Industrial Automation

Enhancing efficiency, productivity and precision in manufacturing and other industrial operations.

The use of control systems, such as computers or robots, for handling different processes and machinery in an industry to replace human intervention has transformed manufacturing and production processes across various sectors.

At Parmley Graham, we bring our expertise together with high caliber automation products from top OEMs worldwide to develop innovative, single-source solutions for various industries.

Browse our products below or let us hear about your requirements. Contact us to speak with our experts.

Overview

Increased efficiency, improved quality, and enhanced safety in manufacturing and production environments.

The primary goal of industrial automation is to enhance efficiency, productivity, and precision in manufacturing and other industrial activities. It involves the integration of hardware and software components to control and monitor various processes, including machinery, processes, factories, boilers, and heat treating ovens.

As technology advances, concepts like Industry 4.0 are emerging, emphasising the integration of the Internet of Things (IoT), artificial intelligence, and big data analytics into industrial automation. This evolution promises even greater levels of connectivity, data-driven decision-making, and adaptability in manufacturing processes, paving the way for a more intelligent and responsive industrial landscape.

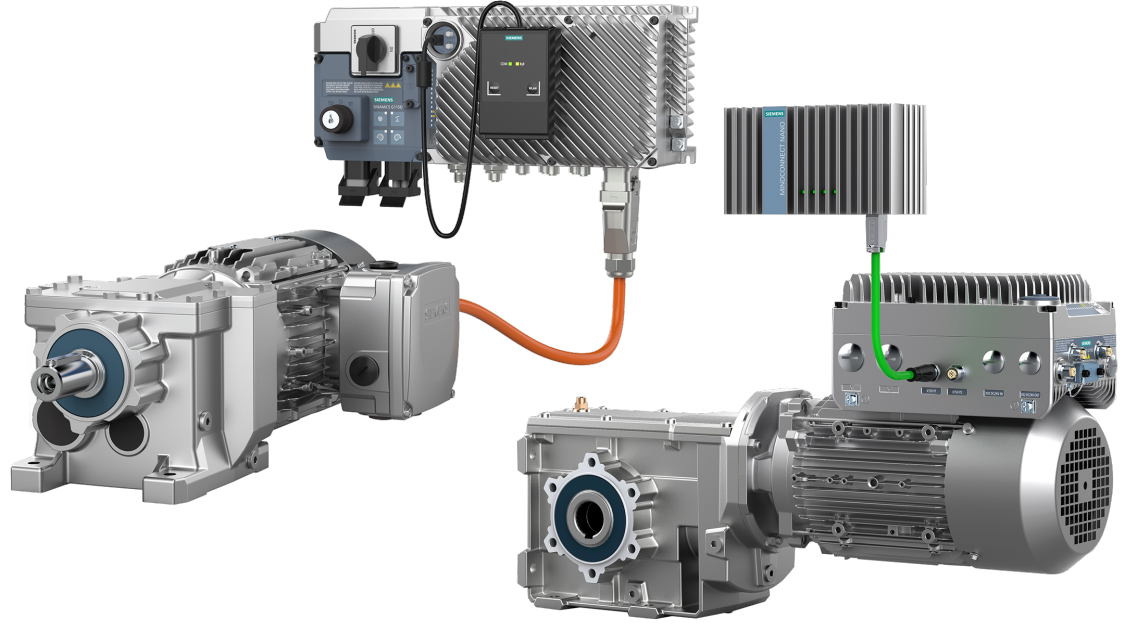

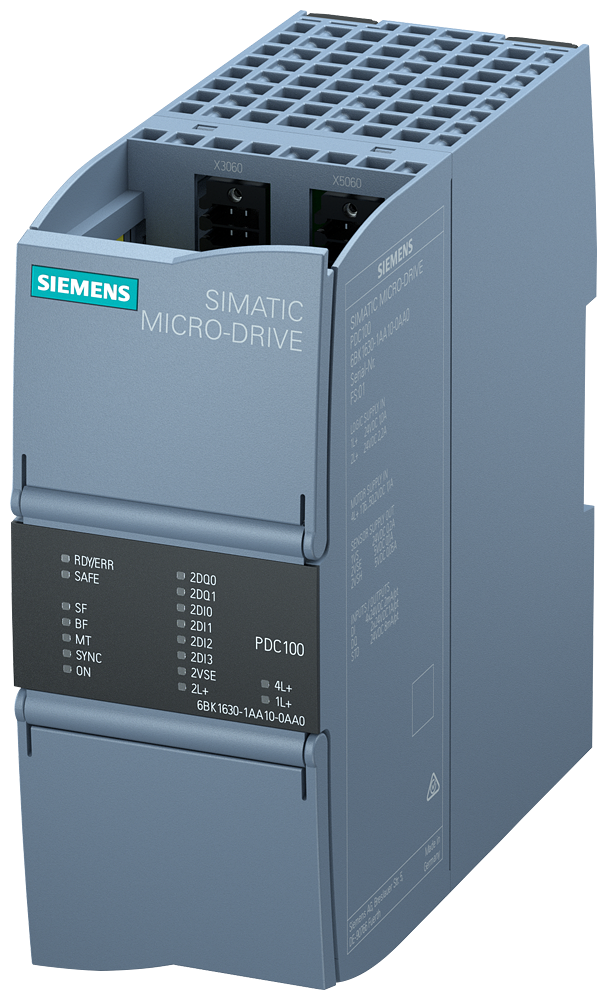

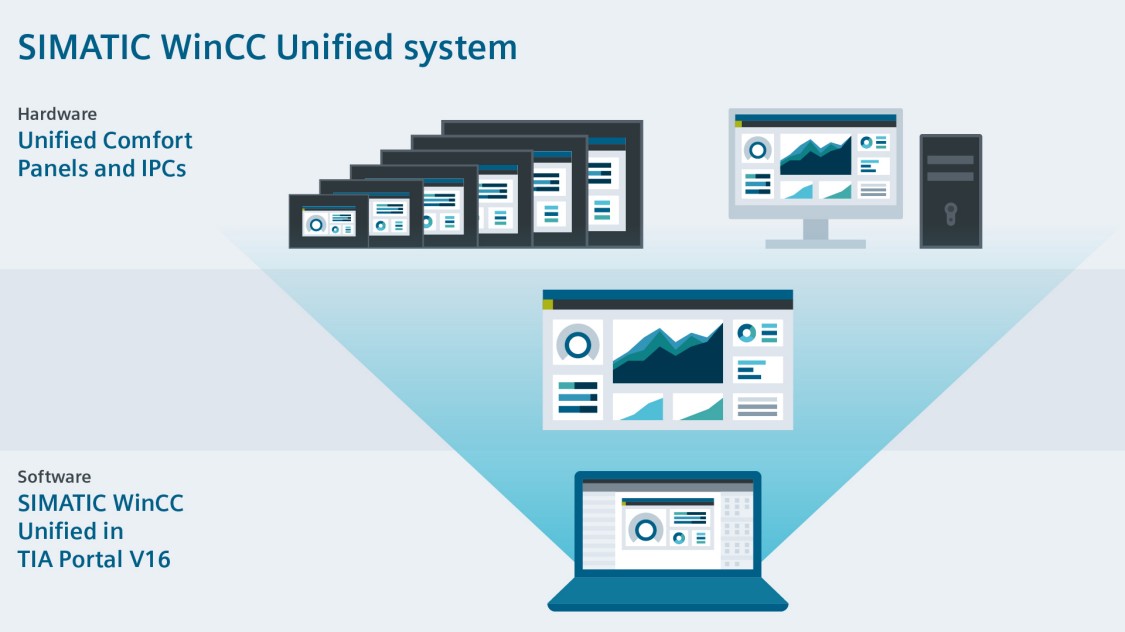

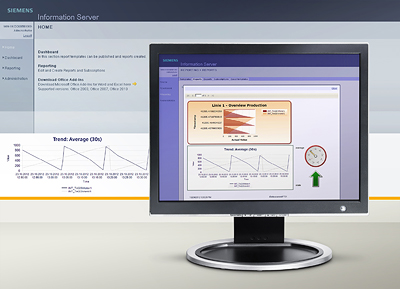

Key components of Automation

These components work together cohesively to automate and optimise various industrial processes, leading to increased efficiency, improved quality, and enhanced safety in manufacturing and production environments.

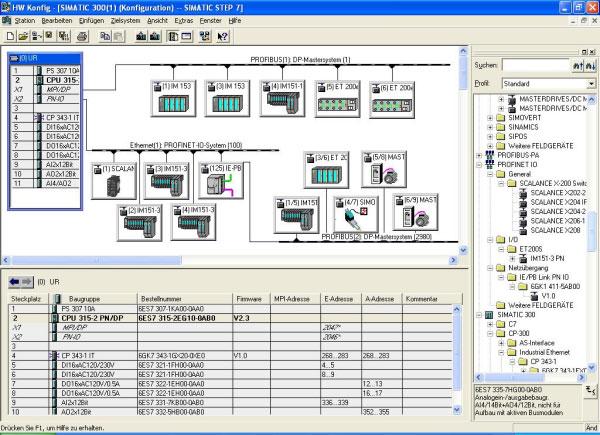

Programmable Logic Controllers (PLCs)

Communication Networks

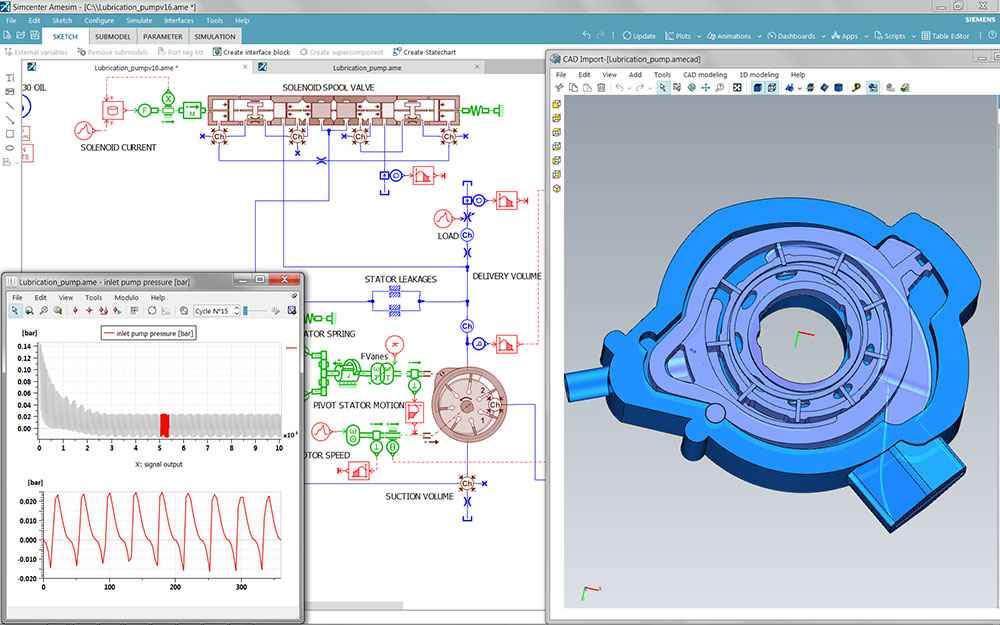

Industrial Software

Industrial Edge

Virtual Commissioning

Key Benefits

Revolutionising the traditional manufacturing and production paradigms, for a more innovative, competitive, and sustainable industrial landscape.

Industrial automation transformative impact on efficiency, productivity, and precision across diverse industries enables increased production capacity, improved product quality, and a safer working environment. Moreover, automation fosters adaptability and flexibility in responding to changing demands, while continuous advancements, including Industry 4.0 principles, promise even greater connectivity and intelligent decision-making in industrial settings.

Increased efficiency

Cost Reduction

Enhanced product quality

Automated systems offer precision and consistency in manufacturing processes, resulting in higher product quality and reduced variability. This consistency contributes to fewer defects and improved adherence to quality standards.

Improved safety

Continuous operation 24/7

Automated systems can operate continuously without the need for breaks or shifts, leading to increased production output and the ability to meet high-demand scenarios more effectively

Increased flexibility and adaptability

Data collection and analysis

Faster time-to-market

Increased production capacity

Manpower allocation for higher-value tasks

Regulatory compliance

Industries

Automation is applied in industries such as automotive, pharmaceuticals, food and beverage, aerospace, and many more.

Food and Beverage

Automotive

Automation is an important process in Automotive manufacturing enabling increased efficiency, precision and overall production from assembly, material handling, welding and joining – to painting, finishing, quality control and more.

Pharmaceuticals

From screening, bioprocessing, quality control and testing, packaging and serialisation, warehouse and inventory management, to data management and analysis – automation plays a crucial role in enabling efficiency, accuracy and compliance in pharmaceutical and life science sectors.

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham are a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.