Panel Building

Enabling the easy way to the optimal control panels.

Our wide range of topics for control panel building not only include standards, EMC, heating and retrofitting. It also contains supplementary background information on electrical planning with tools and data. Depending on your needs, speak with our experts for in-depth topics and further assistance.

Overview

Helping accelerate your business process in control panel building.

Solution

Enabling solutions for your challenges in control panel building.

Standardisation: Reducing overall costs with standardisation of electrical equipment of machines

When procuring plant equipment, plant operators rely on standards, guidelines, and legal requirements for the protection of their people and plant equipment. Manufacturers of electrical equipment, however, have leeway for interpretation when observing these requirements, which can create a great deal of coordination work. It’s better to use a technical specification.

Standardisation and the development of operator specifications can require significant work initially, but this effort pays for itself many times over – from the beginning of machine development and throughout the entire lifecycle.

Huge potential for savings on operating costs!

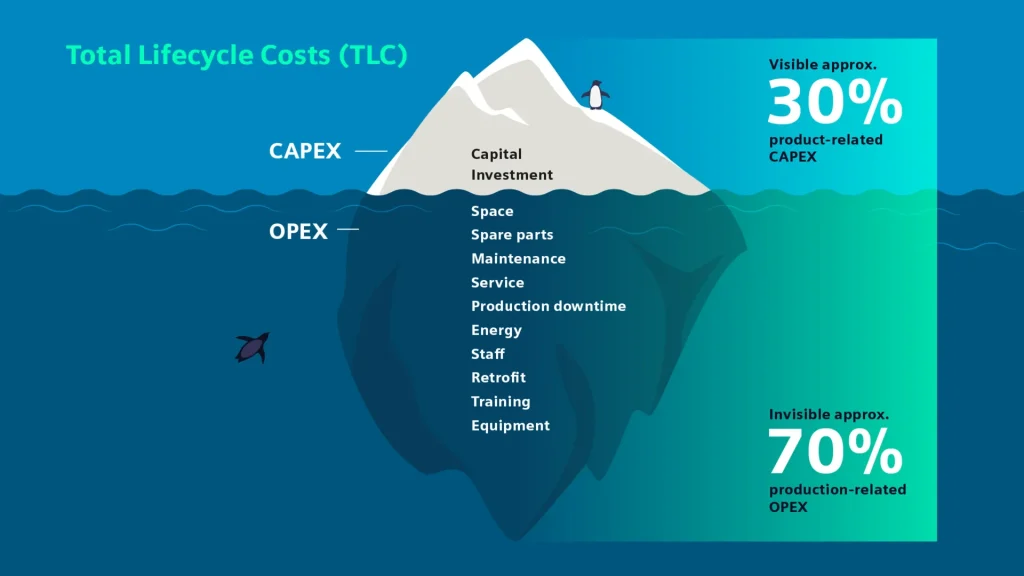

If you look only at the procurement costs (CAPEX), you can miss the huge potential offered by standardization. High operating costs (OPEX) are incurred throughout a machine’s lifecycle, for example during downtimes, or inventory costs for spare parts, support, maintenance, etc. Standardisation can help plant operators reduce these costs and thus save money over the long term despite the high up-front costs.

Precise operator specifications mean manufacturers can work more efficiently because there is less need for coordination and they have the opportunity to re-use successfully tested projects for new orders. We support both operators and manufacturers with our experience in drawing up operator specifications and in implementing them properly.

Cost savings in practice

Although a standardisation strategy leads to higher initial costs (initial investment by the machine supplier), this is followed by significant potential savings throughout the service life of the machines.

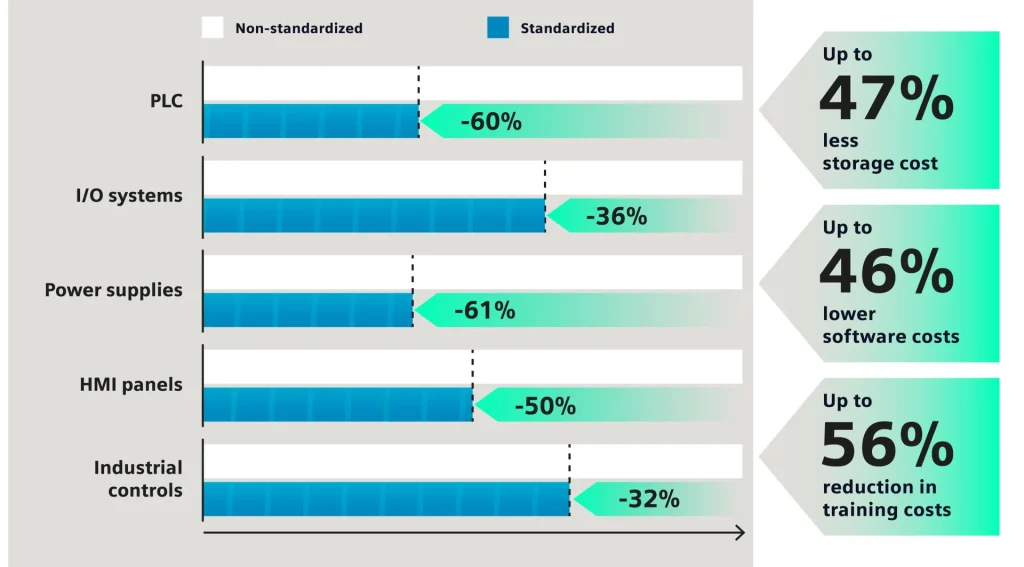

Comparing projects with and without standardisation in the graphic at right shows that inventory costs are reduced by up to 47 percent, software costs for engineering by up to 46 percent, and the number of suppliers by up to 56 percent, which also reduces overall training requirements (see sample calculation).

If the systems are always acquired from the same machine supplier, that should also reduce the machine manufacturing cost, since standardization can result in shorter commissioning times, for example. Standardization of electrical equipment also gives new machine suppliers a clear model to build on.

Key Benefits

For manufacturers

Clear requirements for everyone involved

Efficient planning and engineering

Smooth acceptance

Clear requirements through standardisation result in significantly fewer objections during the acceptance process and thus fewer complaints.

This helps avoid missed deadlines and the risk of contractual penalties. It also makes acceptance by listed centers or testing labs (e.g. UL, CSA) easier.

For operators

Reduced downtime costs

Short circuits, constant high temperatures, undue heating or EMC stresses will significantly increase the risk of unplanned downtimes. Standardisation minimises the risk of downtimes and increases both maximum service life and availability.

Easy power monitoring

Insufficient standardisation can make power monitoring a labor-intensive activity in terms of compatibility between software and hardware from multiple vendors. Standardisation lets you easily integrate measuring devices or power monitoring software from different vendors for data management, for example.

Predictive maintenance

Condition monitoring creates the basis for predictive maintenance.

Prescribing the appropriate components can limit version proliferation. Standardisation with Siemens reduces complexity and maintenance costs.

Find out more about Predictive Maintenance.

Smaller footprint

The various product solutions for application requirements when it comes to designing a control panel involve very different footprints. Standardisation limits this variation and can even optimise it thanks to the use of space-saving components. In addition, standardised rules for construction help make the best possible use of the available space.

Reduced use of materials

Standardisation is a way to prescribe the use of particular products that offer other functions beyond their immediate purpose, such as the SIRIUS 3RM motor starter or the SENTRON 3VA with a measurement function. As a result, you need fewer components for additional functions.

Lower inventory costs

For your specific requirements, talk to us.

To see how we can help with your systems or if you have any enquiry, please get in touch – we’ll be pleased to help. Send us an email at support@parmley-graham.co.uk or fill the form below.

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham are a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.