Production Plants - Plant Simulation

Optimise your production processes with Tecnomatix Plant Simulation.

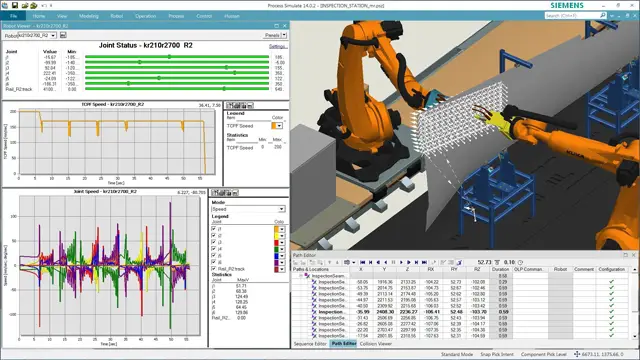

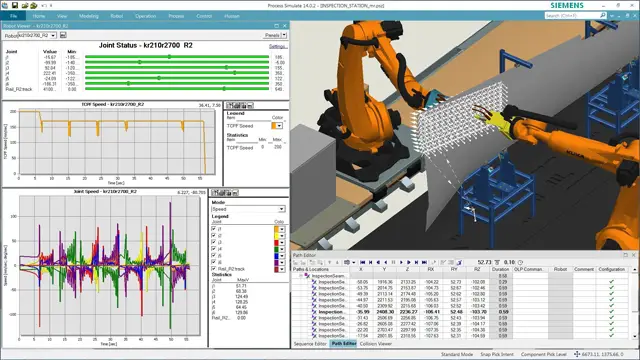

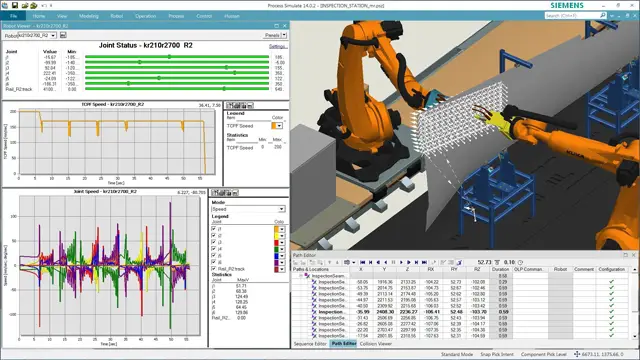

Tecnomatix Plant Simulation empowers you to design, simulate, and optimise your production processes with unparalleled precision. By creating virtual replicas of your manufacturing environment, you can identify bottlenecks, enhance efficiency, and reduce costs before investing in real-world changes.

To purchase Plant Simulation, contact our team.

Tecnomatix Key Features

Risk Mitigation and Cost Reduction

By simulating various scenarios in a virtual environment, you can identify and mitigate potential risk before they impact real-world operations. This leads to significant cost savings and minimises disruptions.

Digital Twin Creation

Plant Simulation lets you build a digital twin of your entire production system. The virtual replica allows you to experiment with scenarios and optimise processes without disrupting real-world operations.

Improved Decision Making

The digital twin provides valuable insights into system behaviour, enabling data-driven decisions based on simulation results. This empowers you to optimise resource allocation, identify bottlenecks, and improve overall system performance.

Why choose Tecnomatix Plant Simulation?

The Tecnomatix Advantage

Improved production efficiency

Virtual simulation and optimisation of complex manufacturing processes lead to higher product quality and consistency.

Reduced production costs

Virtual testing helps identify and address potential risks before physical implementation, reducing the chance of costly errors.

Sustainable production practices

Process Simulate facilitates collaboration between different engineering disciplines, improving communication and efficiency.

Accelerated time-to-market

By virtually validating manufacturing concepts upfront, companies can accelerate product launches and reduce time-to-market.

FREE Trial

Experience the Technomatix Software for FREE*

Tecnomatix Plant Simulation accelerates production planning and optimisation. Our comprehensive simulation platform delivers powerful tools for designing, analysing, and improving manufacturing processes.

*Subject to Terms and Conditions

Case Studies

Continental Automotive Group

Continental Automotive, a global automotive supplier struggled with frequent product changes and production line adjustments. By implementing Tecnomatix Plant Simulation, they overcame these challenges. This digital solution enabled them to simulate material flow, identify bottlenecks, optimise line performance, and make data-driven decisions. As a result, Continental reduced costs, increased efficiency, and accelerated time-to-market.

Bosch Group

Bosch, a global technology leader, struggled to standardise and scale material flow simulation across its production sites. By creating a standard library of simulation objects within Plant Simulation, the company significantly improved efficiency and reduced costs. This approach enabled Bosch to expand its use of simulation, leading to better decision-making and accelerated time-to-market.

Inteco

Inteco, a leading steel mill equipment designer, faced challenges in validating complex plant designs. By implementing Tecnomatix simulation software, the company optimised material flow, provided early proof of concept, and accelerated commissioning. This led to improved project success, reduced costs, and enhanced customer satisfaction.

Build innovative machines faster without costly prototyping with Efficient Motion Control.

With Effective Motion Control, machine builders can easily overcome major challenges and enable faster time-to-market, increased functionality, resolve complex system requirements, and demands for safety and sustainability.

We are Siemens trusted and approved distribution partner.

As a Value Added Reseller in Siemens’ Approved Partner network, Parmley Graham is a proven supplier of a wide range of quality products in the UK and globally.

Find out more how this will benefit you or check Siemens Configurator.