The National Collection of Aerial Photography

Using collaborative robots (cobots) to automate the digitising process of scanning millions of historical images, The National Collection of Aerial Photography (NCAP), part of Historic Environment Scotland, holds millions of images in need of digitising.

Understand how Parmley Graham helped them automate this process using collaborative robots.

Automating photo scanning process using cobots

The challenge

Identifying the solution

Identifying their needs

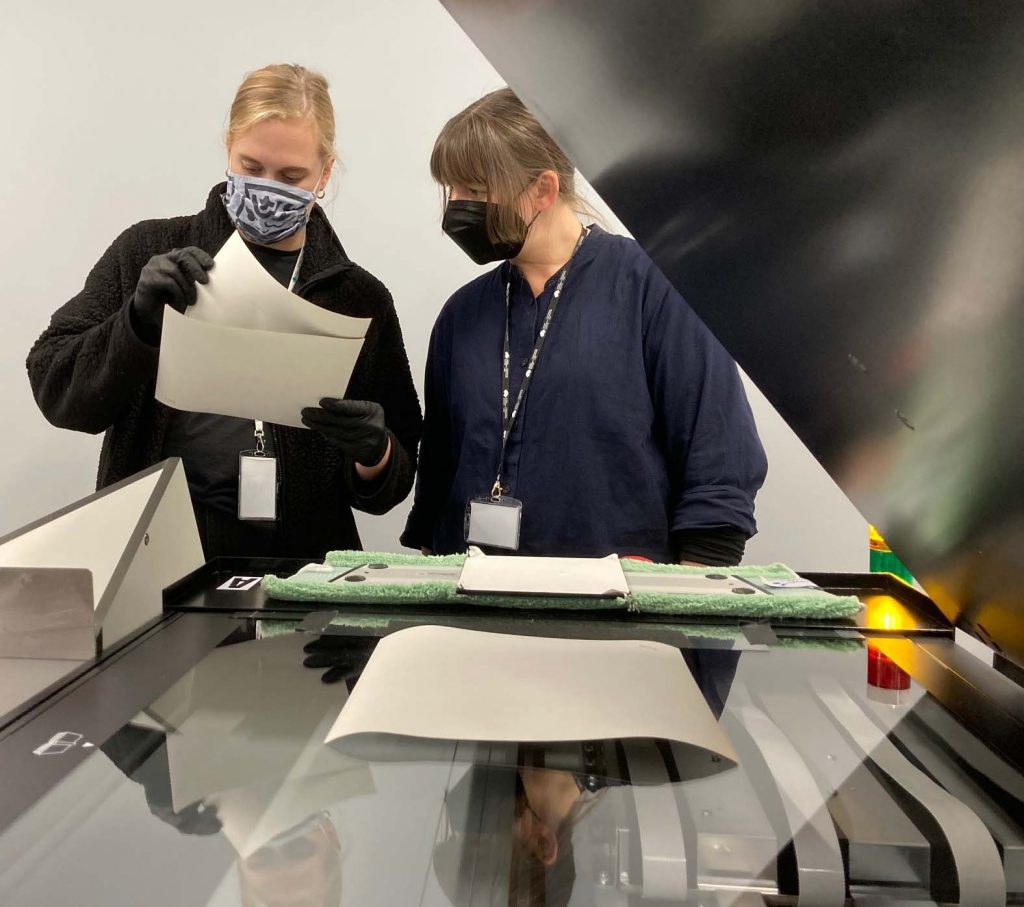

Analysing scans

Training Sawyer Cobot to pick

Training the team

Positioning Cobot Arm

Cleanroom facility with Sawyer Cobots in place

The results

The solution proposed involves robots supplied by Parmley Graham, or to be precise, collaborative robots (cobots); so named because they interact alongside humans.

Manufactured by our partner Rethink Robotics, cobot Sawyer, with its friendly face, is quickly accepted by the human workforce thanks to its design. Sawyer is delivered as an out-of-the-box cobot solution, equipped with powerful software and integrated camera systems. The Intera software platform has a graphical user interface that lets users train the robot, even if they have never written a line of code or programmed a robot before. using the industry-leading train-by-demonstration capabilities of Intera, anyone can interact directly with the robot’s arm to easily train new tasks.

Yorkshire-based CBM Logix engineered an integration system that uses the cobot arm to lift prints from the in-tray, place them on the scanners, and operate the scanners before carefully placing the scanned prints in the out tray.

Parmley Graham worked closely with CBM Logix to help deploy the five Sawyers and other automation requirements including the installation and testing of the PLC controller.

A team of eight humans and 5 cobots are currently preserving and digitising imagery of the commonwealth countries in a new, purpose-built facility in Edinburgh. Each of the five cobots has its own scanning cell housed within a dedicated cleanroom from where over 5000 prints a day are being scanned – far more than five humans could achieve.

From the initial concept, this project has grown into a fully functional, fully automated, and well-engineered solution. Impressively, the operation is geared for a 24/7, true ‘lights-out’ operation. A whole work cell, including the Sawyer cobot, two scanners, two PC’s, the PLC control cabinet and the silent compressor consumes an economical 2.4kwh – less than your average kettle!

Enabling enhanced efficiency, quality and safety for Food and Beverage operations.

Discover our solutions as key enabler for efficient, excellent quality, and highly competitive operation, allowing our clients effortlessly meet the demands of a rapidly evolving market while maintaining product safety and consistency.

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham is a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.