Efficient Motion Control

Siemens provides a unique engineering framework for easy motion control and the integration of kinematics solutions.

Faster time-to-market, increasing functionality and complexity, and demands for safety and sustainability are major challenges for machine builders. Efficient motion control helps you build innovative machines faster and without costly prototyping, so you can more easily meet your customers’ needs.

Find out more about our Motion Control solutions, speak with our experts.

Overview

Efficient Motion Control - time for other perspectives!

Industry is demanding more and more complex motion control solutions and robots. To meet these demands, machine builders must compensate the shortage of skilled workers, become more flexible in the face of increasing complexity, and ensure the safety of operators and machines. But how?

With solutions for efficient motion control – turn challenges into success!

Increase your flexibility

Increase your flexibility in motion control projects with modular, standardised, and user-friendly engineering and operation.

Speed

Accelerate the time to market of your machines through parallelisation and virtualisation of work routines.

Sustainability

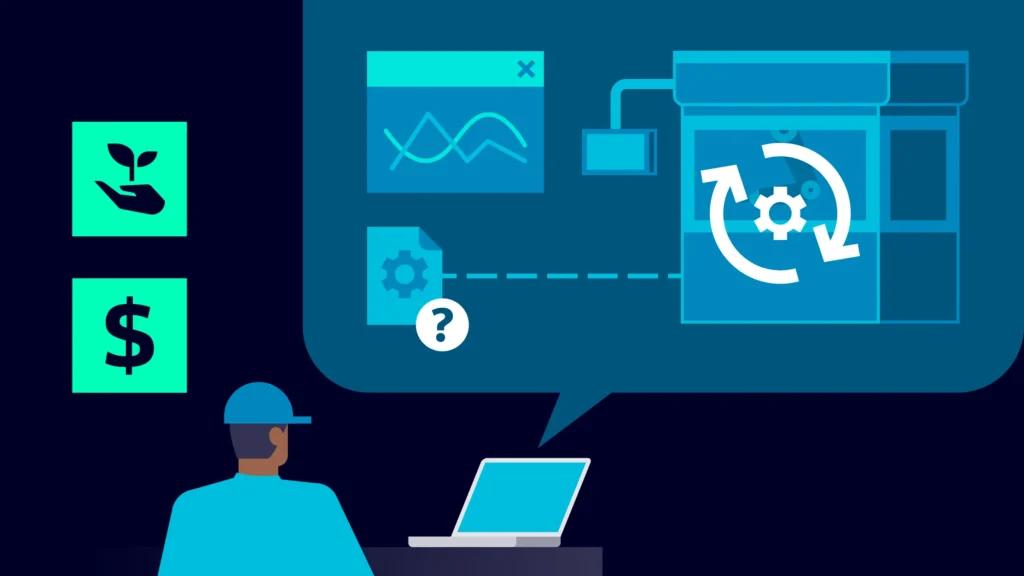

Test and validate applications in a virtual environment without hardware or physical prototypes.

Safety

Ensure maximum machine and operator safety while maintaining productivity and flexibility.

Industry challenges

Understanding and overcoming technological, organisational and operational challenges.

A shortage of skilled workforce, time and innovation pressures, and stringent safety requirements are challenging machine builders. With robots becoming increasingly important in industry and driving demand for innovative motion control solutions, can you reliably meet these demands quickly and safely?

Imagine…

Megatrends impacting machine builders

Time to Market

Establish efficient processes that enable parallel engineering, simulation and testing.

To bring new machines to the market faster, OEMs must establish efficient processes that enable parallel engineering, simulation and testing solutions, including motion control.

Digitalisation and virtualisation are key in this respect. Moreover, machines and solutions must be commissioned as quickly and efficiently as possible, both during the initial setup and following modifications and revamps. One critical aspect in this regard is the integration of kinematics systems, where OEMs need to find flexible solutions that reduce the time and effort spent.

Safety

The rising level of complexity and the demand for highly productive and high-speed production may come at an increased risk for both equipment and operator safety. With the available space in the production environment becoming an increasingly valuable commodity, machines need to be equipped with safety systems that ensure maximum protection for machines and operators yet are compact and can be set up efficiently.

To avoid unnecessary downtime, safety systems need to be able to selectively shut down machine parts, support more advanced safety functions such as limiting the machine speed and allow for easy modification and integration of machines and lines – all in full compliance with increasingly strict legislation and regulation.

Lack of skilled staff to fulfil the increasing level of automation

Flexible & Profitable Machine Concepts

Efficient Motion Control

Helps you build innovative machines faster and without costly prototyping, so you can more easily meet your customers' needs.

SIMATIC Motion Control – simply more for you!

SIMATIC Motion Control is the simple solution to sophisticated challenges in the motion control of modern machines or plants. Siemens’ flexibly scalable automation solutions with seamlessly integrated safety functions and efficient engineering in TIA Portal allow you to quickly implement your innovative machines and plants.

Ways to make Motion Control more efficient.

In motion control, technologies operating on multiple different axes can be coordinated at the same time to move loads to specific positions at specific times, saving precious minutes in production time. Single and coordinated axes can be found in applications such as mixers, conveyors, indexing flying sheers, rotary knife, and palletising, to name a few.

Axes offer flexibility and versatility in motion range and control, making them a key part of many production lines. With the global market for motion control rising rapidly – with one report predicting that the industry will see a CAGR of 5.5% by 2026 – it is more important than ever to optimise the use of single and coordinated axes to maximise productivity.

Why is Motion Control sometimes difficult?

The market for single and coordinated axes is far from simple as there are multiple different motion control system components and solutions available in the industry, which can make optimisation challenging, and implementing solutions risky and costly. As a result, building a production line efficiently, where different systems work together, can be extremely difficult.

Machine builders are always being challenged to modernise machine concepts and realise new production approaches to meet the demand of industry, with batch sizes of one and consumer demand for individualisation and a faster time delivery. However, it can be difficult to imagine and program complex movements. Sophisticated motion often requires specialist technology and specialist knowledge – for example, it can be difficult to realise more intricate movements between coordinated axes without simulation – which can be complicated and time-consuming for engineers without the right tools.

The trick is to look for a seamlessly integrated motion control solution that can simplify build, engineering, and execution.

Easy control of single axes

How to implement continuous and cyclic motion and realise a complete and seamless motion control solution for your specific requirements?

Imagine you must realise new machine concepts or modernise existing ones in terms of flexibility, efficiency, and future viability. There are different motion control system components or solutions available, and the engineering of motion control components and solutions is quite complex.

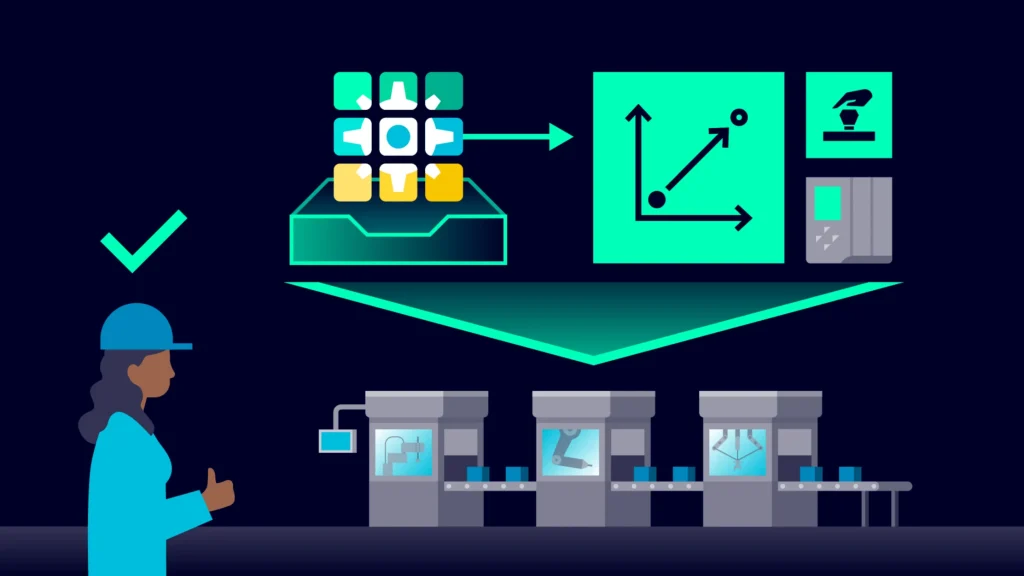

The key factor is to simplify your application. Siemens’ integrated motion control system solution with one easy and intuitive engineering tool accelerates development time. The scalable hardware portfolio (controller, drives, motors, HMI, I/Os, and communication) includes optional safety functionality and allows fast and simple drive and motion control integration and configuration.

Easy control of coordinated axes

Can complex coordinated motion in production machines be simplified?

The complex movements between coordinated axes are difficult to imagine and program without visualisation and simulation capabilities.

Standard application examples based on technology objects help you simplify complex axis relationships. We help you efficiently configure and program complex motion control applications with system-integrated editors for configuring individual dependencies between coordinated axes. All this can be done in a single familiar programming environment.

Easy control of kinematics

How do you integrate and manage standardised and customised system-integrated robot mechanics with up to 6 interpolated axes?

You need to visualise and program complex kinematic motions in 3D Cartesian space and develop standardised safety solutions for machine and operator protection.

Use custom and predefined transformations with technology objects for your standard programming. Implement and operate easy and fast robots and custom kinematics for repetitive handling tasks in a production machine or line. Control and use robots, machine automation and safety solutions that monitor kinematic movements in the 3D Cartesian space in one controller.

Easy robot integration

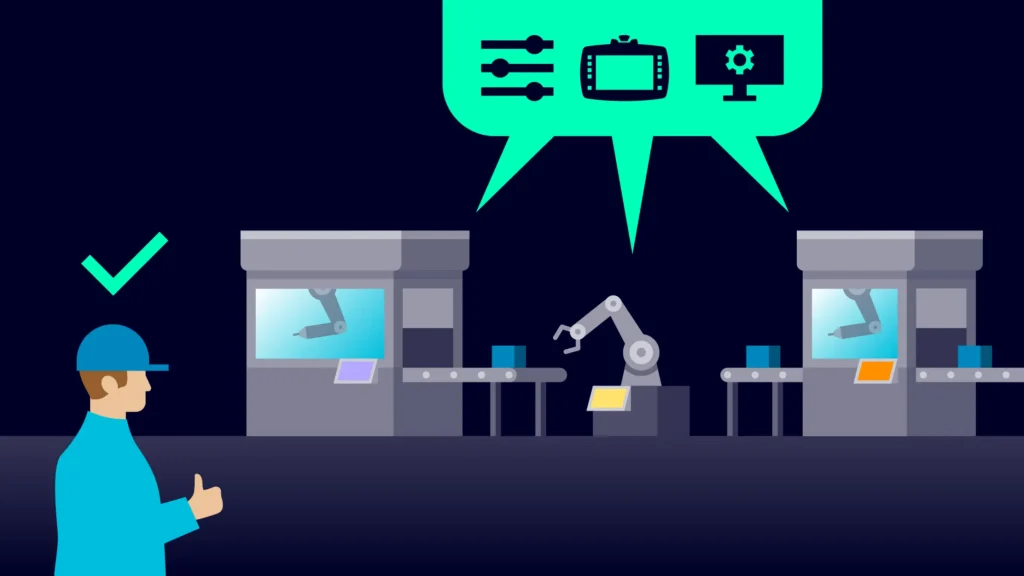

How do you manage multi-vendor robots in your automation environment?

Engineering is challenging due to complex robot systems (HMI, controller, and engineering tools) that differ from manufacturer to manufacturer. What’s more, there is a lack of experienced robot specialists and a lack of standard interfaces for integrating robot systems into the automation system.

Better use a standardised engineering language for your robot application to simplify and standardise robot engineering and operation. Our solutions provide a unified interface between robots from any vendor and the machine PLC, handling robots and automation in a single engineering framework.

Easy simulation of Motion Control applications

How do you test and simulate your production machine in a virtual environment?

Typically, you need prototypes and hardware to validate and optimise motion control applications. Errors can cause damage and be costly.

By using simulation, you can reduce material damage and waste, become more sustainable, and make complex motion visible and easier to understand. No real hardware is required. We support you with simulation software and integrated testing capabilities within the engineering framework. You can test based on an emulated PLC with open interfaces to co-simulation tools for electrical and mechanical behaviour.

Key advantages

Benefits of an integrated Motion Control solution

An integrated motion control solution provides efficient engineering by consolidating motion control into one single standardised engineering platform – the Totally Integrated Automation (TIA) Portal.

Benefits of this approach include:

Flexibility

Easy and fast adjustment of your application towards higher motion control requirements regarding function and performance.

Standardisation

A fast start open protocols and programming blocks, wrapped up with ready-to-use application examples, enabling a simplified set-up for your specific application requirements. Using standard application examples can help to simplify complex motion and axes relations.

Efficiency

A seamless integrated motion control system solution in one engineering tool naturally provides engineering efficiency.

Scalability

Integrated motion control systems offer comprehensive and flexible options for full customisation and scalability, including fully integrated safety functionality and diagnostics.

Intuitive Design

Simplify motion control task engineering thanks to integrated technology objects and an intuitive operation with guided user interfaces (GUI).

Ultimately, customers that use system-integrated motion control solutions stand to gain greater flexibility and faster time-to-market by investing in a centralised way of managing multi-axes motion.

What does efficient control of single and coordinated axes look like?

A streamlined, efficient, end-to-end solution is key for simplifying production. With so many components and solutions available, it can be easy to add complexity to your operations without needing to.

Siemens motion control provides a single, flexible, and standardised solution for single and coordinated axes management.

Its scalable motion control hardware portfolio, with fully integrated safety functions, including controller, communication, drives and motors, provides one single platform which supports a standardised and efficient environment for engineering.

Technology objects for motion control are integrated in every Siemens PLC to deliver comprehensive engineering functionality. This includes gearing and camming axes (with intuitive guided graphical user interfaces); cam editor to intuitively program relations between leading and following axes; and trace for the diagnosis of application behaviour. And, with predefined standard application examples to help configure axes and simplify axes relations, it’s incredibly easy to get up and running – as well as to adjust the system to meet your requirements.

This functionality is delivered through the TIA Portal – an easy-to-use, single engineering tool for all automation, motion control, and safety tasks.

The result is an efficient, seamless, end-to-end solution for single and coordinated axes engineering and management. The combination of complete flexibility with predefined structure and control means that even the most complex motion requirements can be easily configured, adjusted, and monitored without the headache of multi-vendor engineering platforms or needing to invest in additional specialist tools or engineering expertise.

For your specific requirements, talk to us.

To see how we can help with your systems or if you have any enquiry, please get in touch – we’ll be pleased to help. Send us an email at support@parmley-graham.co.uk or fill the form below.

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham are a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.