Sustainability

Sustainability and energy efficiency in production

Energy costs are high, resources are becoming scarcer, and climate change laws and regulations are constantly expanding. How can industrial enterprises today maintain their competitive edge and embrace sustainability as an opportunity? By implementing solutions that combine data transparency with very specific recommendations for action – from production to the supply chain.

Find out more about our Sustainability solutions, speak with our experts.

Overview

Make your company more sustainable and energy-efficient.

Your path to improved sustainability and energy efficiency.

A comprehensive approach to a sustainable transformation helps you prepare for the future. First of all, you need an overview of your resources. Then you can use data to define key performance indicators (KPIs) and find ways to make improvements. Combine this with solutions that efficiently manage and optimise consumption in order to guarantee the flexible use of resources and save money. Finally, you have to be able to safeguard and verify the decarbonisation of infrastructure, processes, and products.

Resource transparency

Resource efficiency

Thanks to resource-efficient production, you can correlate different data with external influences: for example, using energy forecasting, which generates meaningful energy performance indicators from raw data to predict future consumption. This allows you to analyze the factors influencing power consumption.

Another example is tracking measures that document the resulting costs and improvements – while at the same time reducing the number of tools needed for this task. Ever-stricter regulatory requirements and audits for certificates like ISO 50001 demand both transparency and traceability if there’s to be continuous improvement.

Resource flexibility

Flexible resource management can ensure a fast response to rapidly changing customer and environmental requirements: for example, load peak management that helps you reduce energy costs. By preventing peak loads, you’ll also reduce the fines that you’d potentially pay to your power company.

The flexible deployment of generator sets also contributes to optimising your plant’s power consumption. When you use self-generated energy and accurately plan your consumption, you’ll need less power from the grid. When the generator sets are automatically switched on and off, you can also reduce the actual power limit.

Key advantages

Benefit from sustainability and energy efficiency in production.

Transparency

Compliance

Comparability

A user-friendly analysis of standardised measured values lets operators compare their machines’ performance with the effectiveness of energy-efficiency measures and continuously optimise both.

Flexibility

For your specific requirements, talk to us.

To see how we can help with your systems or if you have any enquiry, please get in touch – we’ll be pleased to help. Send us an email at support@parmley-graham.co.uk or fill the form below.

Collaborative emission management

SiGREEN: A dynamic, data-driven and scalable innovation to manage and reduce emission along the entire value chain.

Better data – better decisions

Current PCF management tools use averaging methods to calculate emissions and this only provides static information. With SiGREEN, you can quantify emissions as they occur on-site and aggregate them along the entire value chain. The result is a dynamic PCF that helps you make data-driven decisions for impactful reduction measures. Let’s turn emissions data into a powerful tool for sustainably decarbonising your products.

Dynamic data

Data sovereignty

Verifiable results

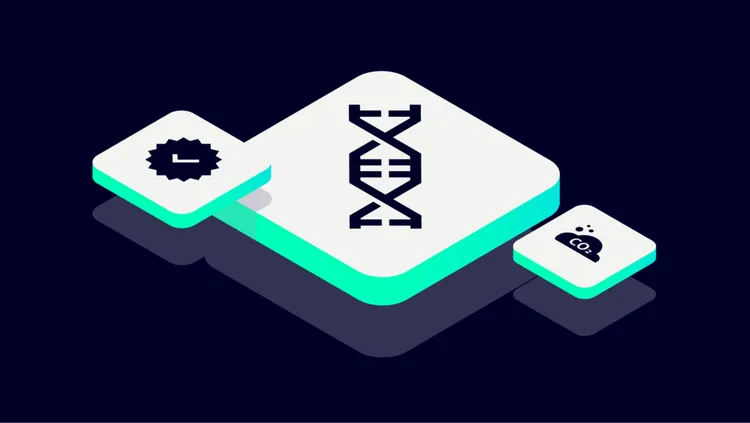

Decoding your product’s carbon DNA

The SiGREEN principle

Made to scale: Stand-alone or fully integrated

A paradigm shift: Dynamic Product Carbon Footprints

Companies need a substantial foundation for making data-driven decisions about appropriate decarbonisation measures. Static industry averages are insufficient. Instead, dynamic, constantly updated data is needed that can only be collected in a direct exchange between companies along the entire supply chain. With SiGREEN, suppliers can proactively and promptly communicate actual emission values and transmit the results of optimisation approaches.

Industry applications

Chemical manufacturing

Approaches for emission reduction

SiGREEN features

- The development of an adaptable PCF reduction roadmap and vendor agnostic implementation

- Technological transparency of the emissions from your processes

- A deep understanding of your process and the identification of optimisation potentials that will reduce the CO2 footprint

- Well-founded concepts for technological transformation based on your specific processes and framework conditions, including intelligent integration and use of renewable energies

- Prioritised list of measures for future decision-making, plus along with implementation support on a broad technological basis

Automotive

Low PCFs as a competitive advantage

Requirements of the Catena-X ecosystem

SiGREEN solution

- Data exchange along the supply chain

- Systematic reduction of emissions in the upstream supply chain

- For free and as software as a service with easy onboarding of SME

- Open APIs for connecting and using data in other IT systems

- Siemens as a strong, reliable industry expert offering Digital Product Passport solutions

Electronics

Proactive improvement updates

In the electronics industry, more than 90% of PCFs are generated in the supply chain before they reach the factory floor. Compared to other industries, the number of delivered parts and suppliers is high. There are usually multiple procurement channels for the same components, while technologies and specifications are constantly changing, especially when new features need to be integrated. In addition, more and more distributors are requiring PCF data before products are included in their offering.

Approaches for emissions reduction

SiGREEN features

- Transparency regarding PCF in the event of product design changes and the introduction of more environmentally friendly energy generation

- Potential analysis of emission reduction in the supply chain

- PCF with one click for constantly changing specifications

Food and beverage

Sustainable food for a healthier tomorrow

Integration of customers and suppliers

SiGREEN features

- Enhanced brand reputation thanks to greater transparency for customers who value sustainability

- Supply chain optimisation by identifying inefficiencies and reduction of waste at every stage of the process

- Regulatory compliance, avoidance of penalties, and cost reductions when carbon taxes are introduced

Battery manufacturing

Verifiable PCF data for the battery passport

Integration of customers and suppliers

Battery manufacturers need solutions for declaring their products’ emissions on a large scale and transferring them to a digital battery passport. The majority of emissions is usually generated in the supply chain, and this information needs to be systematically shared and managed. To meet CO2 targets, emissions must be optimised not just in production but also across the entire supply chain. This requires reliable and trustworthy information from all suppliers.

SiGREEN features

- Automated calculation of PCF and provision via APIs to a battery passport

- Exchange of certified and verifiable PCF data along the supply chain

- Systematic management and optimisation of carbon emissions in the supply chain with data from the suppliers

- Reduction of internal emissions using technology from related Siemens portfolios like Energy Manager PRO

Use of emissions data by other ESG tools

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham are a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.