Source: www.control.com

A shortage in skilled labour prompted EPLAN to create the new Eplan Smart Mounting software to alleviate manufacturing bottlenecks by efficiently mapping out control cabinets digitally before manufacturing.

Control cabinet manufacturing is not immune to a problem facing automation and manufacturing across the board. Businesses constantly face manufacturing issues due to labour shortages in skilled departments. The problem persists throughout the entire automation industry, including the companies that manufacture automation equipment, such as integrators and control cabinet manufacturers.

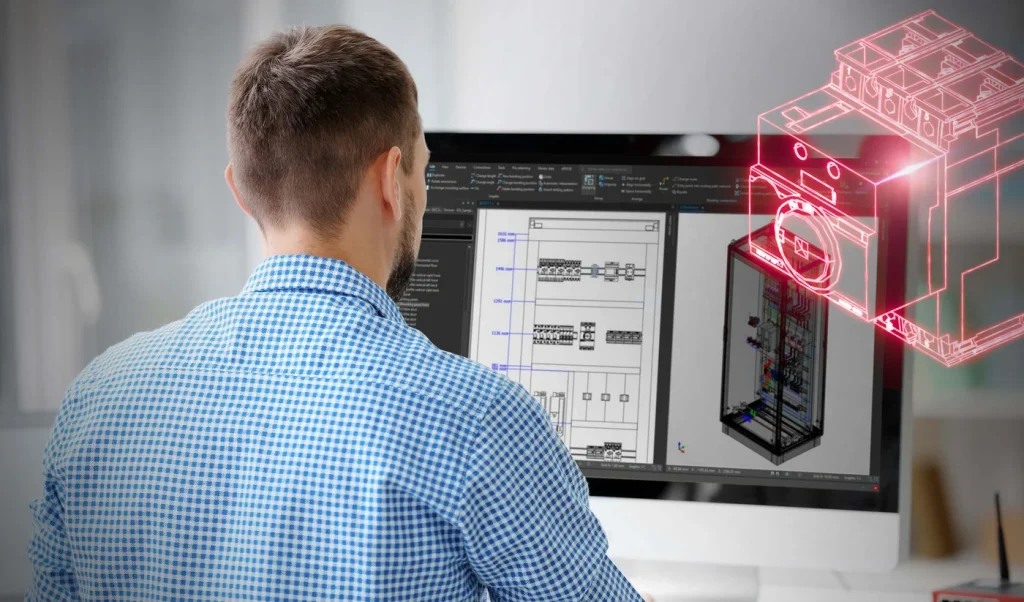

As a result, many manufacturers have looked to artificial intelligence (AI) and other resources to try and help reduce the effect of labour shortages on their production levels. EPLAN has developed software to help extend the effective reach of the current labour available to help manufacturers reduce bottlenecks and missed deadlines. The idea behind the software is to efficiently map out the control cabinet digitally before it is manufactured.

Once the cabinet is mapped digitally, the program can guide workers through building the cabinet most efficiently.

Smart Control Cabinet Manufacturing

Using a digital twin from EPLAN Pro Panel, EPLAN Smart Mounting is designed as an effective way to help speed up the process of cabinet building with reduced labour. The program takes workers through a step-by-step process on how to build the cabinet and where all of the components should be mounted. EPLAN also claims that less skilled labour can be used to work on cabinets with the assistance of the system because less critical thinking is needed to complete the cabinet.

The program includes a 3D visualization to help technicians recognise where parts should be placed, unlike abstract traditional drawings. All of the steps to be taken in the building of the cabinet are mapped out following the proper order the cabinet should be built. For example, the program walks workers through din rail mounting and even shows the right drill locations for the mounting screws. After the din rail is mounted, the Smart Mounting software works through each new procedure to be completed logically.

Live Documentation

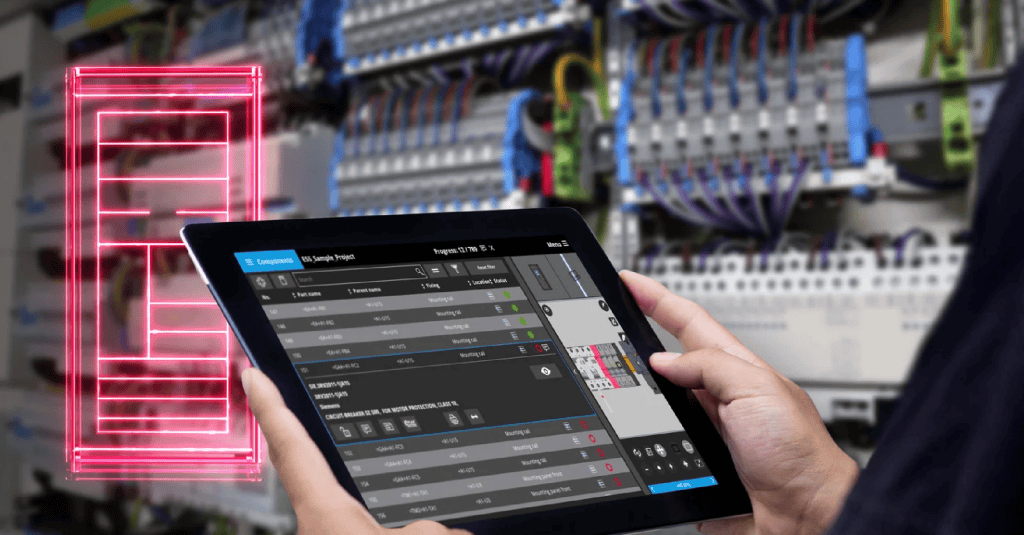

The software is browser-based, meaning no downloads are required – the program can also be viewed on a tablet. The software updates in real-time, allowing technicians to see changes created in the cabinet by the engineering or management department. Technicians can also add comments to certain components for the engineering department to see.

With constant updates in real-time, technicians and the engineering department can always see an up-to-date version of the control cabinet progress and any documentation changes. This helps to reduce inefficiencies or mistakes caused by out-of-date drawings accidentally in circulation. It also promotes and improves communication between departments since everyone is looking at the same live documentation.

Manual comparisons of documents become a thing of the past in cases where specifications change. Any change, including different-sized components, or the addition or deletion of components, is easily transferred and updated across the platform. The software will then display to the technician which components need changing and where they are located.

Cabinet Cabling and Wiring

Data from EPLAN’s digital twinning software, Pro Panel, can also be used in the cabling process once all of the components are correctly mounted as part of EPLAN Smart Wiring to prefabricate wires helping to streamline the process for a more efficient result. EPLAN’s software is compatible with the Rittal Wire Terminal WT to create fully automatic wire assemblies.

Design Software Solutions

As a world leader in design software solutions, EPLAN hopes its latest software will help ensure efficiency and quality from the engineering face to the manufacturing face of cabinet manufacturing.

Discuss Further

About Rittal

Our partner Rittal is the world’s leading systems provider for enclosures, power distribution, climate control, IT infrastructure, and software

Explore the Rittal product portfolio

For more information, visit the Rittal website.