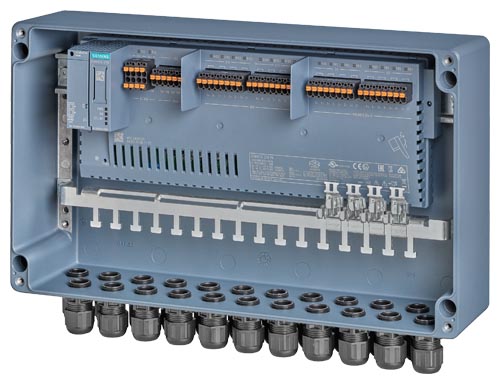

Compact Field Unit (CFU)

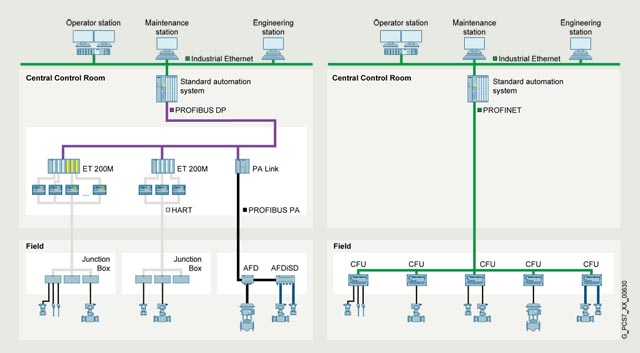

The SIMATIC Compact Field Unit (CFU) is a real game-changer in field device connection and offers you entirely new prospects regarding simplicity and flexibility. The compact field distributor is installed at the process level and is connected via PROFINET directly to the process control system to form the foundation for digitalization in the field. Utilization of digital fieldbus communication simplifies device interfacing considerably compared to conventional 4 - 20 mA engineering.

Smart Field Distributor - SIMATIC Compact Field Unit

With the new SIMATIC Compact Field Unit (CFU), we are re-interpreting the conventional approach to field device connection. The smart field distributor is installed at the process level and is connected via PROFINET, the world’s leading Industrial Ethernet standard, directly to the automation system to form the foundation for digitalisation in the field.

You benefit from greater flexibility and very simple handling coupled with maximum availability. This allows you to efficiently transfer your familiar system concept to the digital world.

Today's challenges for field device connection:

- High overhead for device integration and replacement

- Complicated, error-prone wiring and routing over multiple levels, making the hardware FAT very complex

- Extremely long copper cables and numerous terminal points in the field

- Multiple individual control cabinets

- Large numbers of different components and protocols necessitate costly spare parts inventories and training sessions

- High planning and documentation costs

SIMATIC CFU - The answer to these challenges

Mode of operation

The SIMATIC Compact Field Unit (CFU) is a real game-changer in field device connection and offers you entirely new prospects regarding simplicity, flexibility and standardisation. The smart field distributor is installed at the process level and is connected via PROFINET directly to the automation system to form the foundation for digitalisation in the field. Utilisation of digital fieldbus communication considerably simplifies device interfacing compared to conventional 4 20 mA engineering.

Greater flexibility thanks to consistent decentralisation

Distributed installation of the SIMATIC CFU means that classic control cabinets are no longer required and you can make considerable savings in cabling and the number of terminal points, as well as reducing planning and documentation overheads. The high granularity (16 I/O per SIMATIC CFU) enables flexible assignment to the higher-level controllers.

Function

The SIMATIC CFU was specifically designed to meet the requirements of the process industry in the Industry 4.0 environment (application example: SIMATIC CFU in a standard cast aluminum housing).

System integration via Industrial Ethernet standard

- Flexible connection options via PROFINET

- Ready for Process Automation (PA Ready):

- Redundant PROFINET connection (S2) for maximum availability

- Media redundancy (MRP)

- Configuration in RUN (CiR)

- BusAdapter (electrical, optical or combination)

Ready for distributed use

- Installation up to hazardous zone 2/22 (with conformal housing)

- Extended temperature range from -40 to +70 °C

- Conformal coating use up to 4000 meters altitude

- Implementation of increased interference immunity according to NAMUR NE 21

- Optional: Aluminum enclosure for direct field deployment in zone 2/22

Build innovative machines faster without costly prototyping with Efficient Motion Control.

With Effective Motion Control, machine builders can easily overcome major challenges and enable faster time-to-market, increased functionality, resolve complex system requirements, and demands for safety and sustainability.

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham is a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.