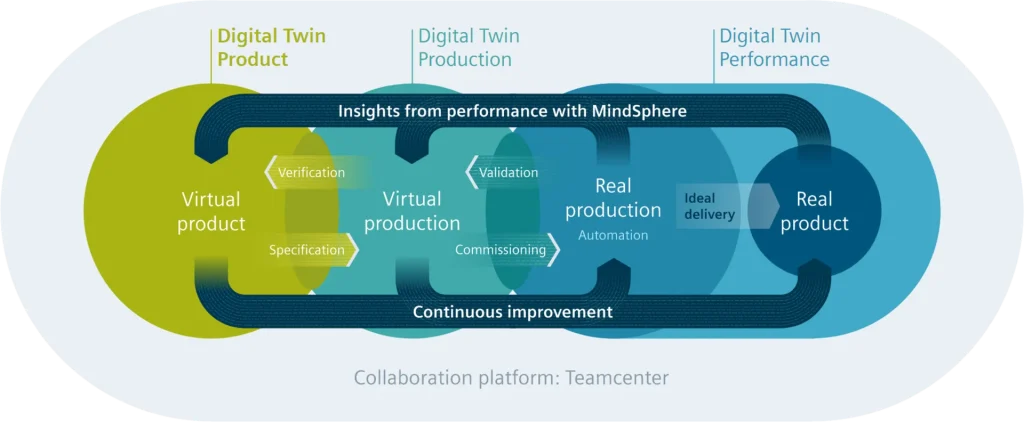

Digital Twin

The digital twin in the automotive industry is the precise virtual model of a vehicle or a production plant. It displays their development throughout the entire lifecycle and allows operators to predict behaviour, optimising performance, and implement insights from previous design and production experiences. Our comprehensive concept of the digital twin consists of three forms: the digital twin of the product, the digital twin of production, and the digital twin of the performance of both product and production. Thanks to our comprehensive domain expertise and optimised tools, Siemens is the only company that offers this holistic approach.

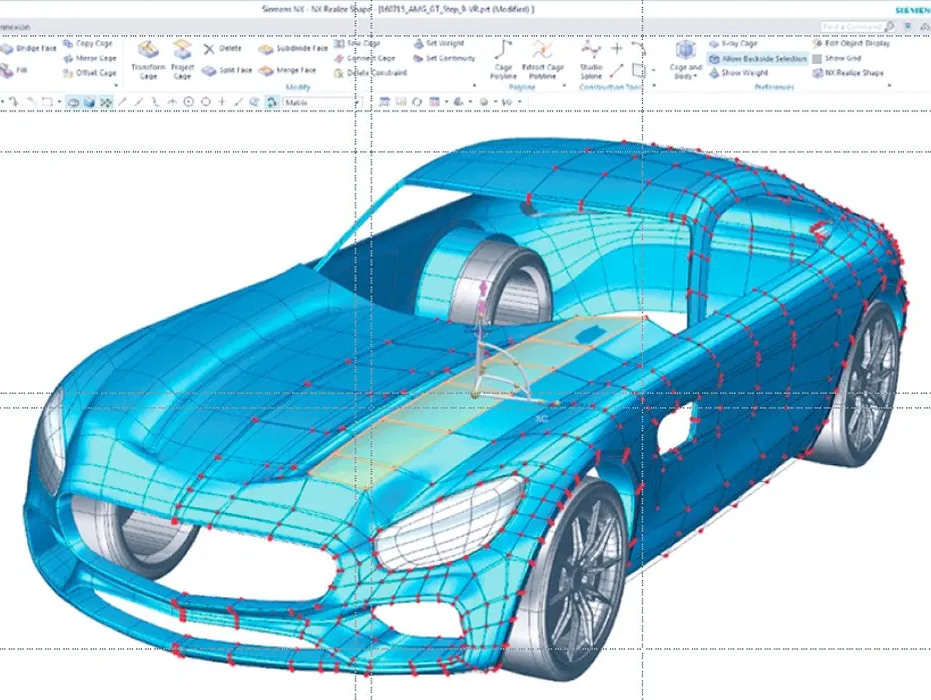

The digital twin of the product

The digital twin of the product enables realistic simulations to optimise the car before it’s being built.

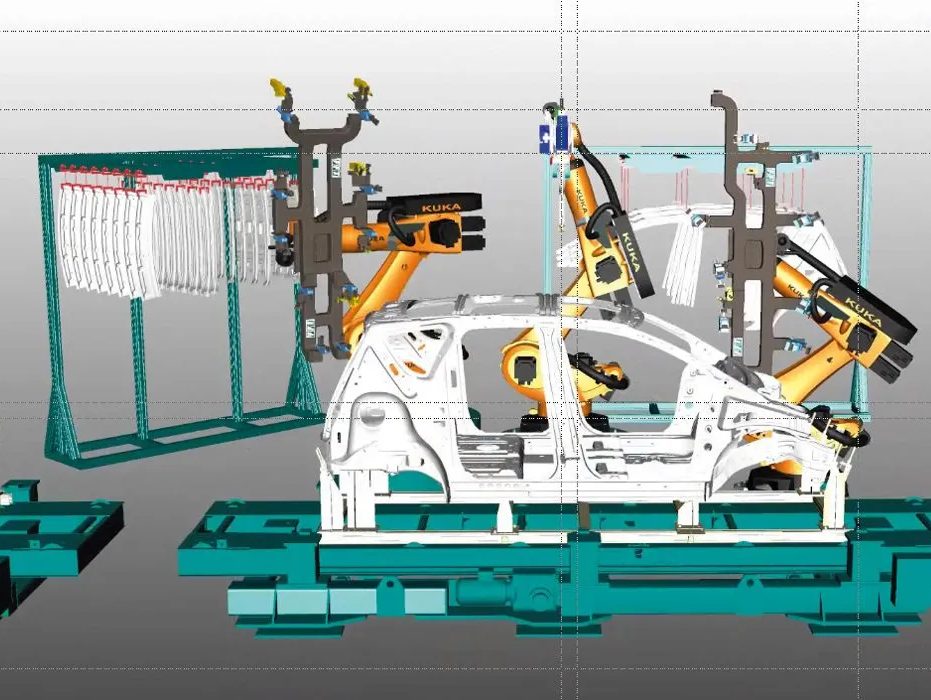

The digital twin production

The digital twin production enables to optimise production before it begins by virtually commissioning the new production cell or line.

The digital twin of performance

Taking quality management and data analytics to new levels enabling efficient, smooth and secure production.

Find out more about the Digital Twin solutions.

Application Examples

Artificial Intelligence (AI)

By interlinking production with artificial intelligence (AI) technologies – even during production, it is now possible to automate processes that were previously difficult or impossible to automate. Thanks to an innovative combination of digital methods and intelligent applications. With the help of artificial intelligence, robots are learning to recognise damage to car bodies – and thus to produce even better in the future.

eCar Production

Global demand for electric vehicles is growing. However, customers still demand conventional drivetrains and increasingly more custom design options. To meet these challenges, digital twins can help to improve efficiency and flexibility.

Autonomous Driving

Creating autonomous vehicles demands agile, model-based development with integrated data flows and a heavy reliance on software-based simulation capabilities. Siemens PLM Software offers a full set of autonomous vehicle solutions for all key technical domains – from chip design to full vehicle validation.

Industrial Identification

What? Where? When? End-to-end transparency of status, location, and time of objects is the basis for digital production and intralogistics. Identify and locate along the automotive production chain from the body shop to the battery pack production with more integrated and scalable systems.

Talk to us about your requirements and speak with one our experts.

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham is a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.