Create pallet patterns for homogenous cuboid products - quickly!

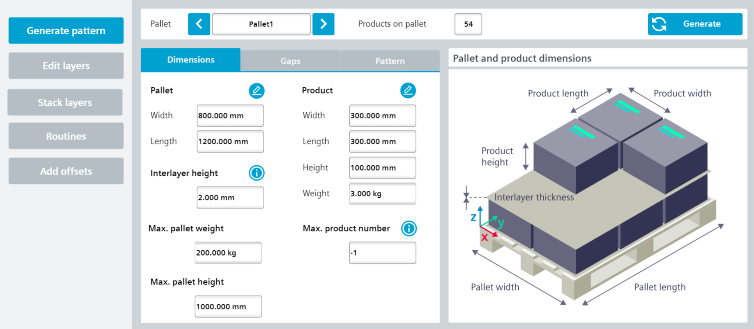

The library LPallPatt (Palletize Pattern Generator) for SIMATIC S7-1500 provides functionalities to create pallet patterns for homogenous cuboid products. Resulting from the pattern generation, a point table is provided that defines the place positions of the products on a pallet, on a slipsheet, or in a container.

Instead of programming, teaching or defining the palletising point table manually, the FB ‘LPallPatt_PatternGenerator’ generates the palletising point table automatically. The automated pattern generation helps to find the best patterns for a high pallet utilisation.

LPallPatt also contains an HMI, which enables the user to carry out the configuration and to check and edit the generated pallet pattern with the integrated visualisation. The image above shows Parameter Input with WinCC Unified.

Key Concepts

Palletizing:

- The process of loading and organising products (boxes, cartons, etc.) onto a pallet in a specific pattern to maximise space utilisation and ensure stability during transportation.

Pattern Generator:

- A tool or function that allows you to define the specific arrangement or layout of items on a pallet. This is particularly useful in automated systems where robots or conveyors are used to stack items according to a predefined pattern.

Benefits

- Flexibility: Easily create and modify palletizing patterns without reprogramming the entire system.

- Efficiency: Reduces downtime by allowing quick changes in palletizing configurations.

- Safety and Stability: Ensures items are stacked in a way that minimizes the risk of toppling during transport.

Example workflow

- Define Patterns: Use the software to define various palletizing patterns based on the dimensions and weight of the products.

- Upload to PLC: Transfer the patterns to the S7-1500 PLC, where they can be selected and executed as needed.

- Automation Execution: The PLC controls the palletizing robot or conveyor to stack products according to the selected pattern.

Use Cases

- Warehouse Automation: Efficiently managing the storage and retrieval of products.

- Manufacturing Lines: Automating the end-of-line process where finished goods are packed and prepared for shipping.

This tool is a part of Siemens’ broader SIMATIC ecosystem, aimed at enhancing industrial automation through modular and customizable solutions.

Discuss Further

If you wish to explore further how Parmley Graham can help with your automation needs, complete your details and we’ll be in touch:

Access Siemens Example

Industrial Automation

To access the Siemens Example, visit :

To browse our products for industrial automation, visit: