Visualisation

A complete system of hardware and software that offers a consistent range of functions– for a wide range of applications in every industry.

Implement consistent, end-to-end industrial visualisation solutions that place the highest demands on industrial control and monitoring. Benefit from maximum efficiency in engineering and implement innovative control with a brilliant display – directly at the machine and for monitoring lines and complex plants.

Find out more about our solutions or browse our Visualisation products.

Overview

Seamlessly integrated hardware and software for every visualisation task.

A complete system of hardware and software that offers a consistent range of functions– for a wide range of applications in every industry.

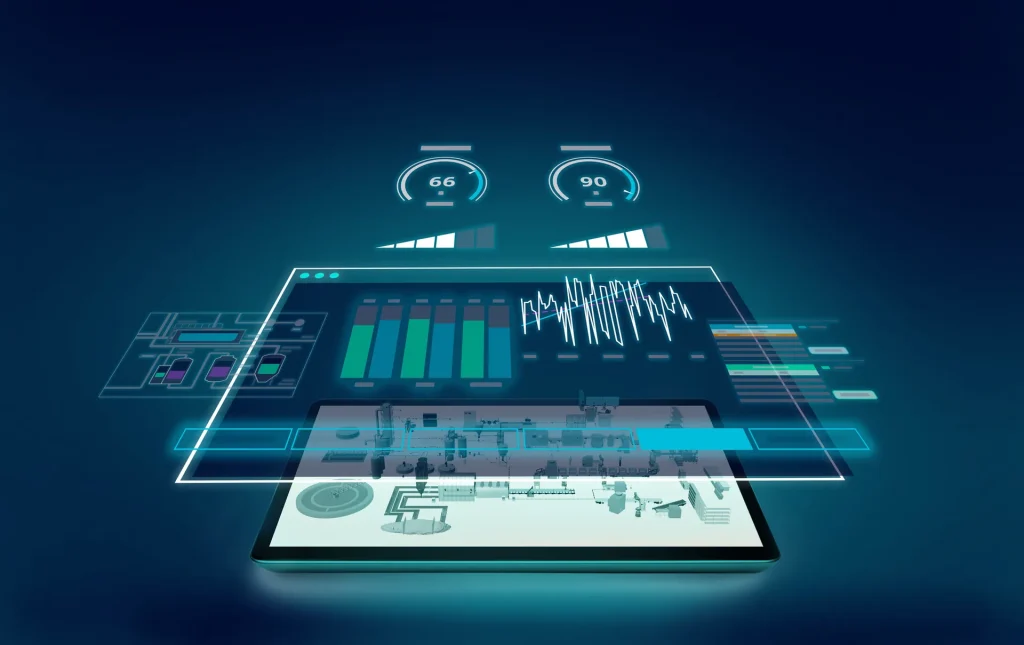

The use of graphical representation and user interfaces to monitor, control, and optimise industrial processes enhances operational efficiency by providing real-time insights into production activities. Through graphical displays, operators can visualise machine statuses, production metrics, and potential issues, allowing for swift decision-making.

Dashboards consolidate data from various sensors and machines, offering a comprehensive overview of the production floor. Trend analysis aids in identifying patterns and optimising workflows, while alarm systems promptly notify operators of deviations or malfunctions.

Moreover, visualisation contributes to a more intuitive understanding of the production process, facilitating training for operators and maintenance personnel. As Industry 4.0 advances, visualisation in factory automation continues to play a pivotal role in achieving smart, connected, and efficient manufacturing environments.

Visualisation hardware

Efficient operator control and monitoring for every application

Operator control and monitoring devices are used in countless applications and in all industries. These rugged, compact panels equipped with numerous interfaces are finely scalable, from simple tasks to high-performance configurations. The comprehensive product portfolio contains the optimal solution for every visualisation task, including for meeting all requirements that go beyond standard applications.

Equipment for monitoring and operator control is needed wherever people have to work with machinery and plant performing all kinds of tasks. SIMATIC HMI Panels are always the first choice when it comes to machine-oriented operation and monitoring.

Visualisation software

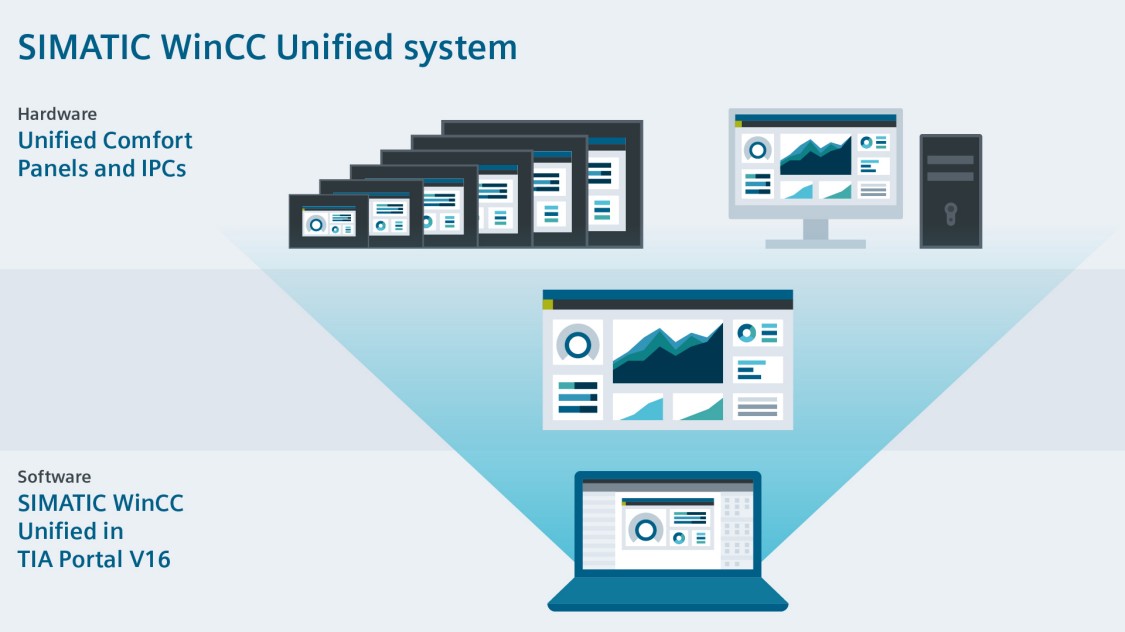

Simultaneously managing huge amounts of data and for monitoring, controlling and continuously optimising complex processes.

Get maximum efficiency in engineering and more flexibility, transparency, and openness, from machine-level visualisation to powerful PC-based systems with Plant Intelligence or distributed SCADA systems.

Whether simple machine-level visualisation, distributed solutions, or complex SCADA systems in production automation and infrastructure applications, the comprehensive range of SIMATIC HMI software for digitalised environments and support for the latest technologies (HTML5, SVG, JavaScript) ensure that you have access to the right system for every application.

HMI products

Software products

Key advantages

Beneficial outcomes of a successful and future-proof visualisation platforms.

Improved operational efficiency

Visualisation allows operators and managers to monitor the factory’s processes, machines, and systems in real-time. By highlighting bottlenecks, underutilised resources, and areas for improvement, this immediate insight can help identify issues, inefficiencies, and potential disruptions as they occur, allowing for timely corrective actions leading to increased production efficiency and resource utilisation.

Better quality control and process optimisation

Visualisation tools can help track product quality and detect defects in real-time, ensuring that only high-quality products are dispatched to customers. By also revealing the areas of the production process that can be fine-tuned or streamlined, improved visualisation can lead to cost savings and better resource allocation.

Enhanced Situational Awareness

Advanced interface enables clear and intuitive representation of the factory’s status, historical data visualisation tools which allows easy analysis of trends, patterns, and historical performance significantly improving situational awareness and decision-making. This can help operators respond to changing conditions effectively for process optimisation and long-term planning.

Shorter engineering time and reduced downtime

Improved visualisation enables promptly identifying maintenance issues that can be addressed proactively, reducing unexpected downtime and costly disruptions to production while saving valuable engineering time.

Enabling sustainability strategies

Improved visualisation enables efficient monitoring of energy consumption and visualising usage patterns helping businesses achieve their sustainability goals.

Increased safety and remote accessibility

Remote access capabilites enable off-site personnel to monitor and control the factory, which can be especially useful for troubleshooting, support and ensure safety for human workforce particularly in unsuitable environment conditions.

Reduced training requirements

Standardised operating concepts, flexibility and user-friendly attributes enable shorter training time and fewer human errors.

Modernisation of Visualisation

Understand the challenges that many businesses face when modernising their systems. Discover the benefits of upgrading now, and the options available. Find out the key features and advantages of the new Siemens WinCC Unified Systems.

Find out more about how we can make future-proofing your visualisation platform easy.

Industries

Food and Beverage

Food and beverage manufacturing utilises visualisation in product design, quality control, and process optimisation enabling compliance with safety standards, enhancing efficiency and quality, and minimising waste.

Automotive

Automotive manufacturing uses visualisation in designing prototypes, simulating assembly processes, and optimising production layouts. It assists in refining assembly line workflows and identifying potential issues, contributing to improved overall manufacturing processes in the automotive industry.

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham is a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.